Abstract: In chemical environments, butterfly valves are highly susceptible to corrosion due to prolonged exposure to aggressive media, which can lead to leakage, production interruptions, and safety risks. This article examines the corrosion and failure mechanisms of butterfly valves, emphasizing that electrochemical corrosion is the primary cause and localized corrosion is the predominant form. Based on practical case studies, this article highlights the synergistic effects of material defects and operating conditions in accelerating corrosion. Furthermore, this article systematically reviews recent progress in materials, surface treatment methods, and composite modification technologies applied to corrosion-resistant butterfly valves. Regarding material selection, metallic materials such as stainless steel and nickel-based alloys, as well as non-metallic materials such as fluoroplastics and carbon fiber composites, are used in different application scenarios according to their performance characteristics. From a manufacturing standpoint, surface treatments and material composite modification techniques can significantly improve corrosion resistance.

In chemical production, pipeline valves are frequently exposed to highly corrosive media such as acids, alkalis, and high-temperature flue gases. Corrosion may result in leaks, production interruptions, and even serious safety hazards. Butterfly valves, valued for their compact design, low flow resistance, and quick operation, are used in approximately 40% of chemical pipeline applications. However, conventional butterfly valves face serious challenges in corrosive environments. For instance, in a copper refinery’s flue gas acid production unit, severe corrosion occurred within two to three months due to electrolytic corrosion combined with casting defects. Under the “dual carbon” strategy, emerging industries such as nuclear power and advanced materials are driving a growing demand for high-reliability valves. Although China leads the world in valve production by volume, high-end valves for extreme conditions—such as ultra-high temperatures, ultra-high pressures, and high-frequency operations—remain largely dependent on imports, which account for over 70% of the market. This article provides a systematic analysis of technological advancements in corrosion-resistant butterfly valves, emphasizing corrosion mechanisms, material development, and manufacturing technologies. It also addresses current industry challenges and proposes targeted development strategies, offering guidance to improve the reliability of chemical process equipment and drive technological advancement in the valve industry.

Corrosion in chemical environments is primarily electrochemical. The process medium usually acts as an electrolyte, forming a galvanic cell that drives the dissolution of the metal anode. The corrosion rate is affected by factors such as pH, temperature, pressure, and chloride ion concentration. Additionally, high-velocity fluid flow can disrupt protective corrosion films, further accelerating the corrosion process. Under the combined influence of electrochemical corrosion and environmental factors, corrosion in chemical environments often manifests as localized damage, which is particularly severe. Localized corrosion is more destructive than uniform corrosion and can take several forms:

Pitting corrosion: Occurs when the passivation film is damaged, resulting in the formation of localized pits.

Crevice corrosion: Occurs when corrosive media are trapped in connection gaps, forming concentration cells.

Intergranular corrosion: Develops due to the sensitization of stainless steel, leading to chromium depletion along grain boundaries.

Stress corrosion cracking (SCC): Results from the combined effects of tensile stress and exposure to specific corrosive media.

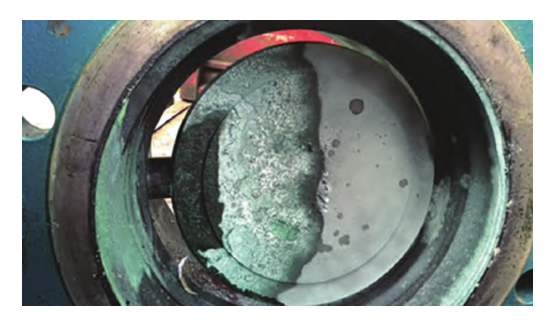

Jia Yougen et al. analyzed the corrosion of butterfly plates in seawater butterfly valves used in nuclear power plants and concluded that the primary causes were casting defects in the plates, pitting from seawater chloride ions, and electrochemical corrosion between the titanium tubes and the butterfly plates in the heat exchanger. In a copper smelting flue gas acid-production unit, the medium in contact with the butterfly valve consists of 98% concentrated sulfuric acid, with temperatures fluctuating around 110 °C. Severe corrosion developed within 2–3 months, as shown in Figure 1. Failure analysis indicated that localized perforation primarily originated from casting defects, such as shrinkage cavities and inclusions, which served as active corrosion sites. In contrast, uniform corrosion is largely associated with electrolytic corrosion caused by the anodic protection system, where metal dissolution rates can increase more than tenfold due to potential differences. Failures of butterfly valves are closely linked to the properties of individual components and the corresponding corrosion mechanisms. Specifically:

Valve body: Its structural design makes it susceptible to general corrosion, which can cause wall thinning.

