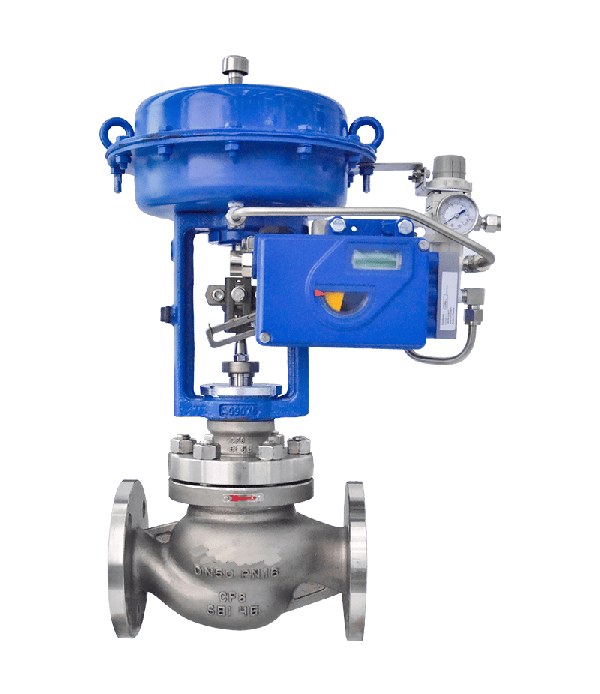

In industrial fluid control systems, precision, reliability, and durability are critical for ensuring efficient operations. The Pneumatic Single-Seat Globe Control Valve is a high-performance valve designed to meet the demanding requirements of applications involving high differential pressures, heavy-duty service, and challenging conditions such as flashing and cavitation. With its robust construction, advanced design features, and exceptional flow control capabilities, this valve is a trusted solution for industries ranging from oil and gas to chemical processing. This article provides an in-depth look at the Pneumatic Single-Seat Globe Control Valve, exploring its design, performance characteristics, and applications.

The Pneumatic Single-Seat Globe Control Valve is engineered for high differential pressure service, where fluid pressure exceeds 2940 kPa (30 kgf/cm²), and for heavy-duty applications where flashing or cavitation may occur. Its design ensures reliable performance, even in the most challenging environments. Below are the key specifications and features of this valve:

Body Type: Straight-through, cast globe valve

Valve Action:

FO (Fail-Open): Air to close (direct action actuator)

FC (Fail-Close): Air to open (reverse action actuator)

Flow Characteristics: Equal percentage or linear

Leakage Performance:

Metal Seat: ANSI B16.104 Class II, leakage less than 0.5% of maximum valve capacity

Soft Seat: ANSI B16.104 Class VI, leakage less than 0.00001% of maximum valve capacity

The Pneumatic Single-Seat Globe Control Valve is packed with advanced features that make it a reliable and efficient choice for industrial applications. Here are some of its standout characteristics:

Designed to handle high differential pressures exceeding 2940 kPa (30 kgf/cm²), this valve is ideal for applications involving significant pressure drops.

The valve’s sturdy guides and cage-protected body prevent erosion and ensure long-lasting performance, even in heavy-duty service conditions.

The compact valve body features an S-shaped flow passage that minimizes pressure loss while maximizing flow capacity and rangeability.

The valve plugs are available in a wide range of Cv values, allowing for precise flow control across various applications.

The valve’s simple yet effective mechanism ensures reliable flow shutoff, with leakage rates compliant with ANSI B16.104 standards.

The valve is equipped with a compact yet powerful diaphragm actuator loaded with multiple springs, providing precise and responsive control.

The valve supports both fail-open (FO) and fail-close (FC) configurations, making it suitable for a wide range of operational requirements.

The Pneumatic Single-Seat Globe Control Valve delivers exceptional performance across various parameters, ensuring reliable and efficient operation. Here are its key performance characteristics:

Equal Percentage: Provides fine control at low flow rates and increased sensitivity at higher flow rates, making it ideal for applications requiring precise modulation.

Linear: Offers a consistent flow rate relative to valve position, suitable for applications requiring proportional control.

Metal Seat: Complies with ANSI B16.104 Class II, with leakage less than 0.5% of maximum valve capacity.

Soft Seat: Complies with ANSI B16.104 Class VI, with leakage less than 0.00001% of maximum valve capacity, ensuring near-zero leakage for critical applications.

The valve is designed to operate under high differential pressures and a wide range of temperatures, making it suitable for demanding industrial environments.

The valve’s robust construction and high-quality materials ensure long-term durability and reliable performance, even in harsh conditions.

The Pneumatic Single-Seat Globe Control Valve is widely used in various industries due to its versatility and reliability. Here are some of its key applications:

The valve is used in upstream, midstream, and downstream operations, including wellhead control, pipeline management, and refining processes.

In chemical plants, the valve is used for precise flow control in processes involving corrosive and abrasive media.

The valve is employed in power plants for steam control, cooling water systems, and fuel handling.

The valve is used in water treatment plants for flow control in filtration, disinfection, and sludge handling processes.

The valve’s precise control and leak-tight performance make it suitable for applications requiring hygienic and contamination-free operations.

The valve is used in processes such as pulp digestion, bleaching, and paper coating, where it handles abrasive and corrosive media with ease.

The Pneumatic Single-Seat Globe Control Valve offers numerous advantages that make it a preferred choice for industrial applications. Here are some of its key benefits:

The valve’s design ensures reliable operation under high differential pressures and in applications involving flashing, cavitation, and erosion.

The valve’s wide range of Cv values and flow characteristics enable precise control over fluid flow, ensuring optimal process performance.

The valve’s metal and soft seat options provide leak-tight performance, meeting stringent industry standards for leakage control.

The valve’s robust construction and high-quality materials ensure long-lasting performance, reducing maintenance costs and downtime.

The valve’s compact design, versatile valve action, and compatibility with various media make it suitable for a wide range of applications.

The valve’s simple yet effective design simplifies maintenance and reduces operational costs.

The Pneumatic Single-Seat Globe Control Valve is a high-performance solution designed to meet the demanding requirements of modern industrial applications. With its robust construction, advanced design features, and exceptional flow control capabilities, this valve is a reliable choice for industries ranging from oil and gas to chemical processing and power generation.

Whether you’re managing high differential pressures, handling corrosive or abrasive media, or requiring precise flow control, the Pneumatic Single-Seat Globe Control Valve delivers unmatched performance and reliability. By choosing this valve, industries can achieve optimal process efficiency, reduce downtime, and maintain the highest standards of safety and quality.

In a world where precision and durability are critical, the Pneumatic Single-Seat Globe Control Valve stands out as a trusted partner for industrial fluid control.