(1) Finite element simulation tests

Through the preliminary analysis of the reasons for the failure of the valve stem of the above-mentioned failures, it is understood that there is a certain relationship between the bearing force of the valve stem and the failure of the valve stem. In order to clarify the stress distribution at the connection between the valve stem and the valve disc of the power station valve during operation, a finite element simulation test was carried out on the basis of the preliminary analysis. To ensure the accuracy and reliability of the test results, when the bearing force simulation test was carried out, the proposed torsional moment parameters were input; the number of grid elements was divided at the same time, and the stress distribution at the valve stem joint was obtained by the test. Various data show that the chamfer of the variable section of the valve stem is the area with the great stress distribution at the joint between the stem and the valve disc, which was consistent with the actual fracture position of the valve stem of the power station valve.

(2) Chemical composition tests

The fractured stem is made of S43100 martensitic stainless steel. The chemical composition of the valve stem was tested, and it was found that the chemical composition contained in the material of the valve stem met the relevant technical standards through the analysis of various data.

(3) Chemical composition and hardness tests of metals and alloys

To check whether the structure and hardness of the metal and alloy of the valve stem were normal, the different parts of the valve stem were tested to determine whether the structure parameters and hardness of the valve stem fracture area meet the standard requirements. The hardness test results showed that the fractured valve stem has uneven hardness distribution, especially the hardness of the non-threaded part was significantly higher than that of the tail threaded area. It can be concluded that the hardness of the fractured valve stem was seriously inconsistent with the relevant standard requirements. It fully showed that the hardness of the valve stem has a certain relationship with the failure caused by the fracture of the valve stem of the power station valve.

(4) Tensile tests

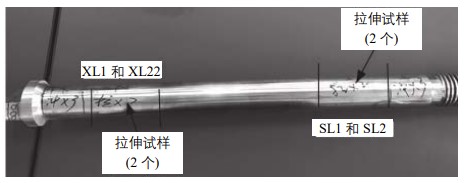

Tensile tests are carried out on different parts of the broken valve stem to confirm whether the tensile properties of the valve stem's material meet the requirements of relevant standards, as shown in picture 2.

Figure 2 Tensile tests of different parts of valve stems

Various data showed that although the tensile strength and yield strength of the fractured valve stem meet the requirements of the relevant standards, the elongation after fracture and the reduction in the area does not meet the requirements of the relevant standards. In addition, in order to confirm the toughness of the fractured valve stem's material, impact tests were also carried out on different parts of the valve stem. The test results showed that the toughness of the fractured stem material was relatively poor. The fracture and cross-section of the valve stem were observed with an electron microscope, and it was found that the fracture of the valve stem was relatively flat; there were primary and secondary cracks on the surface of the valve stem. The cracking surface with a smaller area is near the crack source, and the intergranular fracture is the main feature of the crack propagation zone and the instantaneous break zone in the shape of crystal sugar.

The fracture direction of the valve stem is vertical, and the grain profile attached to the surface was more obvious. The grain surface has claw mark-like tearing stripes, which was consistent with the brittle fracture along the grain caused by the hydrogen element. The fractured valve stem is made of S41300 martensitic stainless steel. Although the material has the advantages of high strength, it has poor toughness and plasticity, and is especially sensitive to hydrogen. Under the action of stress, the hydrogen element is enriched in the stress concentration area, which makes the valve stem of the power station valve very prone to hydrogen embrittlement. It can be seen that the fracture of the valve stem of the power station valve conforms to the characteristics of the intergranular brittle fracture caused by hydrogen elements.

1.5 The analysis of specific causes of the fracture

When the valve stem of the power station valve cannot be operated normally, manual operation is required. Since there is no torque protection for manual operation, the disc connected to the valve stem is stuck between the two valve seats. Combined with the analysis of the valve structure in Figure 1, it is found that when the valve stem cannot be pulled normally, a great torsional moment will be generated on the contact surface between the valve stem and valve disc. Under the effect of stress, when the valve stem bore the torsional moment, the chamfer of the variable section of the valve stem was the stress concentration point, that is, the breaking part of the valve. To sum up, when the valve stem of the power station valve cannot be pulled normally, it still needs to bear a great torsional moment, which will induce the valve to break. Because S41300 martensitic stainless steel is the main manufacturing material of the valve, the hardness of this material is significantly higher than the minimum value required by the relevant standards according to the hardness test results. The high hardness of the valve stem material will affect the normal lifting of the valve. It can be seen from the tensile test results that although the tensile strength is higher than the requirements of the relevant standards, the plasticity index does not meet the requirements of the relevant standards. In addition, the impact test results show that the impact absorption energy is low, which makes the overall impact performance of the valve stem material poor. In general, high strength, low toughness and low plasticity are the obvious characteristics of fractured valve stems, and the fractured valve stem material is relatively sensitive to hydrogen element and a notch effect of the surface. Under the effect of stress higher than the yield strength, the valve stem of the power station valve is very prone to hydrogen induced brittle fracture. In addition, "groove marks" appeared on the contact surface between the valve stem and the valve disc due to processing, which would cause the notch effect on the contact surface at the joint. It can be seen that the properties of the valve stem, the sensitivity to hydrogen embrittlement and the quality of processing are the essential reasons for the fracture of the valve stem of the power station valve.

1.6 Conclusion

Various tests were carried out on the broken valve stem, and the corresponding data were obtained. Through in-depth analysis and exploration of the data, it is concluded that the reasons for the fracture of the valve stem of the power station mainly involve the following aspects:

(1) Intergranular brittle fracture