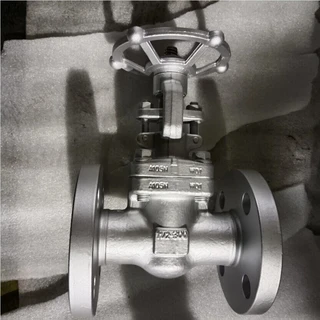

Gate valve is usually divided into rising stem gate valves and nor-rising stem gate valves. The rising stem gate valves is widely used due to easy lubricate and observe, the nor-rising stem gate valves remains at the same height during the opening and closing process, it is suitable for installation where the space is limited.

Gate Valve Design Features:

Disc: flexible wedge by default, solid wedge can be provided upon request.

Seat: Renewable seat and non-renewable seat are both available.

Body - Bonnet Connection: Bolted bonnet (BB) is normally applied on CL150 - CL1500, body bonnet seal is defaulted by gasket and RTJ ring. Pressure seal bonnet is applied on CL1500 - CL2500 with pressure seal ring for connection between body and bonnet.

Packing: graphite packing by default, PTFE packing on corrosive media. API 622 fugitive emission packing can be available upon request.

Back seat: Renewable back seat is applied on carbon steel and low alloy steel valve, integral back seat is applied for stainless steel valve.

Actuation: Hand wheel and gear box are normally designed for cast gate valve based on different size and pressure rating; Electric, pneumatic or Chain wheel operation can be provided upon request.

Product Range:

Size: 2" - 60" (DN50 - DN1500)

Pressure Rating: Class 150 LB - 2500 LB (PN16 - PN420).

Material: Carbon steel, Stainless steel, Alloy steel, including WCB、GS-C25、LCB、LCC、LC1、LC3、CF8、CF8M、CF3、CF3M、WC6、C5、C9、C12、4A、5A、MONEL、ALLOY20、C95800.

Connection End: BW, RTJ, Flanged.

Operation: Handwheel, Gearbox, Electric, Pneumatic.

Design & Manufacture Standard: API 600, ASME B16.34, DIN 3352, EN 1984, Bolted bonnet, pressure bonnet, bellow seal bonnet, high / low temperature extended bonnet and ISO 15848 fugitive emission designed valves are available upon different request of services.

Test Standard: API 598, EN 12266.

The globe valve, also called stop valve, relies on the pressure of the stem, making the sealing surface between disc and seat closely fitted to prevent the circulation of the medium. As the short opening and closing stroke of stem, globe valve has a reliable cut-off function. Due to the change of the valve seat opening is proportional to the stroke of the valve flap, it is suitable for the flow regulation and frequent operation.

Design features:

Disc: Single disc by defaultand double disc is applied for larger pressure difference or bigger size, the flow diretcion can be from lower inlet to higher out let, and from higher inlet to lower outlet is normally used for refinery to ensure the protetc stem seal from leakage.

Flat disc, conical disc, and plug loose type disc can be made upon request.

Seat: Welded seat and integral seat.

Body - Bonnet Connetcion: Bolted bonnet (BB) is normally applied on CL150 - CL900, body bonnet seal is defaulted by gasket and RTJ ring. Pressure seal bonnet (PSB) is applied on CL1500 - CL2500 with pressure seal ring for body bonnet seal.

Packing: By default graphite packing is used, PTFE packing can be used on corrosive media. API 622 fugitive emission packing will be used upon request.

Back seat: Renewable back seat is applied on carbon steel and low alloy steel valve, body back seat is applied for stainless steel valve.

Actuation: Hand wheel and gear box are normally designed for cast gate valve based on different size and pressure rating; Eletcric, pneumatic or Chain wheel operation can be provided upon request.

Product Range:

Size: 2 Inch - 24 Inch (DN50 - DN600).

Pressure Rating: Class 150 LB - 2500 LB (PN16 - PN420).

Material: Carbon steel, Stainless steel, Alloy steel, including WCB, GS-C25, LCB, LCC, LC1, LC3, CF8, CF8M, CF3, CF3M, WC6, C5, C9, C12, 4A, 5A, MONEL, ALLOY20, C95800

Connetcion End: BW, RTJ, Flanged.

Operation: Handwheel, Gearbox, Eletcric, Pneumatic.

Design & Manufacture Standard: ASME B16.34, BS 1873, DIN 3356, Bolted bonnet, pressure bonnet, bellow seal bonnet, high/low temperature extended bonnet and ISO 15848 fugitive emission designed valves are available upon different request of services.

