In modern fluid transportation systems, the prevention of reverse flow is essential for protecting pipelines, pumps, and downstream equipment. Among the many types of non-return valves used across water treatment, oil and gas, petrochemical, and industrial HVAC systems, the tilting disc check valve stands out for its efficiency, rapid response, and dependable sealing performance. As industries continue to demand higher reliability and improved energy efficiency in fluid systems, the tilting disc check valve has increasingly become a preferred option for engineers and international project contractors.

This news article provides an in-depth examination of the tilting disc check valve—its structure, working principle, comparison with common check valves, advantages, limitations, and the key applications shaping its market growth. It also explores how advances in materials and standards such as API 594 and API 598 ensure consistent performance and long service life. Whether in municipal water pipelines, gas systems, or high-pressure industrial networks, understanding how the tilting disc check valve functions is essential for making informed decisions about system optimization.

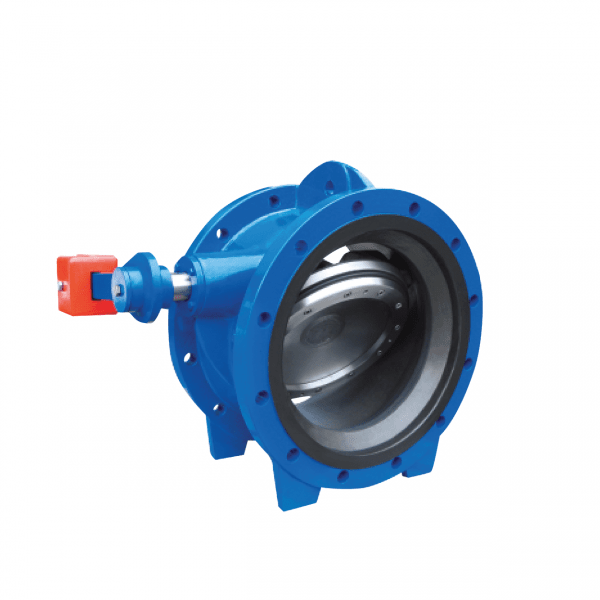

A tilting disc check valve is a one-way valve designed to allow flow in a single direction while preventing any form of reverse movement of liquid or gas. The valve operates automatically, without the need for external actuation. When forward flow occurs, the medium pushes the disc open. When flow slows or reverses, gravity and reverse pressure cause the tilted disc to close quickly and smoothly. Because of this fast response, the valve minimizes water hammer, one of the most damaging phenomena in fluid transfer systems.

Unlike full-swing or lift-type check valves, the tilting disc model features a disc installed at an angle—rather than vertically—allowing it to respond more efficiently to low flow rates and changes in pressure. This unique structure makes it especially suitable for critical systems where sudden reverse flow could cause pressure surges or mechanical damage.

Standard design, manufacturing, and testing practices for tilting disc check valves commonly follow internationally recognized guidelines, such as:

API 594 – Covers design and face-to-face dimensions for check valves

API 598 – Specifies valve inspection and testing requirements

ASME B16.5 / B16.47 – Flange dimensions for various pressure classes

ISO standards for global compliance

These standards ensure high safety, accuracy, and durability, making the tilting disc check valve a dependable solution for both new installations and system upgrades.

The primary purpose of any check valve is to prevent backflow. However, the tilting disc check valve is specifically engineered to improve flow characteristics and reduce pressure loss. Because the disc tilts open instead of swinging fully, it maintains a streamlined flow path, minimizing turbulence and energy consumption.

Industries rely on tilting disc check valves to:

Prevent reverse flow in critical systems

Reduce water hammer and protect pumps

Improve overall system efficiency

Operate reliably with minimal maintenance

Provide long service life under various pressure and temperature conditions

This combination of performance and safety makes the valve essential in many applications, from municipal water networks to complicated refinery systems.

Check valves come in many forms—swing type, lift type, wafer type, dual-plate, ball style, and more. While all serve the same basic purpose, their designs differ, influencing efficiency, sealing, and suitability for different media.

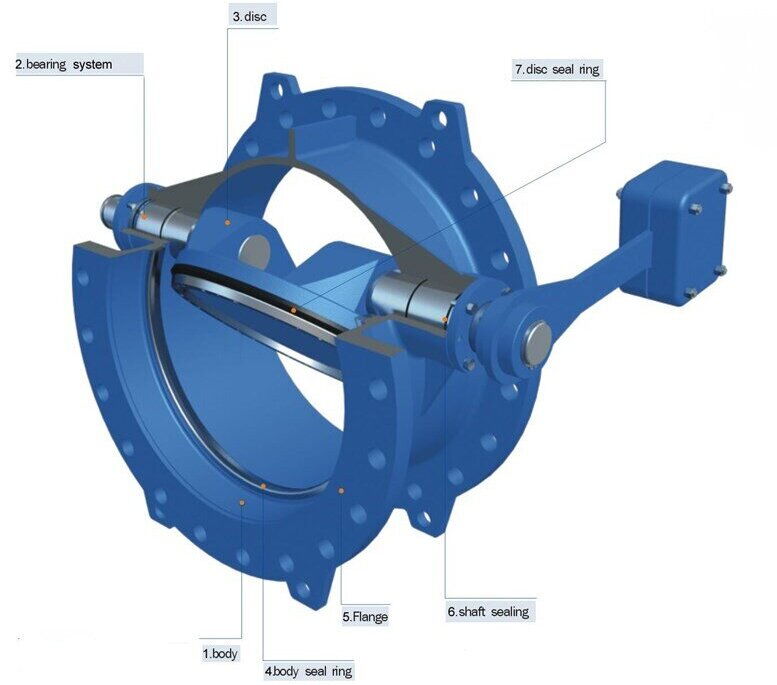

The tilting disc check valve features:

