Pressure seal valves have become a crucial component in various industries, particularly in power generation, refineries, chemical processing, and steam generation systems. Unlike conventional body-to-bonnet sealing mechanisms, pressure seal valves are designed to perform efficiently under high-pressure conditions, ensuring reliable sealing and preventing leaks. In applications where internal pressures are high, the potential for leaks increases, making the need for durable, high-performing valves essential.

As system pressures rise, so does the stress on valves, and with that comes the risk of fatigue, wear, and potential failure. Pressure seal check valves address these challenges, offering an efficient, cost-effective solution for industries requiring robust performance. These valves are particularly advantageous in systems with a minimum pressure of 500 psi, providing excellent reliability and durability. Furthermore, their unique design minimizes maintenance needs, contributing to long-term cost savings.

Pressure seal check valves come in a variety of materials, designs, and pressure ratings to meet the needs of different applications. These valves are commonly found in power plants, pulp and paper mills, refineries, and chemical processing plants, where reliable, non-leaking valves are essential. This article explores the importance of pressure seal check valves, their working principle, types, applications, and benefits, offering a comprehensive overview of how they contribute to safe and efficient system operations.

A pressure seal check valve is a type of valve designed to allow fluid to flow in only one direction. Its primary function is to prevent backflow, which can lead to system contamination, damage to equipment, and operational inefficiencies. The valve typically employs a disc or ball mechanism that opens and closes in response to the flow direction, ensuring unidirectional fluid flow.

The design of a pressure seal check valve is particularly suited for systems where internal pressures are high, as the pressure helps maintain a reliable seal between the valve body and bonnet. As internal pressure increases, the valve's seal tightens, creating a more secure closure. This feature is especially important in high-pressure applications, such as steam or gas systems, where conventional sealing mechanisms may fail to provide the necessary leak-proof performance.

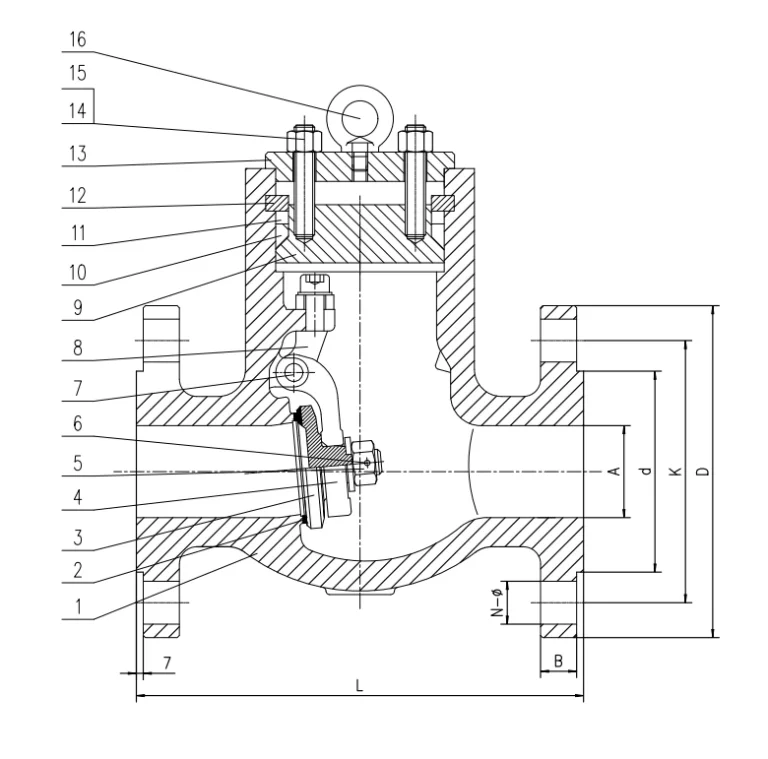

Pressure seal check valves come in various types, including swing-type, piston-type, and lift-type valves. Each type is designed to address specific system requirements and operational needs. The valve's construction typically includes a robust body and bonnet design, capable of withstanding high-pressure conditions, ensuring long-lasting performance and minimal maintenance.

Pressure seal check valves are available in different types, each designed for specific operational needs. These valves are categorized primarily based on their mechanism of operation, such as swing, piston, or lift types.

A swing check valve operates using a hinged disc that swings open and closed based on the direction of the fluid flow. When fluid flows in the intended direction, the disc swings open, allowing passage. If the flow reverses, the disc swings back and closes off the passage, preventing backflow. Swing check valves are ideal for use in large pipelines where the fluid's flow rate is consistent, and minimal resistance to flow is required.

Applications: Swing check valves are commonly used in steam, water, and gas systems, particularly in power generation and refinery applications. They are best suited for applications where the flow is generally one-way and where the system pressure does not fluctuate rapidly.

