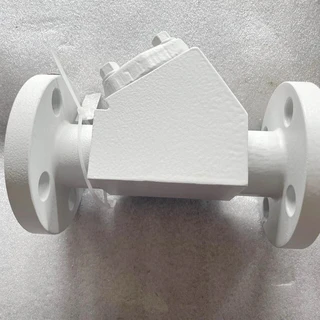

Check Valve

Weldon check valves offer simple structure, less parts, convenient maintenance and repair and low failure rate. The full open disc design is applied to provide a larger opening flow area after disc opening, small fluid resistance and large valve flow coefficient. Counter weight or damp structure can be applied to reduce the impact of water hammer while disc opening.

Product Range:

Size: 2 Inch - 60 Inch (DN50 - DN1500)

Pressure Rating: Class 150 LB - 2500 LB (PN16 - PN420)

Material: Carbon steel, Stainless steel, Alloy steel, including WCB, GS-C25, LCB, LCC, LC1, LC3, CF8, CF8M, CF3, CF3M, WC6, C5, C9, C12, 4A, 5A, MONEL, ALLOY20, C95800

Connetcion End: BW, RTJ, Flanged.

Design & Manufacture Standard: API 6D, DIN 3352, BS 1868.

Test Standard: API 598, EN 12266.

Weldon wafer check valve offers easy assembly and maintenance as well as quick open and close. Single disc wafer, dual wafer, axial flow, quick opening and slow closing action with damping check are available based on different request of service.