Slab Gate Valves, also known as Through Conduit Gate Valves, play a critical role in the safe and efficient transportation of fluids such as natural gas, crude oil, and refined oil products. These valves are engineered to provide reliable flow control in pipelines, ensuring both operational efficiency and safety under demanding conditions. The unique design of slab gate valves allows them to operate seamlessly in high-pressure, high-temperature applications, making them a preferred choice for industrial pipelines worldwide.

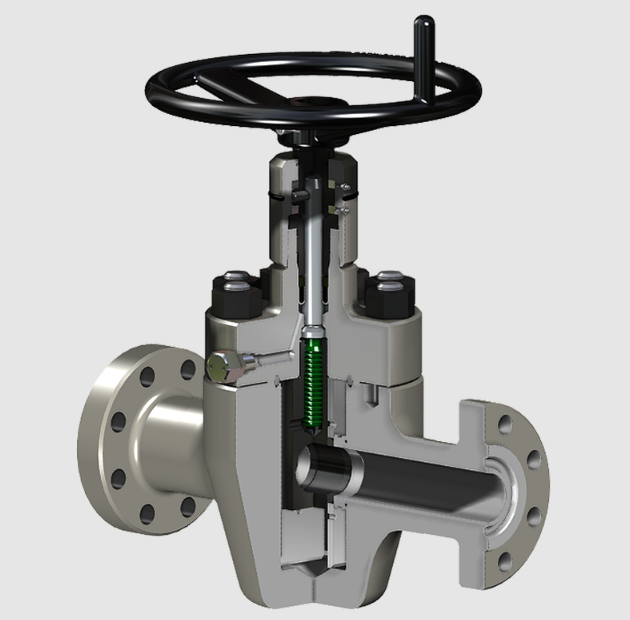

Unlike conventional gate valves, the slab gate valve features a solid rectangular gate, often referred to as a slab, that moves vertically inside the valve body. This movement enables precise flow control and reliable sealing, even in systems where the pipeline medium is abrasive or corrosive. The valve's design also allows it to handle emergency scenarios effectively, supporting fail-safe operations through mechanical and hydraulic interactions.

In this article, we will explore the operational principles, structural features, sealing mechanisms, and industrial applications of slab gate valves. By understanding these aspects, engineers, operators, and decision-makers can make informed choices for their pipeline projects.

The operation of a slab gate valve is both straightforward and highly efficient. At its core, the valve consists of a solid metal gate that moves vertically within the valve body to control the flow of fluids.

When the valve is open, the gate is fully retracted, allowing the medium to flow freely through the pipeline. This design minimizes flow resistance and ensures a smooth passage of liquids or gases, reducing pressure loss and improving system efficiency. When closed, the gate descends between two robust seat rings, creating a secure seal that prevents leakage.

A key advantage of slab gate valves is their ability to operate effectively under high-pressure and high-temperature conditions. The precision of the vertical movement ensures consistent contact between the gate and the seat rings, which is critical for achieving a leak-proof seal. For visual representation, slab gate valve drawings and animations often show a rectangular metal plate moving within a cylindrical body, highlighting the simplicity and effectiveness of the mechanism.

This vertical motion, combined with the hydraulic forces generated by the medium inside the valve, makes slab gate valves ideal for emergency situations. In certain designs, the pressure of the fluid itself can assist the actuator spring, helping the valve automatically move to a safe fail-open or fail-closed position during system malfunctions.

Slab gate valves can be configured for standard or reverse operation, depending on system requirements:

In this configuration, the valve is closed when the valve stem is in the down position. This design is commonly used for fail-open applications, as the upward force from fluid pressure helps the actuator spring to lift the gate when opening the valve. This setup is ideal for scenarios where maintaining flow in the event of a system failure is critical.

Here, the valve is closed with the valve stem in the up position. This design supports fail-closed configurations because the fluid pressure aids the actuator spring in pressing the gate down into the closed position. Such a design is essential when preventing fluid flow during emergencies is a top priority.

Both configurations leverage the unique interaction between fluid pressure and mechanical springs, enhancing the valve’s reliability and safety in high-risk applications.

A standout feature of slab gate valves is their spring-loaded floating seats, which provide positive sealing regardless of upstream or downstream pressure. The seats are engineered to respond dynamically to system pressures, ensuring reliable closure under all conditions:

Low Pressure: The spring mechanism energizes the seat, maintaining tight contact with the gate to prevent leakage.

High Pressure: As the line pressure rises, it enhances the contact force between the seat and the gate, creating a positive seal that becomes stronger under higher operational pressures.

The two seats operate independently, energized by the pressure differential across each seat. This design allows the valve cavity to be vented safely when the upstream or downstream sides are pressurized. Such a configuration ensures consistent sealing performance while enabling maintenance and safety procedures without disrupting pipeline operations.

