In the complex world of industrial operations, the smallest component can sometimes carry the heaviest responsibility. Safety valves are a perfect example of this principle. Though compact and often overlooked, these devices are the last line of defense against catastrophic accidents caused by excess pressure. Whether in a refinery processing crude oil, a chemical plant manufacturing essential compounds, or a power station generating electricity, safety valves silently ensure that pressure never reaches dangerous levels.

These valves are not optional extras—they are essential safeguards. Without them, industrial facilities would face significantly higher risks of explosions, equipment damage, and even loss of life. Their role is so critical that international standards and engineering codes mandate their use in virtually every system where pressure builds. Understanding how they work not only highlights their importance but also reveals the sophisticated engineering behind their simple appearance.

This article explores in detail how safety valves work, the different types commonly used across industries, and why their design and reliability are central to the safe operation of modern plants.

At its heart, a safety valve is designed to do one thing: protect a system from overpressure.

When pressure inside a vessel, pipeline, or piece of equipment rises beyond a safe threshold, the valve automatically opens. It then releases the excess fluid—whether steam, gas, or liquid—into the atmosphere or into a designated discharge system. By doing this, the valve lowers the internal pressure, bringing it back to a safe level.

Once the system pressure stabilizes, the valve closes again, ensuring normal operation resumes without interruptions. This automatic and repeatable cycle is what makes safety valves indispensable.

Consider the example of a steam boiler. Boilers operate under high pressure, and without a functioning safety valve, even a minor malfunction could lead to an explosion. In fact, history records many early boiler accidents in the 19th century before safety valves became standard equipment. Today, thanks to rigorous engineering, such disasters are rare.

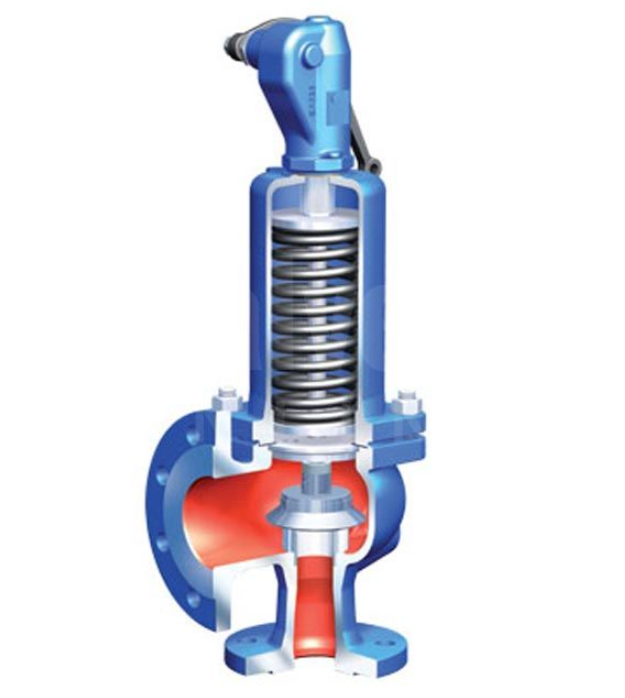

The principle behind a safety valve is straightforward, but the execution is highly precise.

Set Pressure: Each safety valve is designed with a "set pressure," which is the maximum pressure it allows before activating.

Spring or Pilot Mechanism: Most valves rely on a spring or pilot system calibrated to balance the pressure. As long as the system pressure stays below the set point, the valve remains closed.

Activation: When the system pressure exceeds the set point, the force of the fluid overcomes the spring or sealing mechanism. This causes the valve to lift or open.

Discharge: The valve allows excess fluid to escape quickly and safely, reducing pressure inside the equipment.

Reseating: Once pressure returns to normal, the valve reseats itself, ensuring tight closure and preventing leakage.

This elegant balance between restraint and release allows safety valves to function without external power or complicated controls. In many cases, they are the only fail-safe left when all other systems fail.

While all safety valves share the same purpose, their designs vary depending on the application. Broadly, they can be grouped into three main categories:

Spring-loaded safety valves are the most widely used type across industries such as oil and gas, power generation, and petrochemicals.

Mechanism: A spring holds the valve disc in place, keeping the valve closed under normal conditions. When internal pressure exceeds the spring force, the valve opens. Once the pressure drops, the spring pushes the disc back to the closed position.

