In the ever-evolving landscape of industrial engineering, few components carry as much importance as valves. They regulate, guide, and safeguard fluid flow across a wide spectrum of industries—ensuring efficiency, safety, and sustainability. Among the many types of valves available today, the aluminum bronze ball valve has carved out a special place as a durable and corrosion-resistant solution tailored for the world’s most demanding environments.

Constructed from ASTM B148 aluminum bronze, this valve is designed to withstand challenges that would quickly degrade other materials, including constant exposure to seawater, salt solutions, aggressive chemicals, and abrasive fluids. Its compact ball mechanism provides tight shut-off and smooth, reliable flow control, while the alloy’s strength ensures long service life with minimal maintenance.

From offshore oil platforms to desalination plants, from marine engineering to chemical processing, the aluminum bronze ball valve has become indispensable for industries where reliability is not optional but essential.

This comprehensive news feature explores the material science behind aluminum bronze, the design of ball valves, their applications, advantages, maintenance considerations, and their growing role in global infrastructure.

Aluminum bronze is a copper-based alloy containing aluminum as its primary alloying element (typically between 6–12%), often enhanced with iron, nickel, or manganese for added strength and durability. This alloy was first developed in the 19th century, gaining recognition for its resistance to corrosion in marine environments—a property that made it ideal for naval applications, ship propellers, and later, offshore equipment.

By the 20th century, aluminum bronze had become a standard material for industrial equipment that faced seawater exposure, outperforming many stainless steels that suffered from chloride stress corrosion cracking. The alloy’s ability to combine strength, toughness, and corrosion resistance set it apart from conventional bronzes and brasses.

Today, the most common grade for valves is ASTM B148 C95800, which offers:

Excellent resistance to seawater and saltwater corrosion.

High mechanical strength comparable to low alloy steels.

Resistance to cavitation and erosion.

Non-sparking and non-magnetic properties, adding safety in sensitive environments.

This historical development explains why aluminum bronze became the preferred choice for ball valves in industries where seawater and aggressive fluids are unavoidable.

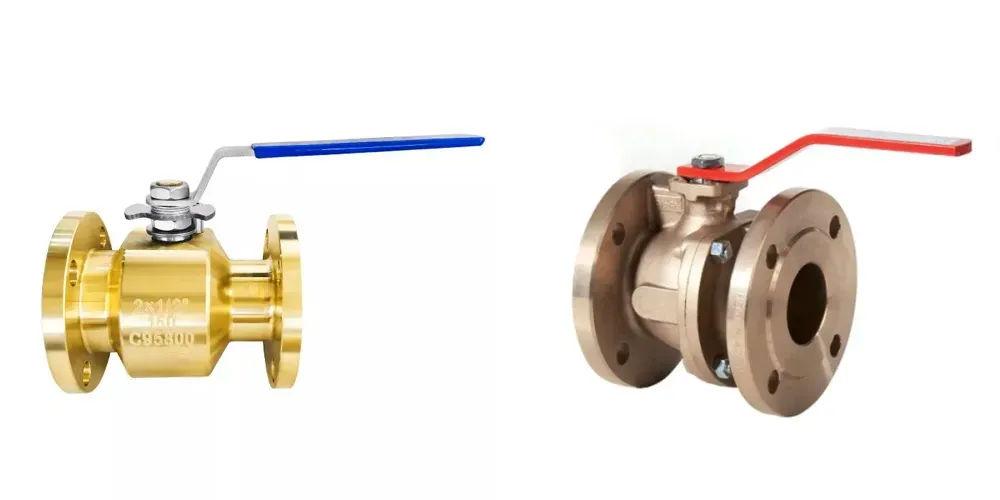

An aluminum bronze ball valve is a quarter-turn valve that uses a spherical ball with a bore to control fluid flow. By turning a handle or actuator, the ball either aligns with the pipeline to allow flow or rotates to block it completely. This simple yet efficient design makes aluminum bronze ball valves highly reliable in demanding service conditions.

These valves are widely applied in chemical processing, industrial systems, and marine environments, where corrosion resistance and mechanical strength are critical.

When choosing the right aluminum bronze ball valve, businesses must weigh factors such as application requirements, operating conditions, and budget. For instance, if comparing with stainless steel ball valves, decision-making often comes down to whether the service environment requires superior resistance to corrosion and rust, particularly in outdoor or seawater-exposed installations.

Valve Body & Ball: Made from ASTM B148 C95800 aluminum bronze.

Seats: Typically PTFE (Teflon), RPTFE, or reinforced elastomers for leak-tight sealing.

Stem: Designed for strength, often with blow-out proof features.

Operation: Manual lever, gear-operated, or automated with electric, pneumatic, or hydraulic actuators.

