In the evolving world of fluid handling and process control, industrial valves remain central to operational safety, efficiency, and reliability. Among these, the soft seated floating ball valve has emerged as one of the most versatile and widely adopted valve types across energy, chemical, water treatment, oil & gas, and manufacturing sectors. Thanks to its compact design, superior sealing performance, and broad material compatibility, this valve type continues to reshape how engineers and plant operators solve leakage challenges and optimize system performance.

This article explores the technical advantages, market trends, application scenarios, manufacturing innovations, quality standards, and future outlook for soft seated floating ball valves — offering an in-depth view for professionals, procurement specialists, and technical audiences.

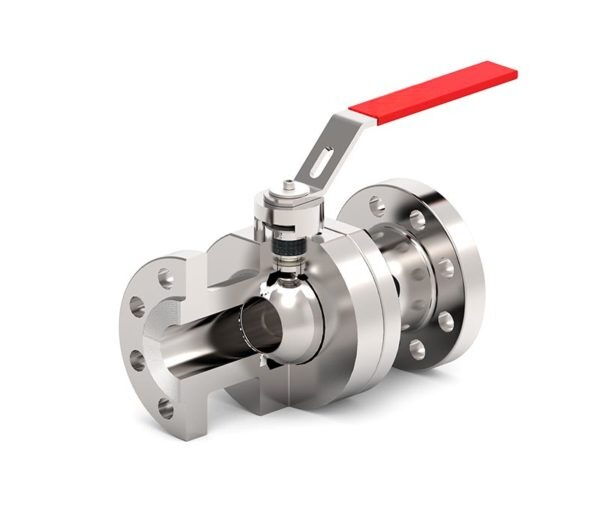

At its core, a floating ball valve uses a spherical closure element (the ball) that rotates around a central axis to control flow. The “floating” designation means the ball is not fixed; instead, it is supported by two soft seats that allow the ball to move slightly downstream under pressure — creating a tight seal between the ball and seat.

The term soft seated refers to seats made from resilient polymers such as:

PTFE (Polytetrafluoroethylene) — known for chemical resistance and low friction

RPTFE (Reinforced PTFE) — enhanced strength and wear resistance

PEEK (Polyether Ether Ketone) — high temperature performance

ELASTOMERS (e.g., EPDM, Viton) — flexible sealing in varied media

Unlike metal-seated valves, soft seats conform more closely to the ball surface, yielding near-bubble-tight shut-off performance — a critical requirement in applications where leak prevention is mandatory.

The defining feature of soft seated floating ball valves is bubble-tight shut-off — typically achieving Class VI leak performance standards. This is crucial for applications involving:

- Toxic or hazardous fluids

- High-purity gases and liquids

- Compressed air systems

- Steam utilities

A well-designed soft sealed valve prevents fugitive emissions and minimizes product loss, directly impacting safety compliance and operational cost.

Because the ball does not require metal-to-metal contact with seats, these valves exhibit lower torque requirements compared to metal seated alternatives. This means:

- Easier actuation (manual, pneumatic, or electric)

- Reduced actuator size and energy consumption

- Longer service life with reduced wear

Lower torque also enhances automation compatibility, as many modern plants deploy electric or pneumatic actuators controlled via distributed control systems (DCS) or PLCs.

Soft materials such as PTFE exhibit excellent resistance to:

- Acids and alkalis

- Solvents

- Corrosive chemicals

- Slurries and process fluids

This versatility makes soft seated floating ball valves a preferred choice in chemical processing, petrochemicals, pharmaceuticals, and food/beverage manufacturing.

Compared to gate or globe valves with equivalent rated sizes, soft seated floating ball valves tend to be more compact and lighter. This provides engineers with:

- Space savings in congested skid or panel layouts

- Easier installation and maintenance

- Lower support infrastructure requirements

Manufacturers often offer floating ball valves with varying port designs:

Full bore (full port) — same diameter as the pipeline, minimizing pressure drop

Reduced bore — smaller than pipeline diameter but suitable where cost or weight limits matter

Full port valves are advantageous for pigging operations, slurry handling, or any application demanding minimal flow restriction.

Soft seated floating ball valves provide unmatched utility in multiple sectors. Here are some primary applications illustrating their versatility:

In upstream, midstream, and downstream facilities, soft seated floating ball valves function in:

- Liquid hydrocarbon services

- Gas distribution lines

- Chemical injection systems

- Utility services

Here, reliability against leaks, ease of automation, and compatibility with process media determine valve selection — and soft seated floating ball valves deliver these performance attributes consistently.

From potable water to reclaimed wastewater systems, these valves control flow in:

- Filtration trains

- Chemical dosing systems

- Pump isolation

- Effluent discharge

The low maintenance and corrosion-resistance of polymer seats make them suitable for treated water streams and aggressive cleaning chemicals alike.

Chemical plants handle a spectrum of fluids — ranging from corrosive acids to high-viscosity organics. Soft seated floating ball valves:

- Withstand aggressive media

- Minimize downtime

- Allow precise on/off control

They are commonly found in metering systems, solvent transfer lines, and batch processing units.

Strict sanitation and leakage control standards in these sectors necessitate valves with:

- Clean sealing surfaces

- Minimal dead zones

- FDA/3A compliant seat materials

Soft seats like PTFE deliver low friction and cleanability — vital in applications like CIP (clean-in-place) systems, ingredient lines, and sterile gas routes.

Whether controlling steam, cooling water, or auxiliary fuel lines, floating ball valves with PTFE seats offer:

- Reliable shut-off

- Rapid cycling

- Low torque

- Solid sealing under variable temperatures

This proves essential in both fossil and renewable power plants.

