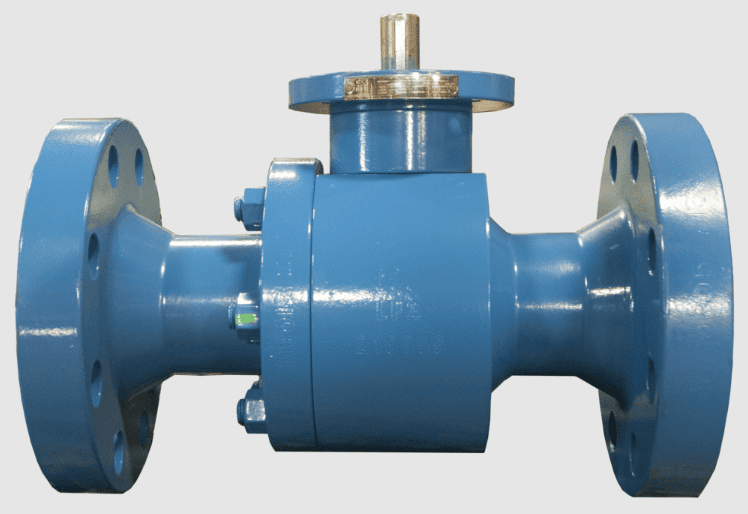

In modern industrial operations, efficiency and safety hinge on the ability to regulate fluid flow with precision. Among the many valve technologies available, the floating ball valve stands out as a reliable, versatile, and cost-effective option for shutting off and regulating liquids and gases across a wide range of industries. Known for its compact design and excellent sealing ability, the floating ball valve is widely used in oil and gas, petrochemical, water treatment, power generation, and many other sectors.

So, what makes a floating ball valve unique? At its core, this type of quarter-turn shutoff valve differs from other ball valve designs in one key aspect: the ball is not anchored or fixed by a shaft or trunnion. Instead, it is held in position only by the valve seats. This floating design allows the ball to shift slightly under fluid pressure, automatically pressing against the downstream seat to create a tight seal. The result is a self-centering, pressure-activated sealing mechanism that ensures reliable isolation in pipelines.

In this article, we will explore the design, components, working principle, advantages, limitations, applications, and future outlook for floating ball valves.

A floating ball valve is a quarter-turn valve that controls the flow of fluid using a hollow, pivoting ball inside the valve body. When the valve handle is rotated 90 degrees, the ball either aligns with the pipeline to allow flow or turns perpendicular to block it.

Unlike trunnion-mounted ball valves, where the ball is fixed by shafts at both ends, the ball in a floating ball valve is free to move slightly along the pipeline axis. Under the pressure of the fluid, the ball is pushed against the downstream seat, creating a tight seal. This self-energized sealing mechanism means that the valve can provide excellent shutoff performance without the need for complex designs.

Floating ball valves are particularly effective in moderate-pressure systems and are valued for their simple construction, easy operation, and reliable performance.

Each component of a floating ball valve is carefully engineered for durability, corrosion resistance, and compatibility with the fluid being controlled. The main parts include:

The valve body is the main casing that houses all internal components. Common materials include carbon steel, stainless steel, alloy steel, and cast iron. The choice of body material depends on application factors such as temperature, pressure rating, and chemical compatibility.

The ball is the critical flow-control element. Typically made from stainless steel, brass, or bronze, the ball may also feature coatings such as chrome plating or special surface treatments to enhance wear resistance and sealing performance.

The valve seats provide the sealing surfaces against which the ball presses when closed. They are commonly manufactured from resilient, chemically resistant materials such as PTFE (Teflon), reinforced PTFE, PEEK, or elastomers like Viton and EPDM.

The stem connects the actuator or handle to the ball, allowing torque to be transferred to rotate the ball. Stems are made from corrosion-resistant alloys to ensure long service life even in aggressive environments.

Stem packing and seals prevent leakage from the valve body. Materials like PTFE, graphite, Nitrile, Viton, and EPDM are commonly used depending on temperature and chemical conditions.

Floating ball valves can be operated manually with a lever or wrench, or automated with gearboxes, pneumatic actuators, or electric actuators. Automation is often used in industrial plants where precise or remote operation is needed.

Floating ball valves come in several construction types, each with specific advantages:

Made from a single forged or cast steel body.

Compact and cost-effective, but cannot be disassembled for cleaning or repair.

Best suited for small applications and gas services requiring minimal maintenance.

Constructed from two housing pieces, with one larger piece containing the ball and moving parts.

Can be disassembled for maintenance or repair but requires removal from the pipeline.

More versatile than the one-piece design, commonly used in liquid pipelines.

Built from three separate body pieces bolted or forged together.

Allows easy access for cleaning, repair, or part replacement without removing the valve from the pipeline.

More expensive but highly practical in industries where regular maintenance is required.