Flange gaps and welds: Connection points are prone to intergranular corrosion, potentially leading to leaks.

Flow passages: High-velocity media can cause erosion and even perforation.

Disc edge: Its structural design results in sudden increases in flow velocity, making it susceptible to both erosion and pitting corrosion, as well as stress corrosion cracking caused by stress concentration.

Valve stem: Crevice structures form localized electrochemical environments, increasing the risk of corrosion-induced fractures.

Seals: Their material properties make them prone to swelling, aging, or failure due to particle wear.

Figure 1. Macroscopic appearance of corrosion products on the surface of an acid-resistant butterfly valve

To address the issues described above, corrosion prevention measures must be closely aligned with the properties of the process media. Effective corrosion resistance requires careful material selection and optimization of component design and properties. Structural designs should minimize damage resulting from crack formation and erosion caused by the process media. Assembly stresses should be controlled to prevent stress-accelerated corrosion, and regular maintenance—including timely replacement of aging components—should be carried out to break the corrosion chain formed by the interaction of corrosion mechanisms and component properties. Table 1 summarizes the typical failure modes and mechanisms of various chemical butterfly valves. Notably, gas shut-off butterfly valve 78 is particularly prone to stress corrosion cracking when exposed to hydrogen- and sulfur-containing media. Cavitation pits on the disc surface, formed under high-pressure differential throttling conditions, facilitate the adsorption of hydrogen and sulfur, allowing hydrogen atoms to penetrate the metal grain boundaries and rapidly propagate cracks. This type of failure occurs suddenly and is difficult to detect using conventional testing or early warning methods.

Table 1 Typical Failure Modes and Mechanisms of Chemical Butterfly Valves

|

Working Environment |

Failure Form |

Dominant Mechanism |

Typical Cases |

|

Flue gas acid production |

Valve body perforation |

Electrolytic corrosion + casting defects |

Failure within 2–3 months in copper smelters |

|

Nuclear power seawater |

Sealing surface failure |

Erosion corrosion + pitting corrosion |

Circulating water system leakage |

|

Acetic acid system |

Valve stem fracture |

Corrosion fatigue |

PTA device vibration fracture |

|

Gas shut-off |

Valve plate erosion |

H-S stress corrosion |

Gas purification system |

(1) Stainless Steel

Stainless steel is one of the most widely used metals in butterfly valve manufacturing because of its excellent corrosion resistance and mechanical properties. In chemical pipelines, commonly used stainless steels include 316L, 304L, and duplex stainless steel. 316L stainless steel is commonly used in butterfly valves due to its excellent corrosion resistance and machinability. In high-temperature, highly corrosive environments, employing 316L stainless steel as the sealing material—together with a special butyl-intercalated graphite surface treatment—significantly improves the valve’s high-temperature performance, corrosion resistance, and service life. Duplex stainless steel, a high-performance material, has increasingly been used in butterfly valves in recent years. Compared with traditional austenitic stainless steel, duplex steel provides higher mechanical strength and enhanced resistance to chloride-induced corrosion. Chen Meng et al. investigated the galvanic corrosion between duplex stainless steel and aluminum bronze at various area ratios. As shown in Table 2, once the galvanic couple was formed, the corrosion rate of aluminum bronze increased, with the anodic corrosion rate rising as the area ratio increased. The coupling current does not strongly correlate with the self-corrosion potential difference of the galvanic metals; rather, it is influenced by the polarization state of the electrodes during coupling. In seawater pump outlet pipelines, duplex stainless steel exhibits markedly superior corrosion resistance compared to aluminum bronze, thereby extending the service life of butterfly valves and making it especially suitable for seawater and chemical applications.

