In modern industrial piping systems, efficiency, reliability, and compact design are more important than ever. As processes become more complex and space constraints tighten, engineers and plant operators are increasingly looking for valve solutions that can perform multiple functions without adding unnecessary complexity to the pipeline. Multi-port ball valves have emerged as one of the most effective answers to this challenge.

Unlike conventional two-way ball valves that simply start or stop flow, multi-port ball valves are designed to control, divert, mix, or distribute fluids between multiple pipelines using a single valve body. Available in 3-way, 4-way, and even 5-way configurations, these valves offer exceptional flexibility while maintaining the core advantages of ball valve technology—tight shut-off, quick operation, and robust construction. By replacing multiple standard valves with a single multi-port unit, users can significantly reduce installation costs, simplify automation, and improve long-term maintenance efficiency.

This article provides a comprehensive overview of multi-port ball valves, including their design principles, configurations, working mechanisms, advantages, applications, and selection considerations. Whether used in chemical processing, oil and gas systems, water treatment, or industrial automation, multi-port ball valves play a critical role in optimizing flow control strategies.

Multi-port ball valves are advanced ball valves that feature more than two ports within a single valve body. While standard ball valves typically have one inlet and one outlet, multi-port designs incorporate three, four, or five ports, allowing flow to be redirected in multiple directions.

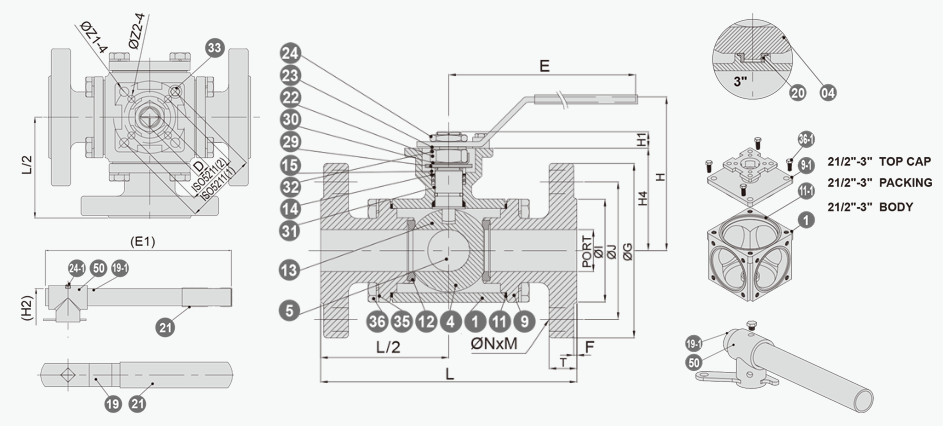

These valves are commonly manufactured as 2-piece or 3-piece constructions and use a full-bore or reduced-bore ball with specially machined flow passages. The ball rotates inside the valve body, aligning internal passages with specific ports to achieve the desired flow path. Depending on the design, a single quarter-turn or multi-position rotation can connect, isolate, or divert fluid streams.

Because of their ability to manage multiple flow paths, multi-port ball valves are often described as multi-directional control valves with shut-off capability. This combination makes them particularly valuable in systems that require frequent switching between pipelines or operational modes.

3-way ball valves are the most widely used type of multi-port ball valve. They typically feature three ports arranged in either an L-pattern or a T-pattern:

- L-Port (90-degree flow): Allows flow to be directed from one inlet to one of two outlets, but not both simultaneously. This configuration is ideal for flow switching applications.

- T-Port (180-degree or multi-directional flow): Allows flow to be mixed, diverted, or split, depending on the internal ball design and rotation angle.

3-way valves are commonly used in heating systems, process lines, and distribution networks where controlled flow diversion is required.

4-way ball valves are true multi-port valves with seals on each port. They allow more complex flow routing and can often replace up to four conventional 2-way valves. These valves are particularly useful in applications that require alternating flow paths or reversing flow direction without reconfiguring piping.

Because of their ability to consolidate multiple valves into one unit, 4-way ball valves significantly reduce the number of fittings, flanges, and potential leak points in a system.

5-way ball valves are used in highly specialized applications where multiple flow paths must be managed simultaneously. Although less common, they are invaluable in complex process systems, test rigs, and automation setups where space efficiency and precise flow control are critical.

Multi-port ball valves share many design elements with standard ball valves but incorporate additional features to support multi-directional flow.