As demand grows, valve manufacturers continue pushing advancements in materials, design, and production quality.

Newer composite and engineered polymers are expanding operational envelopes. High-temp PTFE composites, filled PTFE blends, and PEEK-reinforced seats now enable soft seated valves to reach higher pressure and temperature ratings without sacrificing sealing performance.

Using finite element analysis (FEA), manufacturers optimize seat geometry for:

- Uniform compression distribution

- Reduced wear zones

- Lower actuation force

This computational design approach improves reliability and extends service life.

Enhanced surface treatments such as:

- Electropolishing

- DLC (Diamond-Like Carbon) coatings

- Chrome plating

yield smoother ball surfaces that reduce friction with soft seats and deliver consistent sealing over millions of cycles.

Soft seated floating ball valves must meet several recognized industry standards to ensure reliability, safety, and interchangeability. Some relevant standards include:

API 598 — Valve Inspection and Test

API 6D — Pipeline Valves

ASME B16.34 — Valves Flanged, Threaded, and Welding End

ISO 5208 — Industrial valves — Pressure testing

ANSI/FCI 70-2 — Control Valve Seat Leakage

Manufacturers typically perform shell tests, seat leakage tests, and endurance cycling to confirm compliance. Class VI leakage performance — one of the strictest — is especially important for soft seated valves in critical isolation applications.

Modern process systems increasingly incorporate automated valves with smart diagnostics. Soft seated floating ball valves — due to low torque and predictable behavior — are well suited for:

- Digital positioners

- Predictive maintenance sensors

- IoT-connected valve performance analytics

Integration with plant control systems enables real-time health monitoring, reducing unplanned downtime.

Stricter environmental regulations on emissions and fugitive releases are pushing end users to adopt valves with verified sealing integrity. Soft seated designs with robust seat materials deliver reliable sealing performance that aligns with environmental compliance efforts and reporting.

As industries transition toward cleaner energy sources, including hydrogen and biofuels, specialty valve requirements evolve. Soft seated floating ball valves are being adapted with compatible materials for emerging media — positioning them as a flexible solution in transitional energy markets.

Operators now evaluate valves not just on upfront cost but on total lifetime value. Soft seated floating ball valves — with low maintenance, long service intervals, and automation readiness — often achieve lower TCO in comparison to other valve technologies.

Despite their advantages, soft seated floating ball valves have limitations that engineers must consider:

Polymer seats generally cannot tolerate extremely high temperatures or abrasive fluids compared to metal seated valves. Application engineers must select appropriate seat materials and designs to avoid premature wear or deformation.

Processes involving particulate matter — like slurries or highly abrasive fluids — can accelerate seat degradation. In such cases, enhanced seat materials or alternative valve types might be more suitable.

Under specific pressure drop conditions, cavitation or flashing can occur, causing erosion of internal components. Proper valve sizing and the use of anti-cavitation trims are essential to mitigate these phenomena.

To maximize performance and service life, soft seated floating ball valves require proper handling and installation:

- Follow manufacturer torque specifications to avoid seat damage during actuator mounting

- Use proper alignment and support to prevent pipeline stress

- Avoid over-tightening flange bolts — this can warp valve bodies and affect sealing

- Periodic inspection and testing should be integrated into maintenance schedules

- Replace seats based on application severity rather than on a fixed calendar cycle

It is also recommended to maintain records of operational cycles, temperature exposure, and service incidents to forecast valve servicing needs more accurately.

Case 1: Chemical Processing Plant Reduces Leaks by 90%

In a major chemical plant handling corrosive acids and solvents, legacy valves experienced frequent leakage and maintenance issues. After retrofitting key isolation points with soft seated floating ball valves featuring reinforced PTFE seats, plant managers reported:

Dramatic reduction in leakage events

Improved worker safety

Less maintenance downtime

The result was improved throughput and enhanced compliance with regulatory audits.

Case 2: Water Utility Achieves Energy Savings Through Automation

A large municipal water utility automated several isolation valves in a pumping station. By selecting soft seated floating ball valves with low torque requirements, the utility deployed smaller, energy-efficient electric actuators. This reduction in operational power demand contributed to measurable energy cost savings with minimal installation complexity.

Case 3: Oil & Gas Facility Improves Emission Control

At a mid-stream facility with strict emission monitoring, installing soft seated floating ball valves with enhanced seat sealing helped the operator achieve better fugitive emission performance — supporting environmental goals and regulatory compliance.

The future of soft seated floating ball valves points toward further integration with digital transformation trends. Areas of anticipated advancement include:

Embedded sensors capable of monitoring:

- Seat wear

- Cycle count

- Leakage trends

- Temperature and vibration anomalies

will empower predictive maintenance and reduce unplanned outages.

Research into advanced polymers, hybrid materials, and nanocomposite seat structures promises to expand the operating envelope, enabling soft seated solutions for even harsher environments.

As sustainability becomes a core business priority, valves with long service lives and low environmental impact — from manufacturing through disposal — will gain preference. Soft seated floating ball valves are well positioned due to their recyclable components and reduced leakage profiles.

The soft seated floating ball valve stands at the intersection of performance, reliability, and versatility in fluid control technology. With superior sealing, adaptability across industries, and compatibility with automation trends, it continues to be a cornerstone in modern process systems.

As markets evolve and demands for efficiency, safety, and environmental stewardship grow, engineers and operators alike are turning to this proven valve design to meet present and future challenges.

For procurement specialists, technical decision-makers, and plant operators, understanding the nuances — from material selection to performance testing — is key to unlocking the full value of soft seated floating ball valves in industrial applications.