Table 2 Galvanic Corrosion Data at Different Area Ratios

|

Galvanic Couple |

Corrosion Rate at 5:1 |

Corrosion Rate at 1:1 |

Rate Increase at 5:1 |

|

Duplex Steel/Aluminum Bronze |

28.89/930.87 |

33.45/511.78 |

-16.5/110.35% |

Additionally, sintered stainless steel technology provides a novel approach to enhancing the performance of butterfly valve materials. Research shows that sintering 304L stainless steel with molybdenum powder creates Mo-rich regions within the material. After high-temperature heat treatment, these Mo-rich regions effectively inhibit the initiation and propagation of pitting corrosion, thereby improving the material’s overall corrosion resistance.

(2) Nickel-Based and Specialty Alloys

In highly corrosive environments, conventional stainless steels and copper-based alloys may not provide adequate performance, making the use of nickel-based or other specialty alloys necessary. Nickel-based alloys offer excellent corrosion resistance and high-temperature performance, making them well-suited for applications involving strong acids, strong alkalis, and elevated temperatures. Table 3 compares the properties of various metal materials. Titanium alloys, duplex stainless steel, and Monel demonstrate excellent corrosion resistance. Carbon steel performs poorly in all aspects except cost, whereas nickel-based alloys offer excellent corrosion and wear resistance.

Table 3 Comparison of Metal Material Properties

|

Material |

Corrosion Resistance |

Wear Resistance |

Economy |

Comprehensive Performance |

|

Aluminum Bronze |

Good |

Poor |

Acceptable |

— |

|

316 / 316L Stainless Steel |

General |

Good |

— |

— |

|

Carbon Steel |

Poor |

Poor |

— |

— |

|

10CrMoAl |

Acceptable |

Acceptable |

— |

— |

|

H1250 / Ni2 |

Good |

Acceptable |

Poor |

Good |

|

Duplex Steel |

Excellent |

Excellent |

Excellent |

— |

|

0Cr17Ni4Cu4Nb |

Good |

Excellent |

— |

— |

|

Titanium Alloy |

Excellent |

— |

— |

— |

|

Monel |

Excellent |

— |

— |

— |

Controlled-composition cast steel is the preferred material for seawater butterfly valves at the Chengli Nuclear Power Plant. For instance, controlled nickel-chromium WCB cast steel offers improved corrosion resistance while retaining the machinability of carbon steel, achieved through precise control of nickel and chromium content. Experiments showed that in a simulated seawater environment, this material’s corrosion rate is comparable to that of nickel-chromium ductile iron, while its mechanical properties are markedly superior and its cost is lower. In 2022, this technical solution was approved by the China General Machinery Industry Association and subsequently implemented in the circulating water system of the Hualong One nuclear power plant. Stellite, a widely used hard alloy with outstanding wear, corrosion, high-temperature, and oxidation resistance, is also employed in butterfly valve manufacturing. Ma Hui et al. found that overlay welding with Stellite can enhance the corrosion and wear resistance of butterfly valve sealing surfaces. However, this alloy is difficult to weld, highly hard, and challenging to process, often leading to rework or repair issues during production. To further enhance corrosion resistance, researchers have developed several new alloy materials. Dai Fan et al. developed 1Cr11Ni2W2MoV steel, and by adding trace amounts of Cu and Sn, they produced a butterfly valve disc material with superior overall performance and corrosion resistance. Copper improves corrosion resistance and machinability, while tin enhances both strength and corrosion resistance. Specific data are provided in Table 4.