Many multi-port ball valves use a full-bore ball, meaning the internal diameter of the flow passage matches the pipeline diameter. This minimizes pressure drop and allows high flow rates to pass through the valve without restriction.

The internal ball is machined with L-shaped, T-shaped, or custom flow channels to achieve specific flow patterns. High machining accuracy ensures smooth operation and consistent sealing.

Each port is equipped with high-performance seals, often made from PTFE, reinforced PTFE, or other engineered polymers. For high-temperature or corrosive applications, metal-seated designs may be used.

Multi-port ball valves are available in a wide range of materials, including carbon steel, stainless steel, duplex stainless steel, and special alloys. Material selection depends on the operating pressure, temperature, and fluid characteristics.

Common end connections include flanged, threaded, socket weld, butt weld, and wafer designs. This flexibility allows easy integration into existing piping systems.

The operation of a multi-port ball valve is based on the rotation of the ball within the valve body. When the handle or actuator turns the stem, the ball rotates accordingly, aligning its internal flow passages with specific ports.

For example:

In one position, the inlet may connect to outlet A.

In another position, the inlet may connect to outlet B.

In certain configurations, multiple ports may be connected simultaneously for mixing or splitting flows.

In the fully closed position, all ports are isolated, providing reliable shut-off.

The number of operational positions depends on the valve design and the required flow patterns. Some multi-port valves are designed with fixed rotation angles, while others allow customized flow paths for specialized applications.

One of the most significant benefits of multi-port ball valves is their ability to replace multiple conventional 2-way valves. By consolidating several valves into a single unit, users can reduce the number of pipes, fittings, flanges, and supports required. This not only lowers material costs but also shortens installation time.

In compact systems or skid-mounted equipment, space is often limited. Multi-port ball valves offer a compact solution by performing multiple flow control functions within a single valve body.

Fewer valves and fittings mean fewer potential leak points. This improves overall system reliability and reduces the risk of maintenance-related downtime.

Multi-port ball valves are well-suited for automation. A single actuator can replace multiple actuators required for individual valves, simplifying control logic and reducing automation costs.

Thanks to full-bore designs, multi-port ball valves can handle high flow rates with minimal pressure loss, making them ideal for demanding industrial applications.

Quarter-turn operation ensures quick and intuitive control. Additionally, many designs allow for easy disassembly and maintenance without removing the valve from the pipeline.

Multi-port ball valves are used across a wide range of industries due to their versatility and efficiency.

- Chemical and Petrochemical Processing: Used for routing process fluids, switching between tanks, and managing batch operations.

- Oil and Gas Industry: Applied in pipeline systems, sampling lines, and flow diversion systems where reliability and tight shut-off are critical.

- Water and Wastewater Treatment: Ideal for flow distribution, backwashing systems, and process optimization.

- HVAC and Energy Systems: Commonly used for heating and cooling circuits, thermal storage systems, and energy distribution networks.

- Food and Beverage Industry: Employed in hygienic flow control applications where frequent switching and cleaning are required.

- Industrial Automation and Testing Systems: Essential in test benches, calibration systems, and automated process lines requiring flexible flow routing.

Choosing the right multi-port ball valve requires careful evaluation of several factors:

Number of Ports and Flow Pattern: Determine whether a 3-way, 4-way, or 5-way configuration is required and select the appropriate internal ball design.

Pressure and Temperature Ratings: Ensure the valve meets or exceeds the system’s operating conditions.

Material Compatibility: Select materials that are resistant to corrosion, erosion, and chemical attack from the process media.

Sealing Requirements: Consider soft-seated versus metal-seated designs based on temperature, pressure, and shut-off requirements.

Actuation Method: Manual, pneumatic, or electric actuators may be chosen depending on automation needs.

Standards and Certifications: Compliance with relevant industry standards ensures safety, performance, and regulatory acceptance.

Multi-port ball valves represent a smart and efficient solution for modern flow control challenges. By combining multiple flow paths, shut-off capability, and robust ball valve performance into a single unit, they offer significant advantages in terms of cost savings, space efficiency, and operational flexibility. From simple flow switching to complex process routing, these valves enable engineers to design cleaner, more reliable, and more economical piping systems.

As industries continue to demand higher efficiency and smarter system design, the role of multi-port ball valves will only become more prominent. By understanding their configurations, working principles, and application benefits, users can make informed decisions and fully leverage the value these versatile valves bring to industrial fluid control systems.