Test Standard: API 598, EN 12266.

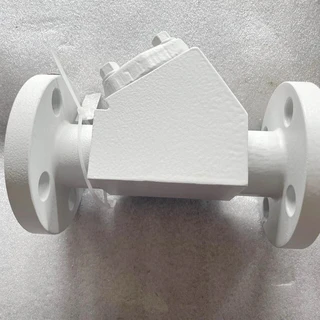

Weldon check valves offer simple structure, less parts, convenient maintenance and repair and low failure rate. The full open disc design is applied to provide a larger opening flow area after disc opening, small fluid resistance and large valve flow coefficient. Counter weight or damp structure can be applied to reduce the impact of water hammer while disc opening.

Product Range:

Size: 2 Inch - 60 Inch (DN50 - DN1500)

Pressure Rating: Class 150 LB - 2500 LB (PN16 - PN420)

Material: Carbon steel, Stainless steel, Alloy steel, including WCB, GS-C25, LCB, LCC, LC1, LC3, CF8, CF8M, CF3, CF3M, WC6, C5, C9, C12, 4A, 5A, MONEL, ALLOY20, C95800

Connetcion End: BW, RTJ, Flanged.

Design & Manufacture Standard: API 6D, DIN 3352, BS 1868.

Test Standard: API 598, EN 12266.

The ball valves are open when the ball's hole is in line with the flow and closed when it is pivoted 90-degrees by the valve handle, the ball is driven by the valve stem and can be closed tightly with a small torque. Due to its ease operation, repair, and versatility, ball valve is widely used in petroleum refining, chemical, eletcric power pipeline to cut, regulate and change the flow diretcion of the medium.

Product Range:

Size: 1/2 Inch - 60 Inch (DN50 - DN1500).

Pressure Rating: Class 150 LB - 2500 LB (PN16 - PN420).

Material: Carbon steel, Stainless steel, Alloy steel, including WCB, GS-C25, LCB, LCC, LC1, LC3, CF8, CF8M, CF3, CF3M, WC6, C5, C9, C12, 4A, 5A, MONEL, ALLOY20, C95800.

Connetcion End: RTJ, BW, Flanged.

Operation: Level, Worm gear, Eletcric, Pneumatic.

Design & Manufacture Standard: API 6D.

Test Standard: API 598, API 6D.

The butterfly valve is similar to ball valve, also called quarter-turn valves. It is fully open or closed when the disc is rotated a quarter turn. Butterfly valve is widely used in the pharmaceutical, chemical, and food industries due to lower cost and ease of installation.

Product Range:

Size: 2 - 120 Inch (DN50 - DN3000).

Pressure Rating: Class 150 - 600 LB (PN16 - PN100).

Material: Cast iron, Carbon steel, Stainless steel, Alloy steel, including WCB, GS-C25, LCB, LCC, LC1, LC3, CF8, CF8M, CF3, CF3M, WC6, C5, C9, C12, 4A, 5A, MONEL, ALLOY20, C95800.

Connection End: Wafer, Lug, Flanged.

Design & Manufacture Standard: API 609.

Test Standard: API 598.

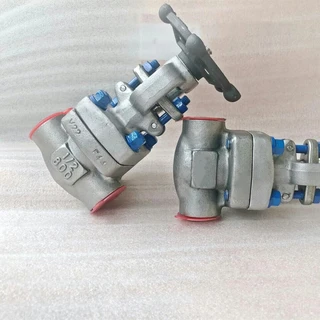

During the forging process, the structure of metal becomes more compact, the plasticity and mechanical properties are improved, the mechanical properties of the forgings are normally higher than castings in same material. Considering the cost factor, forged valves are less than 2 inch, especially for high pressure, preferred for forging.

Product Range:

Size: 1/4 Inch - 2 Inch (DN15 - DN50).

Pressure Rating: Class 150 LB - 2500 LB (PN16 - PN420).

Material: Forged Carbon steel, Stainless steel, Alloy steel, A105N, LF2, F11, F22, F304, F316, F304L, F316L etc.

Connetcion End: NPT, SW, BW, RTJ, RF.

Operation: Handwheel, Eletcric.

Design & Manufacture Standard: API 602.

Test Standard: API 598.

Safety valve is the safe guard in the pressure vessels such as chemical plants, eletcric power boilers and gas storage tanks, acting as a protetcion equipment from exploding or damaging. The safety relief valve is opened automatically to relief when the system pressure exceeds the set pressure, and resumes closed when the system pressure bellow the set pressure.