Table 4 Material Processing Properties

|

Steel Grade |

Maximum Cutting Force (N) |

Tool Tip Wear (mm) |

|

1Cr11Ni2W2MoV |

1598 |

1.1 |

|

1Cr11Ni2W2MoV + Cu |

1486 |

0.2 |

|

1Cr11Ni2W2MoV + Sn |

1675 |

1.6 |

Butterfly valve materials also include polymers and composites, as summarized in Table 5. Among polymers, fluoroplastics such as PTFE and PFA are widely used for linings and sealing components due to their outstanding corrosion resistance. Polypropylene (PP) and polyethylene (PE) are well-suited for medium- and low-pressure butterfly valves due to their cost-effectiveness and corrosion resistance. PP, in particular, is widely used in medium- and low-pressure valves, whereas PTFE provides superior strength and chemical inertness. Polyetheretherketone (PEEK) is appropriate for high-temperature applications. All-plastic butterfly valves have experienced rapid growth in recent years, with PP and other advanced materials increasingly adopted. Rubbers and elastomers, such as nitrile rubber (NBR) and ethylene propylene diene monomer (EPDM), are widely used as sealing materials because of their versatility across diverse operating conditions. For composite materials, metal-based composites can be reinforced with protective coatings to enhance corrosion resistance, while ceramic-based composites offer excellent high-temperature corrosion resistance and perform reliably in harsh operating conditions.

Table 5: Performance Characteristics and Advantages of Non-Metallic Materials

|

Material |

Performance Characteristics |

Applications / Advantages |

|

Polytetrafluoroethylene (PTFE) |

Excellent corrosion resistance, low friction coefficient, high-temperature stability, chemically inert to nearly all media |

Widely used for linings and sealing components in butterfly valves for chemical, pharmaceutical, and food industries |

|

Perfluoroalkoxy (PFA) |

Comparable corrosion resistance to PTFE, improved processability, superior high-temperature stability |

PFA-coated stainless steel for integrated valve discs and shafts; suitable for high-temperature applications |

|

Polypropylene (PP) and other advanced polymers |

Excellent rigidity, toughness, elasticity, wear resistance, and corrosion resistance; non-toxic and environmentally friendly; leak-proof |

Replacing imported or stainless-steel butterfly valves in sulfuric acid, fertilizer, and pesticide industries; suitable for harsh chemical environments |

|

Nitrile Rubber (NBR) |

Excellent oil and chemical resistance, high airtightness, cold resistance |

Used as sealing and lining materials in butterfly valves |

|

Carbon Fiber Reinforced Plastic (CFRP) |

High strength and modulus, improved high-temperature resistance |

Limited applications in aerospace and high-end chemical industries; suitable for general chemical pipelines |

|

Cermets (e.g., ZSM-5 zeolite coating) |

Excellent corrosion resistance to various acids (≤60°C); economical and environmentally friendly |

Coatings on low-carbon steel substrates; replace toxic or carcinogenic materials, significantly reducing cost |

For corrosion protection of large butterfly valves, organic coatings such as epoxy resins and polyurethanes have demonstrated excellent practical applicability. Their performance characteristics are well suited to the treatment requirements of large-scale equipment. Firstly, these coatings typically cure at ambient temperature, eliminating the need for complex high-temperature equipment and enabling application in confined spaces such as pipelines and valve chambers. Secondly, the coatings can be applied by brushing, rolling, or airless spraying, providing uniform coverage over the complex curves and irregular shapes of large butterfly valves. Additionally, these coatings are flexible, allowing the valve to deform slightly during operation and preventing cracking caused by mechanical stress. Metal coatings—applied through electroplating, thermal spraying, or laser cladding—can greatly improve corrosion and wear resistance. Sun Chunrong et al. evaluated the performance of 24-day brown corundum sandblasted products from three different manufacturers. As shown in Table 6, after 90 days of seawater immersion, no rust propagation was observed along the scribed lines, demonstrating the effectiveness of coating technologies in preventing corrosion during the design, manufacture, and maintenance of seawater butterfly valves. Lining technologies employ internal linings made of corrosion-resistant materials. Rubber linings provide excellent elasticity and sealing performance but have limited resistance to highly corrosive media. Fluoroplastic linings, such as PTFE, are widely used for their excellent chemical inertness, while ceramic linings offer significant advantages in highly corrosive and abrasive environments. Chen Zhongli proposed a fully ceramic-lined butterfly valve that effectively mitigates both corrosion and erosion. The optimized valve design also addresses operational issues, such as restricted opening and closing caused by large particles and damage to the sealing surface.