The working principle of a floating ball valve is relatively simple:

Open Position: The handle or actuator rotates the ball so that the hollow bore aligns with the pipeline, allowing fluid to flow freely.

Closed Position: When the ball is rotated 90 degrees, the bore becomes perpendicular to the pipeline, blocking flow.

Sealing Action: As fluid pressure builds, the ball is pushed slightly downstream against the seat, creating a tight seal.

This automatic pressure-assisted sealing mechanism makes floating ball valves particularly effective at achieving bubble-tight shutoff.

Floating ball valves offer several benefits that make them popular in industrial settings:

Simple Design – Fewer components compared to trunnion-mounted designs, reducing cost and maintenance.

Compact Size – Ideal for installations where space is limited.

Excellent Sealing – Pressure-energized sealing ensures reliable shutoff, even with relatively low operating torque.

Versatility – Suitable for both liquids and gases across various industries.

Ease of Operation – Quick quarter-turn operation allows rapid opening and closing.

Cost-Effective – Lower manufacturing and maintenance costs compared to more complex valves.

While effective, floating ball valves also have some limitations:

Pressure Limits – Not suitable for very high-pressure applications, as excessive pressure can cause seat deformation.

Torque Requirement – Larger sizes may require higher torque to operate, especially under high pressure.

Seat Wear – Continuous exposure to abrasive fluids or frequent cycling can wear down soft seats.

Size Constraints – Typically manufactured in smaller to medium sizes (up to about 12 inches) for practical use.

Floating ball valves are used in a wide range of industries, including:

Oil and Gas – Isolation of pipelines, refineries, and storage facilities.

Petrochemicals and Chemicals – Controlling corrosive fluids, acids, and solvents.

Water and Wastewater – Reliable shutoff in treatment plants and distribution systems.

Power Generation – Steam and cooling water systems.

Pharmaceuticals and Food Processing – Hygienic fluid handling where cleanliness and safety are critical.

HVAC Systems – Used in heating, ventilation, and cooling pipelines for efficient flow control.

Proper maintenance is essential to maximize the service life and performance of floating ball valves. Since these valves are widely used in industries handling liquids, gases, and corrosive media, regular care helps prevent downtime and ensures safe, reliable operation.

One of the most important practices is regular inspection, where operators check for external leaks, internal seat wear, corrosion, or signs of damage to seals and packing. Early detection of these issues allows for timely corrective action, avoiding costly system failures.

Another critical step is seat replacement. The soft seats, often made of PTFE or elastomers, are subject to wear and degradation, especially in abrasive or chemically aggressive services. Replacing them at scheduled intervals ensures continued tight sealing and reduces leakage risk.

Stem packing adjustment is also necessary, as stem seals can loosen over time, leading to leakage around the valve stem. Tightening or replacing the packing maintains the integrity of the valve.

In addition, cleaning is recommended in industries where residues, sediments, or deposits may accumulate and interfere with smooth operation.

Among the various designs, three-piece floating ball valves are especially valued because they allow for easy disassembly, cleaning, and part replacement without removing the valve from the pipeline.

A common question in valve selection is whether to use a floating or trunnion-mounted ball valve.

Ball is held only by seats.

Compact, simple, and cost-effective.

Best for low to medium pressure and smaller sizes.

Ball is anchored by shafts (trunnions) at both ends.

Can handle higher pressures and larger sizes.

More expensive and complex.

Ultimately, the choice depends on application requirements such as pressure, size, and budget.

Floating ball valves are manufactured in compliance with international standards to ensure safety, reliability, and interchangeability. Key standards include:

API 6D / ISO 14313 – Specification for pipeline ball valves.

ASME B16.34 – Pressure-temperature ratings for valves.

API 607 / ISO 10497 – Fire-safe testing for ball valves.

ISO 15848 – Fugitive emissions testing.

Compliance with these standards ensures that floating ball valves can perform reliably even in demanding environments.

With growing industrial demand and environmental regulations, floating ball valves are evolving:

Advanced Materials – Wider use of corrosion-resistant alloys, composites, and polymers.

Automation – Increased adoption of pneumatic and electric actuators for smart process control.

Digital Integration – Smart valves with sensors for monitoring pressure, temperature, and valve position.

Eco-Friendly Design – Focus on reducing fugitive emissions and energy consumption.

As industries push for greater efficiency and sustainability, floating ball valves will continue to play a critical role in modern flow control systems.

Floating ball valves combine simplicity, reliability, and cost-effectiveness in one compact package. By allowing the ball to float slightly under fluid pressure, these valves achieve excellent sealing performance for a wide range of applications. From oil and gas to water treatment, they remain a cornerstone of industrial fluid control.

While they are best suited for small to medium-sized, moderate-pressure systems, ongoing innovations in materials and automation are expanding their capabilities. With the rise of smart valves and digital monitoring, the floating ball valve will remain not only relevant but essential in the future of global industries.