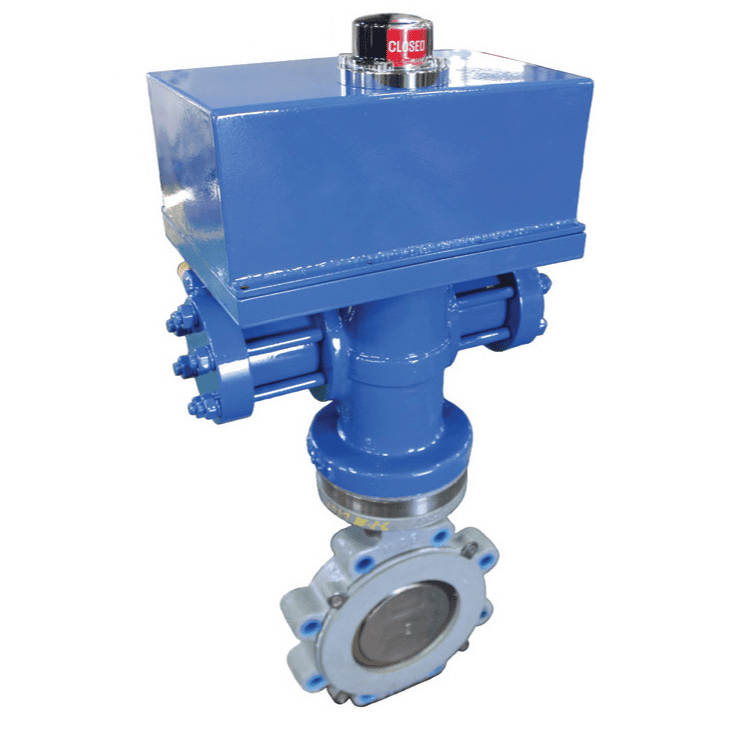

In industrial automation and fluid control systems, actuators play a crucial role in regulating valve operations. Among the various types available, electro-hydraulic actuators stand out for their efficiency, power, and versatility. These devices combine the precision of electric actuators with the high-force capabilities of hydraulic systems, making them ideal for demanding applications.

Unlike traditional hydraulic systems that rely on external power units, electro-hydraulic actuators are self-contained, integrating both electrical and hydraulic components into a single unit. This design simplifies installation, reduces maintenance, and enhances reliability—key factors in industries where downtime is costly.

This article explores the working principles, advantages, and applications of electro-hydraulic actuators, highlighting why they are increasingly becoming the preferred choice for modern industrial systems.

Electro-hydraulic actuators operate by converting electrical energy into hydraulic power to control valve movement. The process involves several key components:

Electric Motor – The system begins with an electric motor that drives a hydraulic pump.

Hydraulic Pump – The pump pressurizes hydraulic fluid, creating the force needed for actuation.

Hydraulic Actuator – The pressurized fluid moves a piston or rotary mechanism, which then operates the valve.

Control System – Advanced models include programmable logic controllers (PLCs) or smart sensors for precise adjustments in speed, force, and position.

Since the entire system is self-contained, there is no need for external hydraulic power units (HPUs), reducing complexity and potential leak points. This makes electro-hydraulic actuators more compact, efficient, and easier to install compared to traditional hydraulic setups.

Electro-hydraulic actuators deliver exceptional force in a compact design, capable of handling loads up to 4,800 pounds. This makes them suitable for heavy-duty applications where pneumatic or electric actuators fall short.

Unlike purely hydraulic systems, electro-hydraulic actuators offer fine-tuned control over valve positioning. Engineers can adjust:

Stroke length

Operating speed

Applied force

Fail-safe modes

This level of precision is essential in industries like oil & gas, water treatment, and power generation, where exact valve positioning is critical.

Traditional hydraulic systems require frequent maintenance due to fluid leaks, pump wear, and external piping issues. Electro-hydraulic actuators, however, are sealed units, minimizing leakage risks and reducing upkeep. Additionally, their self-contained nature eliminates the need for external HPUs, further boosting reliability.

Hydraulic systems are notoriously loud due to pump noise and fluid turbulence. Electro-hydraulic actuators, in contrast, operate much more quietly, making them ideal for noise-sensitive environments like urban water plants or indoor industrial facilities.

Since these actuators do not rely on external hydraulic power sources, they can be installed in remote or confined spaces without compromising performance. This flexibility allows engineers to design more efficient and space-saving systems.

Modern electro-hydraulic actuators can be integrated into Industrial IoT (IIoT) systems, enabling:

Remote monitoring

Predictive maintenance alerts

Real-time diagnostics

Automated adjustments via PLCs

This connectivity enhances operational efficiency and reduces unexpected downtime.

Thanks to their power, precision, and adaptability, electro-hydraulic actuators are used across multiple industries:

Pipeline valve control

Blowout preventers (BOPs)

Refinery process valves

Large gate and butterfly valves

Flow control in pumping stations

Emergency shut-off systems

Steam turbine control

Cooling system valves

Nuclear plant safety mechanisms

Press machines

Robotic automation

Material handling systems

Ballast control systems

Ship engine valve regulation

Subsea equipment

While traditional hydraulic actuators have been the industry standard for decades, electro-hydraulic alternatives offer several improvements:

|

Feature |

Electro-Hydraulic Actuators |

Traditional Hydraulic Actuators |

|

Power Source |

Self-contained (electric + hydraulic) |

Requires external HPU |

|

Maintenance |

Low (sealed system) |

High (leaks, pump wear) |

|

Noise Levels |

Quiet |

Loud |

|

Precision Control |

High (programmable) |

Limited |

|

Installation |

Flexibility Can be placed anywhere |

Needs proximity to HPU |

|

Smart Capabilities |

IoT-compatible |

Typically manual |

Electro-hydraulic actuators represent a technological leap in valve control systems, combining the best aspects of electric and hydraulic power. Their self-contained design, high force output, precision control, and smart capabilities make them indispensable in modern industrial applications.

As industries continue to prioritize automation, energy efficiency, and reliability, electro-hydraulic actuators will play an increasingly vital role. Engineers and system designers now have a powerful, flexible, and low-maintenance solution that outperforms traditional hydraulic systems in nearly every aspect.

For businesses looking to upgrade their valve control mechanisms, investing in electro-hydraulic actuators is not just an improvement—it’s a strategic advantage.

The shift toward smarter, more efficient industrial systems is accelerating, and electro-hydraulic actuators are at the forefront of this transformation. With their ability to deliver high power, precision, and connectivity, they are setting new standards in fluid control technology.

Whether in oil & gas, water treatment, or heavy manufacturing, these actuators are proving to be the future of industrial valve automation.