Slab gate valves are engineered for durability, reliability, and low-maintenance operation. Key structural features include:

The seats are equipped with O-ring seals and a floating design with preload, which provides bidirectional sealing. This design reduces operating torque, allowing the valve to open and close smoothly, even under high-pressure conditions.

The sealing surfaces of the valve seat are often inlaid or surfaced with stainless steel or cobalt-chromium-tungsten alloys, offering a combination of metal-to-metal and soft sealing. This dual sealing mechanism enhances leak resistance and allows debris to be expelled from the sealing area during operation.

Valves with metal-to-metal sealing can be equipped with an external grease injection system, which lubricates the contact surfaces to achieve zero leakage. This feature extends service life and ensures reliable sealing in long-term operation.

The gate (wedge) often includes diversion holes that prevent the medium from scouring the sealing surface. This ensures consistent sealing whether the valve is fully open or fully closed, prolonging service life and maintaining performance.

When fully open, slab gate valves provide a smooth, unobstructed channel. This minimizes flow resistance and pressure loss, making the valves highly efficient. Some designs incorporate a ball top or similar feature to clean the pipeline during operation, maintaining system integrity.

The valve stem and packing are designed for minimal friction, reducing wear and leakage. The packing requires little adjustment, allowing for convenient operation and reliable sealing over long periods.

Upon closure, the valve can automatically release pressure from the internal chamber, enhancing safety and preventing overpressure damage.

Slab gate valves feature a fully enclosed design, providing excellent protection against environmental conditions, including extreme weather. This ensures operational reliability in outdoor or industrial environments.

Valves are often equipped with indicator rods or observation windows to provide visual confirmation of the valve’s open or closed status. This facilitates monitoring and maintenance in large pipeline systems.

The design and construction of slab gate valves provide several operational advantages:

High Reliability: The combination of floating seats, spring-loaded mechanisms, and metal-to-metal sealing ensures minimal leakage and consistent performance.

Safety in Emergencies: The interaction between fluid pressure and actuator springs allows the valve to automatically move to a safe position in the event of system failure.

Bidirectional Sealing: The floating seat design and O-ring preloading allow sealing in both directions, accommodating variable pressure scenarios.

Low Maintenance: Grease injection systems and durable sealing surfaces reduce the need for frequent servicing, minimizing downtime.

Efficient Flow Control: The fully open valve provides minimal flow resistance, reducing energy loss and pressure drop in pipelines.

Adaptability: Slab gate valves are suitable for high-pressure, high-temperature, and corrosive media applications, making them versatile for oil, gas, and chemical industries.

Slab gate valves are widely used across multiple sectors, particularly where reliability and safety are paramount:

Oil and Gas Pipelines: Slab gate valves are ideal for crude oil, natural gas, and refined product pipelines due to their ability to handle high pressure and temperature fluctuations.

Chemical Industry: The valves’ durable sealing surfaces and corrosion-resistant materials make them suitable for handling aggressive chemicals.

Power Plants: Slab gate valves are used in steam lines, cooling water systems, and fuel transport lines, where reliable flow control is critical.

Water and Wastewater Systems: Bidirectional sealing and low maintenance make these valves suitable for municipal and industrial water systems.

The ability to maintain a tight seal under extreme conditions, combined with low friction and minimal maintenance requirements, ensures that slab gate valves continue to be a preferred choice for critical pipeline operations.

While slab gate valves are designed for durability, proper operation and maintenance are essential for maximizing service life:

Regular Inspection: Routine checks of seat integrity, packing, and actuator mechanisms help prevent unexpected failures.

Lubrication: Valves with grease injection systems should be periodically lubricated to maintain zero-leakage performance.

Operating Torque Monitoring: Ensuring the opening and closing torque remains within recommended limits prevents undue wear on the valve components.

Cleaning: For pipelines carrying abrasive media, periodic cleaning of the wedge and sealing surfaces prevents debris accumulation and maintains effective sealing.

By adhering to these maintenance practices, operators can ensure reliable operation, reduce downtime, and extend the lifespan of slab gate valves.

Slab gate valves are a cornerstone of modern pipeline technology, offering robust, reliable, and safe flow control for high-pressure and high-temperature applications. Their combination of floating seats, spring-loaded mechanisms, and metal-to-metal sealing provides unparalleled performance in oil, gas, chemical, and water pipelines.

The versatility of slab gate valves, including their ability to operate in fail-open or fail-closed configurations, makes them an indispensable component for industrial pipelines worldwide. With proper maintenance and operation, these valves provide long-term reliability, efficiency, and safety, ensuring smooth operation across demanding industrial applications.

Whether transporting crude oil across vast pipeline networks, controlling flow in chemical processing plants, or managing high-pressure water lines, slab gate valves deliver consistent performance, leak-proof sealing, and low-maintenance operation, reinforcing their reputation as an essential solution in modern industrial fluid management systems.