Lift check valves are specialized industrial valves designed to permit fluid flow in one direction while automatically preventing backflow when conditions change. They achieve this by opening during normal forward flow and closing under low-flow or reverse-flow conditions. Their defining characteristic is that they must be installed horizontally—gravity plays a key role in assisting the closure of the valve.

These valves are widely used across a variety of industries, including water supply, chemical processing, steam power generation, oil and gas, and wastewater treatment. Their role is critical in maintaining system efficiency, preventing contamination, and protecting expensive equipment from damage caused by reverse flow.

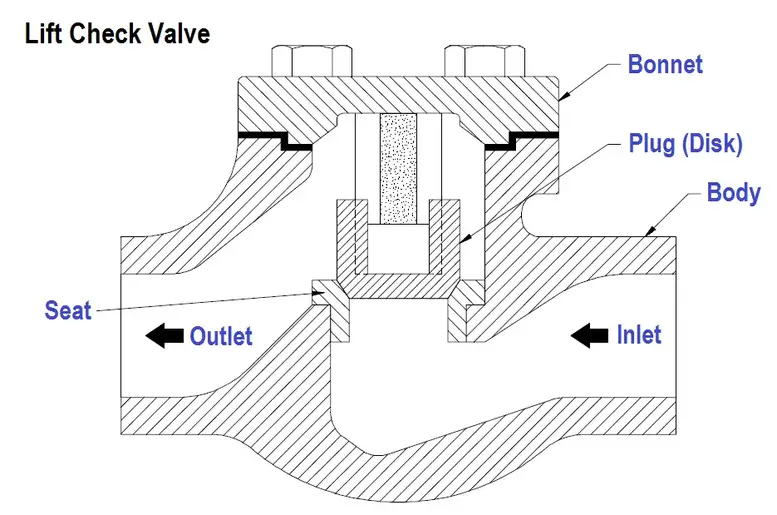

Structurally, the disc seat of a lift check valve rests against the sealing surface of the valve seat within the valve body. In normal operation, fluid pressure lifts the disc away from the seat, allowing flow. When backflow occurs or pressure drops, the disc falls back into place, shutting off the passage. While this mechanism resembles that of a globe valve in appearance, the key difference lies in how the disc operates—here, it moves freely rather than being operated by an actuator.

Like globe valves, lift check valves have a relatively narrow fluid passage, which means they typically cause a higher pressure drop than swing check valves. However, their precise sealing and robustness make them ideal for demanding applications. Depending on service conditions, the disc can be all-metal or fitted with a rubber pad or sealing ring to improve tightness.

Lift check valves consist of several key parts, each designed to withstand specific operating stresses:

The valve body houses all internal components and maintains structural integrity under high pressure.

Material: One of the most common materials for lift check valve bodies is gunmetal, an alloy of copper, tin, and zinc (typically 88% copper, 8–10% tin, and 2–4% zinc). Gunmetal is prized for its corrosion resistance and resistance to dezincification, making it suitable for water, steam, and chemical applications.

Other options: Stainless steel, bronze, and cast iron are also used, depending on temperature, pressure, and fluid properties.

The disc is the moving part that responds to fluid pressure. In lift check valves, the disc can be plug-shaped or ball-shaped.

During forward flow, fluid pressure lifts the disc to allow passage.

During reverse flow, gravity and pressure differences cause the disc to return to the seat, sealing the passage.

The seat is the surface against which the disc seals. Precision machining is crucial to ensure a leak-free seal. Seats may be:

Integral: Machined directly into the valve body.

Renewable: Made from replaceable inserts, often hardened steel or elastomer materials, for easier maintenance.

While the basic principle remains the same, there are several variations designed to suit different operational needs:

Feature a basic vertical disc lift mechanism.

Ideal for simple applications with consistent flow conditions.

Incorporate a spring to assist in disc closure.

The spring provides faster response, reducing the risk of reverse flow and water hammer.

Common in high-speed flow systems or where rapid closure is critical.

Designed with a 90-degree change in flow direction within the body.

Useful for installations where space constraints prevent the use of straight-through valves.

Lift check valves operate based on differential pressure—the pressure upstream of the valve must be greater than the pressure downstream for fluid to pass through.

As upstream pressure rises, the force overcomes the weight of the disc (and spring, if present), lifting it from the seat.

The valve opens to allow forward flow.