Table 6: Rust Propagation at the Scribe after Seawater Immersion Test

|

Test Product |

90-Day Immersion Status |

|

Product 1 |

No rust propagation at the coating |

|

Product 2 |

No rust propagation at the coating |

|

Product 3 |

No rust propagation at the coating |

Chemical conversion coating technology forms a strongly bonded, functional protective film on metal surfaces through chemical or electrochemical reactions. Core techniques include phosphating, passivation, and anodizing. Phosphating is applicable to metals such as steel, zinc, and aluminum, in which the metal reacts with an acidic solution containing dihydrogen phosphate to form a crystalline phosphate layer. Its porous structure improves both corrosion resistance and paint adhesion, making it widely used for automotive paint pretreatment and rust protection of mechanical components. Passivation is primarily applied to stainless steel. Strong oxidants, such as nitric acid, are used to promote the formation of a denser Cr₂O₃ layer on the surface. This passivation layer fills the pores of the natural oxide film, significantly enhancing resistance to pitting and crevice corrosion. It is commonly used in medical devices and food processing equipment. Anodizing, applied to aluminum and its alloys, electrolytically forms a porous Al₂O₃ layer. After sealing, the layer’s corrosion and wear resistance are greatly enhanced, and it can be dyed for decorative purposes. This makes it suitable for applications such as architectural profiles and enclosures for electronic equipment. Surface treatment technologies for butterfly valves provide significant benefits, including enhanced corrosion and wear resistance, improved appearance, and strengthened sealing performance. However, they also have limitations, including the high cost of specialized coatings, complex processes requiring dedicated equipment, limited resistance to heat and impact, and the risk of coating delamination. Moreover, processes like electroplating can pose environmental risks.

Alloying is a fundamental method for enhancing the corrosion resistance of metals. Introducing alloying elements into the base metal modifies its structure and chemical properties, thereby improving corrosion resistance. For example, adding chromium (Cr), nickel (Ni), and molybdenum (Mo) to stainless steel promotes the formation of a stable passivation film, enhancing both corrosion and oxidation resistance. Nie Dawei and colleagues added nickel (Ni) and chromium (Cr) to molten iron during spheroidization and inoculation, producing low-NiGr corrosion-resistant ductile iron with excellent properties and a corrosion rate of just 0.065 mm/a. Similarly, adding molybdenum (Mo) to 316L stainless steel significantly improves its resistance to pitting and crevice corrosion, making it particularly suitable for chloride-containing environments. Duplex stainless steel, which contains both ferrite and austenite phases, provides greater strength and corrosion resistance than conventional austenitic stainless steel. In addition to alloying, nanocompositing involves uniformly dispersing nanoscale reinforcing phases—such as nanoparticles or nanofibers—within a matrix material to form a nanocomposite. This approach markedly enhances both mechanical performance and corrosion resistance. Material compounding and modification is a complex process that requires careful consideration of corrosion resistance, mechanical performance, manufacturability, and cost. When designing corrosion-resistant alloys, it is essential to consider how alloy composition, processing methods, heat treatment, and surface treatment collectively affect overall corrosion resistance.

Corrosion-resistant butterfly valve technology has made significant progress, with advances in understanding corrosion mechanisms, optimizing material properties, and enhancing manufacturing processes. The key role of localized corrosion and the core principles of material adaptation have been elucidated. The tailored use of metallic and non-metallic materials, combined with advancements in surface treatment and composite modification technologies, has effectively improved the reliability of butterfly valves in moderately to highly corrosive environments. Nevertheless, the industry still faces challenges, such as dependence on imported high-end materials, inadequate performance under extreme operating conditions, and the high cost and complexity of certain advanced technologies. Future developments in corrosion-resistant butterfly valve technology should concentrate on three key areas:

Material innovation: Developing cost-effective, high-performance alloys and new composite materials to optimize corrosion resistance, mechanical properties, and affordability.

Manufacturing technology upgrades: Implementing environmentally friendly surface treatment processes to replace traditional electroplating and integrating smart technologies for precise control of coating quality.

Integrated design optimization: Merging structural innovation with corrosion protection to develop butterfly valves that can withstand extreme operating conditions. Furthermore, enhancing collaboration among industry, academia, and research institutions is crucial to reduce reliance on imported high-end products, address the demands of emerging sectors such as nuclear power and new energy materials, and improve global competitiveness.