The fracture of the valve stem of the power station will affect the normal and stable operation of the power station equipment to a certain extent. In order to reduce the occurrence of accidents related to the power station, the operation and maintenance personnel of the power station should regularly replace the valve stem that is prone to breakage. The power station should do a good job in the training of relevant personnel, and strengthen the staff's awareness of operating norms to prevent the fracture of the valve stem caused by human factors. Under the premise of clarifying the reason for the breakage of the valve stem of the power station, how to take targeted measures is a problem that all relevant personnel needs to consider at present.

1. The analysis of the failure of the valve stem of the power station valve

1.1 Reasons for the failure of the valve stem of the power station valve

The breakage of the valve stem of the power station valve often occurs at the root of the upper and lower threads. The main reason is that the cross-sectional area of this part is small, which is prone to stress concentration. Through the investigation and analysis of the actual operation of the power station, it can be seen that excessive debugging makes the nut at the valve structure of the power station loose, and the bonnet shifts upward, causing the valve stem nut to be stuck, which in turn causes the valve stem of the power station to break. In addition, the fracture of the valve stem is likely to occur at the moment when the valve is opened. The main reason is that the internal pressure of the valve body rises suddenly after the cavity of the valve body is closed. The pressure overload inside the valve body after the valve is closed causes the root of the thread on the stem to break.

1.2 Inspecting

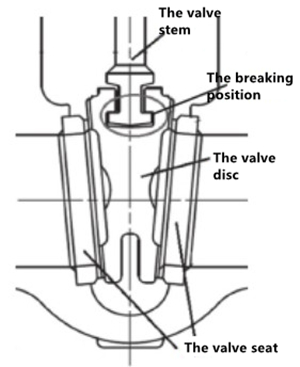

In order to find out the exact cause of the breakage of the valve stem of the power station, the test inspection was carried out with the valve stem that had broken and failed in a power station as the object. After checking, it was found that the connection between the valve stem and the valve disc was broken, and the material of the broken valve stem was S43100 martensitic stainless steel. After knowing the material of the valve stem, conduct in-depth research and analysis on the broken valve stem; quickly find out the reason for the breakage of the valve stem of the power station valve, and provide a reference for formulating solutions to reduce the occurrence of similar breakage and ensure the normal and stable operation of the power station to the greatest extent. The partial structure of the valve is shown in Figure 1.

Figure 1 Partial structure of valves

1.3 On-site investigation of fractures

The field investigation found that the fractured position of the valve stem is the connection part between the valve stem and the valve disc, and the surface of the connection area is relatively rough and has deep "groove marks". It is preliminarily judged that the appearance of the "groove" is mainly due to the defects left by the part during processing. When the part is subjected to external pressure, it is very easy to cause the "gap effect" on the surface of the part. In addition to this, many scratches were found on the sealing surface of the disc connecting to the valve stem, and there were also indentations of about 30 mm in the connecting area. After taking out the valve disc and checking it, it was found that special tooling was selected during installation. The analysis showed that when the valve stem of the power station valve broke, the valve disc connected to the valve was stuck between the two valve seats. By looking up the on-site operation records of the power station, it is shown that when the generator cannot operate normally, it needs to be operated manually. The valve disc connected to the valve is stuck between the two valve seats due to the lack of certain torque protection in manual operation, causing the valve stem not to move up or down, so that the contact area between the valve stem and the valve disc is subjected to excessive torsional moment, which affects the normal operation of the generator of the power station.