When downstream pressure exceeds upstream pressure—or if flow stops—the pressure differential reverses.

Gravity (and/or the spring) causes the disc to drop back onto the seat, blocking reverse flow.

For stability and alignment, many lift check valves feature guide ribs inside the body. These ensure the disc moves vertically without tilting or jamming, maintaining consistent performance over time.

Lift check valves are valued for their reliability, durability, and versatility. They can be installed in both horizontal and certain vertical pipelines (if upward flow is maintained). They are especially suited for high-velocity fluids such as steam, air, and gas.

Key Industry Applications:

Prevents backflow in potable water networks, safeguarding water quality.

Protects pumps from damage due to reverse water hammer.

Controls the one-way flow of chemicals in production lines.

Prevents cross-contamination between different chemical streams.

Maintains flow integrity in crude oil, refined fuel, and gas pipelines.

Prevents costly downtime caused by contamination or reverse pressure surges.

Ensures sterility by preventing backflow of process fluids.

Often paired with sanitary-grade materials and precision finishes.

Maintains correct steam direction in turbines and boilers.

Reduces risk of mechanical stress caused by steam reversal.

Prevents untreated wastewater from flowing back into clean water systems.

Helps maintain stable treatment processes in pump stations.

Durability: Solid construction ensures long service life, even under high pressure and temperature.

High-Pressure Capability: Performs well in demanding industrial environments.

Leak-Tight Seal: Precision seating surfaces offer excellent sealing performance.

Low Maintenance: Few moving parts mean minimal wear and reduced servicing needs.

Versatility: Suitable for a wide range of fluids—liquids, gases, and steam.

High Pressure Drop: Due to the narrow flow path, lift check valves cause greater resistance than swing check valves.

Water Hammer Risk: Rapid closure can cause hydraulic shock; mitigation measures may be necessary.

Debris Sensitivity: Solid particles in the fluid can lodge in the seat, preventing full closure. Pre-filtration is often required.

Orientation Restrictions: Most designs require horizontal installation for proper operation.

Proper installation is essential to ensure that lift check valves perform reliably and maintain system efficiency over time. Following the correct procedures helps prevent premature wear, leakage, or operational failures.

Lift check valves can generally be installed in either horizontal or vertical piping configurations. However, they deliver optimal performance in horizontal systems, where gravity naturally assists the disc in returning to the closed position during backflow conditions. In vertical installations, the valve should only be used in upward flow applications to ensure proper operation. Always follow the manufacturer’s specific orientation recommendations to avoid operational issues.

Before installation, assess the flow rate, system pressure, and fluid type to determine the most suitable valve design and size. For example:

High-pressure or high-temperature systems may require all-metal discs and seats.

Corrosive or chemical applications may need bodies and internal components made from stainless steel or corrosion-resistant alloys.

Clean water or steam systems may work well with standard gunmetal or bronze-bodied valves.

Ensure the pipeline is free from debris, welding slag, or scale, as these can damage the seating surface or hinder disc movement. Installing a strainer upstream of the valve is strongly recommended, especially in systems prone to carrying particulate matter.

Align the valve carefully to avoid stress on the body. Use appropriate gaskets and tighten bolts evenly to prevent distortion or leakage.

By following these guidelines, operators can maximize the efficiency, service life, and reliability of lift check valves, ensuring consistent one-way flow and effective backflow prevention in any industrial piping system.

Proper operation and longevity of a lift check valve depend heavily on correct installation and maintenance practices:

Ensure horizontal orientation unless the manufacturer specifies vertical compatibility.

Install strainers upstream to remove solids.

Periodically inspect for wear on the seat and disc.

Clean internal components to prevent fouling.

Use dampers or slow-closing actuators where sudden flow changes occur.

Choose body and seat materials compatible with the fluid’s chemical composition and temperature.

Lift check valves may seem like simple mechanical devices, but their contribution to industrial safety and efficiency is profound. By allowing flow in one direction and reliably blocking reverse flow, they protect pumps, compressors, boilers, and entire process lines from costly and potentially dangerous damage.

Whether used in a municipal water system, a high-pressure steam plant, or a precision pharmaceutical line, lift check valves stand as a quiet yet essential safeguard in fluid handling systems. When properly selected, installed, and maintained, they offer decades of dependable service—a testament to the enduring value of sound engineering in industrial valve design.