End Connections: Flanged, threaded (NPT/BSP), or welded depending on application.

Floating Ball Valves: The ball floats slightly downstream to create a seal with the seat. Common for small- to medium-sized valves.

Trunnion-Mounted Ball Valves: The ball is anchored by trunnions, reducing torque requirements and allowing use in high-pressure and large-diameter applications.

The choice between these designs depends on factors such as pressure, size, and service environment.

The simplicity of operation makes aluminum bronze ball valves attractive:

Open Position: The ball’s bore aligns with the pipeline, allowing full flow.

Closed Position: The ball rotates 90 degrees, blocking the bore and stopping flow.

Throttling (Limited Use): While not ideal for throttling, some designs allow partial openings to regulate flow.

The valve’s tight sealing reduces leakage risk, an especially critical feature in industries handling hazardous fluids like hydrocarbons or corrosive chemicals.

The versatility of aluminum bronze ball valves is reflected in their wide adoption across multiple sectors.

Ship Fuel Systems: Manage diesel and biofuel with minimal corrosion risk.

Seawater Cooling: Essential in marine engines and offshore platforms.

Ballast Water Management: Control intake and discharge with reliability.

Subsea Applications: Withstand immense pressure while resisting seawater corrosion.

Offshore Platforms: Handle firewater and seawater injection systems.

Onshore Processing Plants: Regulate flow of corrosive chemicals and brines.

Refineries & LNG Facilities: Depend on reliable shut-off in safety-critical systems.

Control high-salinity flows in desalination plants.

Reduce maintenance downtime in large-scale municipal water systems.

Safely handle acids, alkalis, and chemical solutions.

Provide long service life in brine-rich production environments.

Coastal Power Plants: Utilize aluminum bronze valves in seawater cooling systems.

Nuclear Facilities: Deploy valves in auxiliary water systems requiring reliability.

In each of these industries, the material choice directly impacts safety, efficiency, and operational cost.

Unmatched Corrosion Resistance – Perform reliably in seawater and saline solutions where stainless steel often fails.

High Mechanical Strength – Withstand high pressure and dynamic loads.

Reduced Maintenance – Longer life means fewer replacements and lower costs.

Non-Sparking & Non-Magnetic – Enhances safety in explosive or sensitive environments.

Versatility – Available in a wide range of sizes, designs, and end connections.

Cost-Effectiveness Over Time – Higher upfront cost offset by lower lifecycle expenses.

While these valves are highly reliable, industries must also consider:

Higher Initial Cost compared to standard bronze or cast iron valves.

Weight in larger diameters, requiring stronger support structures.

Material Compatibility: Not suitable for strong oxidizing acids like nitric acid.

Proper maintenance ensures extended valve life:

Regular Inspection: Monitor for signs of seat wear or corrosion.

Seal Replacement: Replace O-rings and seats as part of preventive maintenance.

Lubrication: Use marine-grade lubricants to protect against seawater ingress.

Exercise Valves: Periodically operate to prevent sticking.

Calibration (Automated Systems): Check actuators regularly for accuracy.

By following these practices, industries can maximize ROI on aluminum bronze ball valves.

The demand for aluminum bronze ball valves is expected to rise significantly over the next decade, driven by:

Growth of Offshore Oil & Gas: As exploration moves into deeper waters.

Expansion of Desalination Plants: Particularly in the Middle East and coastal Asia.

Marine Shipping Industry: Increased global trade means more vessels requiring seawater-resistant valves.

Renewable Energy Projects: Offshore wind farms and tidal energy projects also demand corrosion-resistant components.

Market analysts forecast that the global marine and offshore valve market will grow steadily, with aluminum bronze valves holding a strong share due to their proven performance.

Smart Valve Integration: Sensors and IoT-enabled actuators allow real-time monitoring of valve position, pressure, and flow.

Advanced Seat Materials: Development of new polymers and composites improves sealing performance.

Hybrid Designs: Combination of aluminum bronze bodies with specialized coatings for enhanced resistance.

Sustainability: Longer lifespan reduces waste and supports green industry goals.

These innovations will ensure aluminum bronze ball valves remain relevant in future industrial infrastructures.

The aluminum bronze ball valve is more than just a flow control device—it is a safeguard for industries operating in some of the most hostile environments on earth. Its resistance to seawater corrosion, mechanical strength, and reliability have made it a cornerstone in marine, offshore, chemical, desalination, and power generation systems.

While initial costs may be higher than alternative materials, the long-term benefits of durability, safety, and reduced maintenance make it a cost-effective solution. As industries increasingly demand sustainable and reliable technologies, aluminum bronze ball valves are positioned to play a vital role in ensuring operational excellence for decades to come.