Product Range:

Size: 1/2 Inch - 24 Inch (DN10 - DN600).

Pressure Rating: Class 150 LB - 2500 LB (0.6 - 42.0 Mpa).

Working Temperature: -196 - 570℃.

Material: Carbon steel, Stainless steel, Alloy steel, including WCB, LCB, LCC, LC1, LC3, CF8, CF8M, CF3, CF3M, WC6, C5, C9, C12, 4A, 5A, MONEL, ALLOY20, C95800, etc.

Connetcion End: Flanged, Thread.

Design & Manufacture Standard: API 520, API 526, API 527.

Apply To: Power Generation, General Industrial, Oil & Gas, Refining, Petrochemical, Chemical, Urea & Paper, Desalination.

Product Range:

Size: 2 Inch - 24 Inch (DN50 - DN600).

Pressure Rating: Class 150 LB - 600 LB (PN16 - PN100).

Material: Carbon steel, Stainless steel, Alloy steel, including WCB, GS-C25, LCB, LCC, LC1, LC3, CF8, CF8M, CF3, CF3M, WC6, C5, C9, C12, 4A, 5A, MONEL, ALLOY20, C95800, etc.

Connetcion End: BW, RTJ, Flanged.

Design & Manufacture Standard: ASME B16.34, DIN 3352.

Test Standard: API 598, EN 12266.

Product Range:

Size: 2 Inch - 12 Inch (DN50 - DN300)

Pressure Rating: Class 150 LB - 4500 LB (PN16 - PN760)

Material: Carbon steel, Stainless steel, Alloy steel, including WCB, GS-C25, LCB, LCC, LC1, LC3, CF8, CF8M, CF3, CF3M, WC6, C5, C9, C12, 4A, 5A, MONEL, ALLOY20, C95800, etc.

Connetcion End: Flanged.

Design & Manufacture Standard: ASME B16.34

Test Standard: MSS SP 61.

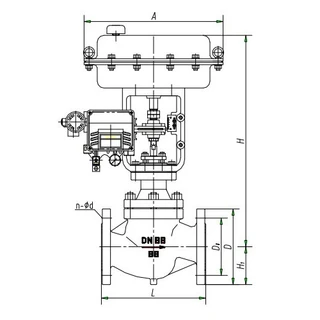

Based on travel characteristics, control valves can be categorized into linear control valves and angle control valves. According to different operations, they can be classified as pneumatic control valves, electric control valves, and hydraulic control valves. In terms of function and characteristics, control valves are further divided into three types: linear characteristic, equal percentage characteristic, and parabolic characteristic.

A control valve comprises actuator and valve body components, where the actuator serves as the driving device. It generates thrust based on the signal pressure, causing the push rod to undergo corresponding displacement and, in turn, driving the spool of the control valve into action.

As a leading manufacturer and supplier of control valves in China, Weldon Control Valve stands out for its simple structure, reliable and stable action, substantial output force, easy installation and maintenance, cost-effectiveness, and fire-proof properties. These control valves are suitable for a wide range of applications, including air, water, steam, various corrosive media, slurry, oil, and more. Control valves play a vital role in the automatic control of modern factories, making them the most widely used type of final control element.

Ceramic lined valves are advanced valve products constructed using high-tech ceramic materials for their sealing components and vulnerable parts. These valves are designed to significantly enhance wear resistance, corrosion resistance, and sealing performance compared to traditional valve materials. By integrating ceramics into their construction, ceramic lined valves offer extended service life, reduce the frequency of maintenance and replacement, and contribute to the safety and stability of equipment operating systems. They are particularly valued for their ability to lower equipment repair costs over time.

Built with high-tech ceramic materials, these valves withstand corrosive environments and resist abrasion, ensuring durability in harsh conditions.

Capable of operating at elevated temperatures without compromising performance, making them suitable for diverse industrial applications.

Designed to endure mechanical shocks and impacts, enhancing reliability under challenging operational conditions.

Significantly reduces maintenance and replacement costs over time, thanks to their extended service life and robust performance.

It offers a 2-4 times longer lifespan than valves made from specialty alloys, ensuring prolonged reliability and operational efficiency.

Exhibits excellent resistance to a wide range of chemicals, maintaining integrity in aggressive chemical environments.

Incorporates self-lubricating properties, reducing friction and wear between moving parts, thereby enhancing operational efficiency and longevity.