Stainless steel globe valves are essential components in fluid control systems, designed to regulate and throttle the flow of liquids, gases, and steam. Their precise control capabilities make them a preferred choice in industries where accurate flow regulation and tight shutoff are necessary. These valves are widely used in applications ranging from water treatment and chemical processing to oil and gas pipelines and power generation.

Unlike gate valves, which primarily function as on-off valves, stainless steel globe valves offer superior throttling capabilities. Their robust construction, high corrosion resistance, and ability to withstand extreme temperatures and pressures make them an ideal solution for demanding industrial environments.

This article provides an in-depth exploration of stainless steel globe valves, covering their types, construction, working principles, advantages, applications, and maintenance requirements.

Stainless steel globe valves are available in various designs, each tailored to specific operational needs. The four primary types are:

Standard globe valves are the most commonly used type, featuring a straight-through body design with an internal baffle that directs fluid flow. They provide effective flow regulation and tight shutoff, making them suitable for general-purpose applications such as water distribution, steam control, and chemical processing.

Key Features:

Moderate pressure drop due to internal flow path

Reliable sealing performance

Commonly used in medium to high-pressure applications

Applications:

Water treatment facilities

Industrial steam systems

General fluid control in processing industries

Angle globe valves are designed with a 90-degree turn between the inlet and outlet, reducing the need for additional pipe fittings. This configuration minimizes pressure drop and turbulence, making them ideal for applications where space constraints or directional flow changes are required.

Key Features:

Fewer pipe fittings needed, reducing installation costs

Suitable for applications where flow direction changes are necessary

Lower pressure drop compared to standard globe valves

Applications:

Cooling water systems

Pump discharge systems

High-pressure steam control

Y-pattern globe valves feature a stem and seat that are angled at approximately 45 degrees, reducing flow resistance and pressure drop compared to standard globe valves. These valves are commonly used in high-pressure and high-temperature applications, where efficiency and durability are crucial.

Key Features:

Reduced pressure drop for improved flow efficiency

Longer service life due to lower erosion and wear

Ideal for continuous throttling applications

Applications:

High-pressure steam pipelines

Petrochemical industries

Power plants and boiler feedwater systems

Three-way globe valves are used for mixing or diverting fluid flow between three different ports. They are often found in HVAC systems, industrial mixing applications, and automated process control.

Key Features:

Capable of mixing or diverting fluid streams

Offers precise control over flow direction and temperature regulation

Suitable for automated control systems with actuators

Applications:

Industrial heating and cooling systems

Chemical blending and process control

Fuel and lubricant distribution networks

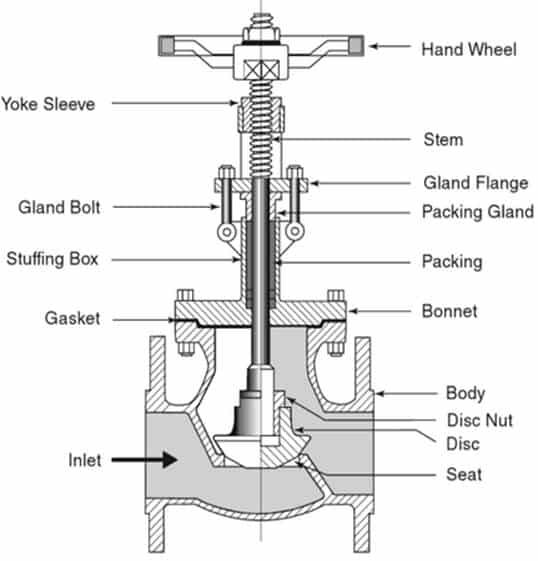

A stainless steel globe valve is built with several key components that work together to regulate fluid flow effectively. Each part is designed to ensure durability, tight sealing, and resistance to wear and corrosion.

The body is the primary housing of the valve and is typically made of stainless steel grades such as 304, 316, or 316L, which offer excellent corrosion resistance and mechanical strength.

The bonnet is a cover that encloses the valve’s internal components and is bolted or welded to the body for secure operation. It provides access to the internal parts for maintenance and repair.

The disc is the movable element that controls the flow of fluid. It moves up and down to open or close the valve. Depending on the application, it can be made of hardened stainless steel, tungsten carbide, or other wear-resistant materials.

The seat provides a sealing surface for the disc to rest against when the valve is closed. It is typically made of stainless steel or a hard alloy to resist erosion and corrosion.

The stem connects the actuator or handwheel to the disc, transmitting motion to open or close the valve. High-quality stainless steel stems are used to ensure strength and resistance to mechanical stress.

The packing, usually made of PTFE, graphite, or other sealing materials, prevents fluid leakage around the stem. The gland compresses the packing material to create a tight seal.

Manual globe valves use a handwheel, while automated valves may have pneumatic, electric, or hydraulic actuators for precise control.

The operation of a stainless steel globe valve is based on the movement of the stem and disc to regulate fluid flow. The valve functions as follows:

Closing the Valve: When the handwheel or actuator is turned clockwise, the stem moves downward, pressing the disc against the seat, blocking fluid flow.

Opening the Valve: When the handwheel or actuator is turned counterclockwise, the stem lifts the disc, allowing fluid to pass through.

Throttling the Flow: By adjusting the degree to which the disc is lifted, the valve can control the flow rate with high precision.

Globe valves are designed to handle frequent throttling operations, making them ideal for flow control applications where gradual adjustments are required.

Stainless steel globe valves offer numerous benefits, making them one of the most reliable choices for industrial fluid control.

Corrosion Resistance: Stainless steel construction ensures long-term resistance to rust, corrosion, and chemical exposure.

Durability: High mechanical strength allows these valves to operate under extreme pressures and temperatures.

Precise Flow Control: Unlike gate valves, globe valves provide superior throttling and fine-tuned flow regulation.

Leak Prevention: The tight sealing mechanism minimizes leakage, enhancing system safety and efficiency.

Versatility: Suitable for handling a wide range of fluids, including water, oil, gas, chemicals, and steam.

Used in potable water systems, wastewater treatment, and desalination plants.

Controls water pressure and distribution efficiently.

Regulates the flow of aggressive chemicals and high-temperature fluids.

Stainless steel construction prevents corrosion from acidic or caustic substances.

Employed in crude oil and natural gas pipelines.

Provides reliable shutoff in refineries and offshore drilling operations.

Found in steam turbines, boiler feedwater systems, and cooling circuits.

Y-pattern globe valves are commonly used for high-pressure steam applications.

Regulates water, refrigerant, and air in heating and cooling networks.

Three-way globe valves help in mixing hot and cold water for temperature control.

To ensure optimal performance, regular maintenance is required:

Inspection: Check for leaks, corrosion, and wear on sealing components.

Lubrication: Keep the stem and actuator well-lubricated for smooth operation.

Cleaning: Remove debris or buildup that could affect valve performance.

Seal Replacement: Replace worn-out seats and packing materials to prevent leaks.

Stainless steel globe valves are essential in industrial applications where precise flow control, durability, and corrosion resistance are required. Their versatility makes them suitable for use in water treatment, chemical processing, oil and gas, power plants, and HVAC systems. With proper selection, installation, and maintenance, these valves ensure reliable and efficient operation, contributing to the overall safety and performance of fluid control systems.