Inspection of the Globe Valve Crack in the Main Steam Pipe of the Boiler

- Sep 01, 2024

- Hits: 3

A valve is an essential pressure-bearing component of the boiler and is suspended on the boiler’s pipeline. If the valve body leaks or cracks during operation, it can pose significant risks...

A Complete Guide to Ball Valve Maintenance

- Aug 30, 2024

- Hits: 109

Ball valves are a type of valve widely used in industrial piping systems. Its basic structure consists of a ball and a seat, and the ball has a hole in the center. The flow of fluid is controlled by rotating...

How to Choose Valve Material Based on Your Requirements

- Aug 27, 2024

- Hits: 23

In the selection of valves, the difference in material will directly affect the long-term efficiency and performance of the equipment. Cast iron, ductile iron, bronze and stainless steel and other metals,...

Five Reasons for Safety Valve Failure

- Aug 20, 2024

- Hits: 63

In the manufacturing and food industries, work-related accidents are often related to safety valve failures. While these devices are critical in gas, liquid and steam handling systems, they can fail for...

Complete Guide to Cryogenic Ball Valve Maintenance

- Aug 14, 2024

- Hits: 50

Cryogenic ball valves play an important role in fluid control at extremely low temperatures, and their stability and functionality are directly related to safety and equipment reliability. In order to...

Analyzing Rust on the Sealing Surface of Nuclear-grade SS Globe Valves

- Aug 07, 2024

- Hits: 8

1. Overview Globe valves are widely used in nuclear power plant pipeline systems due to their minimal mechanical wear on the sealing surface and ease of maintenance. However, nuclear-grade stainless steel...

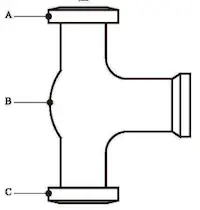

Designing A Multifunctional Valve

- Aug 02, 2024

- Hits: 13

Abstract: To control the connection or disconnection of solid particle wastewater in the system pipeline and prevent the backflow of seawater, effectively ensuring the long-term stable operation...

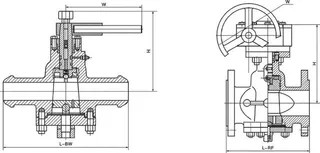

Complete Guide to Lubricated Plug Valves

- Jul 31, 2024

- Hits: 112

The plug valve is one of the oldest valves in use today and is mainly used to quickly close the flow of liquids. The plug valve starts or stops the flow by a quarter-turn rotating motion and consists...

Characteristics and Applications of Bellows Sealed Globe Valves

- Jul 31, 2024

- Hits: 22

In industrial operations where fluid control plays an important role, the globe valve is a key component for reliability and safety. Among various types of globe valves, bellows sealed globe valves have...

Processing Sealing Surfaces of Triple Eccentric Metal Seated Butterfly Valves

- Jul 29, 2024

- Hits: 14

A valve is a pipeline accessory used to control and transport media. Valves are widely used in industrial and agricultural development, cutting-edge defense technology, transportation, and everyday...

The Essential Role of Plug Valves in Fluid Control Systems

- Jul 24, 2024

- Hits: 7

Fluid control systems are an integral part of many industries, ensuring seamless operation of processes from manufacturing to energy production. At the heart of these systems are the plug valves, known...

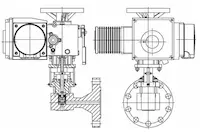

A Comprehensive Guide to Electric Control Valves

- Jul 24, 2024

- Hits: 58

Electric control valves are automated devices designed to regulate liquid and gas flow in a wide range of industrial applications. By using electrical current to open or close ports, these valves can...