Piston check valves use a piston mechanism to allow flow in one direction and prevent backflow in the opposite direction. The piston moves within the valve body and is held in place by the system's pressure. Piston check valves are more resistant to vibration and are ideal for high-pressure systems where there is a need for precise control of fluid flow.

Applications: Piston check valves are commonly used in applications with high differential pressures, such as in oil and gas, chemical processing, and water treatment plants. They are ideal for situations where backflow prevention is crucial, and operational reliability is a must.

A lift check valve uses a vertically moving disc or piston that is lifted by the fluid flow in the forward direction. When the flow reverses, the disc or piston closes off the flow passage to prevent backflow. Lift check valves are often used in systems with high pressure or where there are space constraints, as their design allows for vertical installation.

Applications: Lift check valves are typically used in smaller pipelines and systems with high-speed flow, such as in water or steam systems within industrial facilities. They are suitable for both horizontal and vertical installations.

Pressure seal check valves operate on the basic principle of allowing fluid to flow in only one direction while preventing backflow. The mechanism is dependent on the system's internal pressure to ensure a tight, reliable seal between the valve body and bonnet. As the internal pressure increases, the seal becomes more secure, providing better performance in high-pressure environments.

When fluid flows in the intended direction, the internal mechanism (a disc, ball, or piston) is forced open, allowing passage. When the flow reverses, the pressure helps the valve mechanism to close tightly, creating a seal that prevents backflow and protects the system. The valve's body and bonnet are designed to withstand high pressure, ensuring long-term reliability and performance.

Pressure seal check valves are designed with a specific pressure rating to ensure they can withstand the demands of different applications. For systems operating with pressures above 500 psi, pressure seal check valves offer the best solution due to their ability to handle high-pressure conditions without compromising sealing effectiveness.

Pressure seal check valves are essential components in various high-pressure systems. Their primary function is to prevent backflow and ensure that fluids only flow in the intended direction. Below are some common applications of pressure seal check valves:

In power generation plants, pressure seal check valves are used in steam and water systems to prevent backflow and ensure efficient flow of steam or water. These valves are crucial in maintaining the integrity of the system, protecting pumps, turbines, and other critical components from damage caused by backflow. Pressure seal check valves are particularly beneficial in high-pressure steam systems, where the internal pressure is high, and leaks can cause operational inefficiencies or equipment failure.

Pressure seal check valves are used in refineries and chemical processing plants to maintain the integrity of fluid systems, such as oil, gas, and chemical pipelines. These valves prevent backflow in crucial processes like distillation, catalytic reforming, and cracking, where flow direction must be carefully controlled to ensure the quality of the end product. The valves are also critical in protecting the system from contamination, which can result from reverse flow.

In water treatment plants, pressure seal check valves are used in filtration and distribution systems to prevent reverse flow, which could result in contamination of treated water. These valves help maintain the quality of the water and protect equipment such as pumps and pipelines from damage caused by backflow.

Pulp and paper mills rely on pressure seal check valves to control fluid flow and maintain the efficiency of their high-pressure systems. These valves are used in processes such as bleaching, chemical treatment, and drying, where maintaining a consistent flow direction is essential for producing high-quality paper products.

The oil and gas industry relies on pressure seal check valves to ensure the safe and efficient transport of crude oil, natural gas, and refined products through pipelines. These valves help prevent backflow, which could cause system contamination, equipment damage, or hazardous situations.

Leak Prevention: Pressure seal check valves ensure a tight seal that prevents leaks, even under high-pressure conditions.

High-Pressure Performance: These valves are designed to withstand pressures above 500 psi, making them ideal for high-pressure systems.

Reduced Maintenance: The pressure-sealing mechanism reduces wear and tear on the valve, leading to lower maintenance costs and longer service life.

Enhanced System Safety: By preventing backflow, pressure seal check valves protect system components from potential damage caused by reverse flow.

Improved Operational Efficiency: These valves ensure the proper direction of fluid flow, preventing contamination and system inefficiencies.

Pressure seal check valves are integral components in various high-pressure systems, including power generation, refineries, chemical processing, and water treatment plants. With their ability to handle high internal pressures and provide a reliable seal, these valves prevent backflow, protect equipment, and ensure the smooth operation of fluid systems. The range of valve types, including swing, piston, and lift designs, allows manufacturers to select the most appropriate valve for their specific applications, ensuring optimal performance and efficiency.

As industries continue to demand higher operational efficiencies, pressure seal check valves will remain essential for preventing leaks, reducing maintenance costs, and ensuring the safety and longevity of high-pressure systems. Whether in power generation, refineries, or water treatment, these valves are designed to provide the utmost reliability in challenging environments.