Brass gate valves are essential components in various plumbing and industrial systems, known for their durability, strength, and resistance to corrosion. Made from brass, an alloy of copper and zinc, these valves are widely used due to their excellent machinability, cost-effectiveness, and compatibility with a range of fluids. This article delves into the specifics of brass gate valves, their types, applications, and maintenance tips, providing a comprehensive understanding of their role in modern systems.

Brass valves are mechanical devices used to control the flow of liquids or gases in pipelines. They are constructed from brass, a material chosen for its unique properties, including strength, corrosion resistance, and ease of machining. Brass valves come in various types, each designed for specific applications. The most common types include ball valves, gate valves, globe valves, and check valves. Among these, brass gate valves are particularly notable for their ability to regulate fluid flow with precision and reliability.

Brass is a preferred material for valve construction due to several advantageous properties:

Brass can withstand high pressures and extreme temperatures, making it suitable for demanding environments.

Brass is highly resistant to corrosion, which is crucial for applications in marine, coastal, and industrial settings.

Brass is easy to machine, allowing for the production of customized valves tailored to specific requirements.

Compared to materials like stainless steel, brass is more affordable, making it a cost-effective choice for valve manufacturing.

Brass is compatible with a wide range of fluids, including water, oil, gas, and chemicals, making it versatile for various industries.

A brass gate valve is a type of valve used to control the flow of liquids in a pipeline. It operates by lifting or lowering a gate (a flat or wedge-shaped disc) to either allow or block the flow of fluid. The gate valve is named for its gate-like mechanism, which moves up and down within the valve body to regulate flow. Brass gate valves are known for their ability to provide a tight seal, making them ideal for applications where a complete shut-off is required.

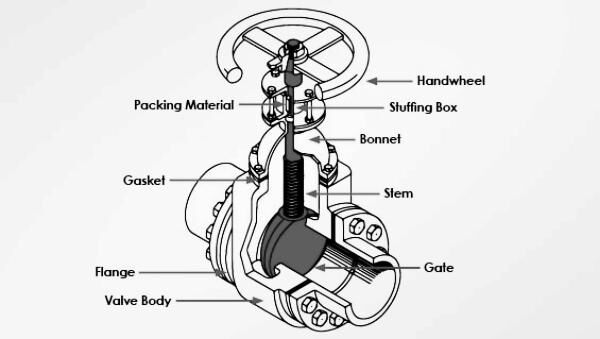

Understanding the components of a brass gate valve is crucial for selecting the right valve for your system. The main parts include:

The handwheel is used to manually operate the valve. Turning the handwheel raises or lowers the gate, controlling the flow of fluid.

The stem connects the handwheel to the gate. It transfers the rotational motion of the handwheel into linear motion, moving the gate up or down.

The gate is the component that blocks or allows the flow of fluid. It can be either a sliding type or a wedge type, depending on the application.

The valve body houses the internal components and is designed to be attached to the pipeline. It can have flanged, threaded, or weldable joints.

The bonnet covers the valve body and protects the internal components from external damage. It also helps prevent leaks.

Seals and packing are used to prevent leaks and protect the valve from wear and tear, ensuring long-term functionality.

Brass gate valves are versatile and find applications in various fields, including:

Brass gate valves are commonly used in home plumbing systems to control water supply and drainage. They are ideal for applications where a reliable shut-off is needed.

In industrial settings such as factories, chemical plants, and oil refineries, brass gate valves are used to control the flow of liquids and gases. Their durability and resistance to corrosion make them suitable for harsh environments.

Brass gate valves are used in irrigation systems to regulate the flow of water in pipelines, ensuring efficient water distribution.

Due to their corrosion resistance, brass gate valves are widely used in marine and offshore environments, where exposure to saltwater can cause other materials to degrade.

In heating, ventilation, and air conditioning (HVAC) systems, brass gate valves are used to control the flow of heating and cooling fluids, ensuring optimal system performance.

Brass gate valves come in several types, each designed for specific applications. The most common types include:

These valves feature a wedge-shaped gate that provides a tight seal, making them ideal for applications where a complete shut-off is required.

In these valves, the gate is parallel to the flow of fluid. They are typically used in applications where a tight seal is not necessary.

These valves have a stem that moves up and down outside the valve body, making them easy to maintain and repair.

In rising stem gate valves, the stem moves up and down as the valve is operated, providing a visual indication of the valve's position.

These valves have a stem that does not move up and down, making them suitable for applications with limited space.

Proper installation and maintenance are crucial for the optimal performance and longevity of brass gate valves. Here are some tips to ensure your valves function effectively:

Ensure that the valve is installed in the correct orientation, with the flow direction matching the arrow on the valve body. Use appropriate sealing materials, such as Teflon tape or pipe dope, to prevent leaks.

Periodically inspect the valve for signs of wear, corrosion, or damage. Check the seals and packing for leaks and replace them if necessary.

Lubricate the stem and handwheel regularly to ensure smooth operation. Use a lubricant that is compatible with brass and the fluids being handled.

Operate the valve periodically to ensure it moves freely and provides a tight seal. If the valve becomes difficult to operate, it may need maintenance or replacement.

Keep the valve clean and free from debris that could interfere with its operation. In corrosive environments, consider using protective coatings to extend the valve's lifespan.

Brass gate valves are indispensable components in a wide range of applications, from residential plumbing to industrial systems. Their strength, durability, and resistance to corrosion make them a reliable choice for controlling the flow of liquids and gases. By understanding the different types of brass gate valves and their applications, as well as following proper installation and maintenance practices, you can ensure the optimal performance and longevity of these essential devices. Whether you're managing a home plumbing system or overseeing an industrial operation, brass gate valves offer the reliability and efficiency needed to keep your systems running smoothly.