Advantages:

Simple design and construction

Reliable in most industrial applications

Easy to test and maintain

Applications: Boilers, pressure vessels, chemical reactors, and pipelines frequently rely on this type.

The simplicity of spring-loaded safety valves makes them robust. They do not require external controls and can be calibrated with precision, ensuring they open exactly at the desired set pressure.

Pilot-operated safety valves represent a more sophisticated engineering solution.

Mechanism: These valves use system pressure itself to maintain a tight seal. A small pilot valve senses the pressure and controls the larger main valve. When the system pressure exceeds the set limit, the pilot valve opens, triggering the main valve to release the excess pressure.

Advantages:

Precise control over opening and closing

Suitable for very high-pressure applications

Compact size compared to spring-loaded valves of the same capacity

Applications: Natural gas processing plants, oil refineries, offshore platforms, and other operations where flow capacity is high and accuracy is critical.

POSVs are especially useful in modern high-capacity systems where a standard spring-loaded design would either be too bulky or insufficiently accurate.

Direct-acting safety valves are simpler than both spring-loaded and pilot-operated designs.

Mechanism: System pressure acts directly on the valve disc. When the pressure surpasses the resistance provided by a weight or spring, the valve lifts and releases the excess.

Advantages:

Extremely simple and reliable

Compact design

Minimal maintenance required

Applications: Smaller systems such as air compressors, domestic gas systems, and low-pressure water installations.

Though not suitable for large-scale industrial plants, direct-acting valves are essential in smaller or secondary systems where safety still matters.

Designing and selecting a safety valve requires careful thought. Factors such as system pressure, temperature, the type of medium (gas, steam, or liquid), and discharge requirements must all be considered.

Key aspects include:

Material Selection: Stainless steel, carbon steel, and special alloys are chosen depending on corrosion resistance and operating temperature.

Orifice Size: Determines how much fluid can be discharged during overpressure.

Set Pressure & Blowdown: The valve must open precisely at the set pressure and close only when it is safe. "Blowdown" refers to the difference between the opening and reseating pressures.

Discharge Direction: Valves may vent to the atmosphere or to a closed discharge system, depending on safety and environmental needs.

These design details ensure that each valve performs reliably under real-world conditions.

Power Plants: Boilers, turbines, and steam lines rely heavily on safety valves to prevent dangerous steam explosions.

Oil & Gas: Refineries and offshore rigs operate under high pressures, where safety valves protect against uncontrolled releases of hydrocarbons.

Chemical Industry: Reactors and storage tanks handling volatile chemicals need valves to prevent both pressure accidents and toxic releases.

Pharmaceuticals & Food Processing: Even in non-hazardous industries, valves maintain system integrity and ensure compliance with safety regulations.

Everyday Use: Household water heaters and air compressors are fitted with simple safety valves to protect users.

These diverse applications underscore just how universal and essential these devices are.

A safety valve is only as good as its condition. Regular maintenance is therefore a legal and operational necessity.

Inspection: Visual checks for corrosion, leaks, and physical damage.

Testing: Periodic pressure tests ensure valves open at the correct set point.

Cleaning & Calibration: Removing dirt or deposits and adjusting spring tension maintains performance.

Replacement: Worn-out or damaged valves must be replaced immediately.

Many industrial disasters have been traced back to neglected or malfunctioning safety valves. As such, most international safety standards—such as ASME (American Society of Mechanical Engineers) and API (American Petroleum Institute) codes—mandate regular inspection schedules.

As industries push toward higher efficiency, higher pressures, and more complex systems, the role of safety valves grows even more critical. With the rise of renewable energy, hydrogen production, and advanced chemical processes, demand for precise, reliable, and durable safety valves is only set to increase.

Modern smart technologies are also being integrated into safety systems. Sensors can now monitor valve performance in real time, predicting wear or failure before it occurs. These innovations point to a future where safety valves not only react but also provide valuable data for predictive maintenance.

Safety valves may be small in size, but their role is enormous. They stand as silent guardians, protecting industrial equipment, workers, and the environment from the dangers of overpressure. From the straightforward spring-loaded design to advanced pilot-operated systems, each type of valve has its place in the vast landscape of industrial applications.

Their reliable performance, backed by rigorous maintenance and adherence to international standards, ensures that industries can operate safely even under the most demanding conditions. As technology advances, safety valves will continue to evolve—becoming smarter, more efficient, and even more indispensable.

In the end, when pressure mounts—literally—it is the humble safety valve that ensures disaster is averted.