A disc mounted at an inclined angle

A hinge mechanism that allows smooth rotation

A short travel distance for quick response

A streamlined flow path reducing head loss

Metal or soft sealing options depending on operating conditions

Typically wafer or flanged connections

The tilted disc geometry allows fluid to pass nearly unobstructed during forward flow. Because the disc is partially supported in the flow stream, even low velocities can keep it open. When reverse pressure occurs, the disc tilts back into the seat almost immediately.

In contrast, common check valves may employ:

Swing discs that rotate fully like a door

Lift discs that move vertically using spring force

Ball mechanisms that seal against a seat

Dual plates that hinge open in two segments

While these designs are often effective, they typically require higher flow velocity to open fully and may generate more turbulence. Some common types, such as swing check valves, also have longer travel distances, resulting in slower closure and increased water hammer risk.

Understanding the mechanics of check valve operation is essential when choosing the right type for a pipeline.

The valve opens using the momentum of forward flow. Because the disc is tilted, only a small amount of pressure is needed to begin opening the valve. The disc stabilizes at an angle that corresponds to the flow rate. As flow decreases, the disc automatically begins to close, preventing reverse flow even before full backflow occurs.

In the event of flow reversal, the disc closes rapidly due to:

Reverse pressure

Disc weight

Optimized hinge design

This quick response minimizes water hammer—one of the biggest advantages of this design.

Common check valves rely heavily on:

Gravitational forces

Flow velocity

Spring tension (in lift check valves)

Swing check valves tend to close more slowly because the disc must travel a longer arc. Lift check valves can close faster but may be more susceptible to blockage from impurities. Ball check valves work well for viscous fluids but are less effective in systems requiring low-pressure operation.

Tilting disc check valves are versatile and suitable for handling:

Clean water

Potable and municipal water systems

Steam lines

Oil and gas pipelines

Chemical processing fluids

Air and non-corrosive gases

Key industries using tilting disc check valves include:

Water supply and wastewater treatment

Petrochemical and refinery operations

Power generation and thermal plants

Industrial HVAC systems

Marine and offshore engineering

Because they respond well to low flow rates, they are excellent for pump discharge lines, cooling systems, and distribution networks where pressure fluctuations frequently occur.

Despite their advantages, tilting disc check valves are not recommended for:

Fluids containing suspended solids or debris

Slurry or sewage systems

Highly viscous or sticky media

Solids can obstruct disc movement and interfere with proper seating, reducing performance and shortening service life.

Unlike complicated valve types requiring actuators, the tilting disc check valve is inherently automatic. However, depending on system requirements, it may include additional features for enhanced operability.

Fully automatic based on flow direction

Sensitive to low flow rates

Can be installed horizontally or vertically depending on design

Optional features may include:

Position indication

Dampers to control closure speed

Special seats for high-temperature or corrosive environments

Most common check valves are also automatic, but some require:

Higher flow velocity to open

More installation restrictions

Manual inspection or adjustment in some models

Because of their slower action and larger disc swing radius, swing check valves often produce greater water hammer in large-diameter pipelines.

The design of tilting disc check valves provides many performance benefits that engineers appreciate:

Their fast closure significantly reduces pressure surges, protecting pumps, pipes, and meters.

The streamlined internal structure minimizes turbulence and energy loss.

Even low velocity is enough to keep the disc open, making it suitable for systems with variable flow.

Wafer and short face-to-face dimensions allow easy installation in tight spaces.

Robust construction and high-quality sealing materials ensure durability in industrial conditions.

Common materials include:

Carbon steel

Stainless steel (CF8/CF8M)

Duplex stainless steel

Alloy steels for high temperature

Metal or soft seat options accommodate different pressures and temperatures.

The market demand for tilting disc check valves continues to grow as industries upgrade aging infrastructure and adopt energy-efficient flow control systems. Key trends include:

Increased use in large-scale water transmission lines

Expansion in Arab, Southeast Asian, and African water projects

Growing adoption in LNG, petrochemical, and refinery sectors

Strong demand for corrosion-resistant duplex and super duplex materials

Development of smart valve monitoring systems

With global water scarcity challenges and rapid industrialization, the reliability and efficiency of non-return valves will remain crucial.

The tilting disc check valve has evolved into one of the most efficient and reliable solutions for preventing reverse flow in modern fluid systems. Its unique structural design, quick action, low-pressure drop, and suitability for a wide range of media make it indispensable across industries. Compared with traditional check valves, the tilting disc model offers improved performance, enhanced protection against water hammer, and long-term operational stability.

As global infrastructure continues to expand and system performance standards rise, the tilting disc check valve will remain an essential component in ensuring safety, reliability, and energy efficiency in pipelines worldwide.