Valves play an indispensable role in industrial and domestic piping systems, helping to control, regulate, and direct the movement of liquids, gases, steam, and even slurries. Among the wide range of valves available, the globe valve has carved a unique position due to its reliability in flow regulation and throttling applications. Recognizable by its characteristic spherical body, the globe valve has long been a staple in industries where precise control of fluid flow is crucial.

Unlike gate valves, which are primarily suited for fully open or fully closed positions, globe valves excel at regulating flow within pipelines. This makes them an essential component in sectors such as power generation, oil and gas, water treatment, chemical processing, and HVAC systems. While they are known to generate higher pressure drops compared to other valve types, their accuracy and versatility often outweigh this drawback.

In this report, we explore the structure, working principle, purpose, and applications of globe valves, while also examining their trims, materials, and the industries that depend on them.

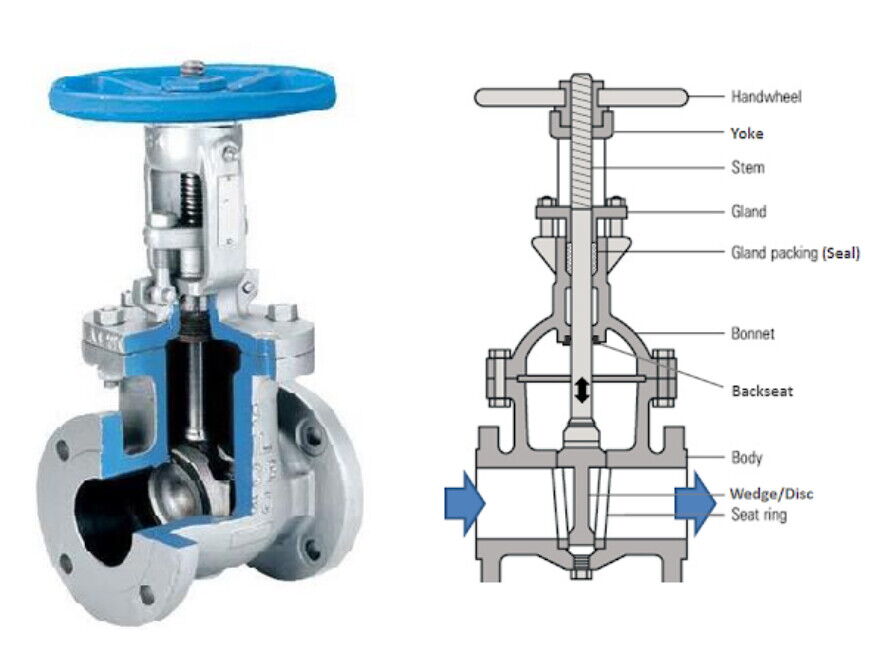

A globe valve consists of a spherical body divided into two halves by an internal baffle. At the center of the baffle sits an opening with a seat, against which a disc or plug is pressed to control the flow of fluid. This disc is connected to a stem, which in turn is operated manually (using a handwheel) or automatically (through pneumatic, electric, or hydraulic actuators).

The defining feature of a globe valve is its linear motion. As the handwheel or actuator is turned, the stem moves the disc vertically towards or away from the seat. This up-and-down motion is what allows precise regulation of the flow. Unlike quarter-turn valves such as ball or butterfly valves, which rotate to open or close, globe valves depend on this linear displacement for fine-tuned flow adjustment.

When the disc is raised, fluid passes through the gap between the disc and seat, continuing its journey through the pipeline. As the disc lowers, the available passage for flow narrows, causing resistance and restricting the amount of fluid that can pass. At full closure, the disc seals against the seat, halting flow completely.

This mechanism offers excellent throttling capabilities, making globe valves one of the most trusted solutions for flow control rather than just isolation.

To ensure a tight seal, the disc and seat are precision-engineered to match surfaces. In demanding applications, the disc may be reinforced with softer materials or hard facings such as Stellite, ensuring durability and leak resistance even under harsh operating conditions.

Like all valves, globe valves rely on several key components:

Body – The outer casing that houses the internal components and withstands pipeline pressures.

Bonnet – Attached to the body, the bonnet contains the stem, disc, and other operating parts.

Stem – A threaded shaft that connects the actuator or handwheel to the disc.

Disc (or Plug) – The moving part responsible for regulating or stopping flow.

Seat – The stationary surface against which the disc presses to achieve a seal.

Actuator/Handwheel – Provides manual or automated control of the stem movement.

Together, these components create a durable and functional valve design that has stood the test of time.

Globe Valve Trim and Its Importance

The trim refers to the internal parts of a valve that come into direct contact with the fluid, primarily the disc, seat, stem, and backseat. In globe valves, trim design and material selection are critical because of the turbulent flow path and frictional forces inside the valve.

Bronze – Often used in smaller or low-pressure globe valves, especially with iron bodies (IBBM – iron body, bronze mounted).

Stainless Steels (400-series and 300-series) – Provide strength and resistance to wear and corrosion.

Stellite – A hard-facing alloy that resists erosion and wire-drawing.

Monel and Copper-Nickel Alloys – Selected for applications involving corrosive fluids such as seawater.

Over time, the velocity and turbulence inside the valve can erode the disc and seat surfaces. This may result in wire-drawing, where a thin path is cut into the metal by fluid flow, eventually widening into significant leakage if not repaired. This is why careful trim selection is vital for extending the life of a globe valve.

Like any mechanical device, globe valves have both strengths and limitations.

Excellent throttling capability – Can finely control flow rates.

Good sealing performance – Provides tight shut-off compared to some other valve types.

Durability – Suitable for high-pressure and high-temperature services.

Bidirectional capability – Can regulate flow in either direction.

Self-cleaning action – The upward flow against the disc helps clear away dirt or debris.

High-pressure drop – The flow path changes direction, creating resistance.

Higher operating torque – More force is needed to operate compared to gate or ball valves.

More expensive – Generally costlier than simpler valve designs.

Globe valves are widely used in industries where flow regulation and throttling are more critical than minimizing pressure drop.

In fossil-fuel and nuclear power plants, globe valves are used to control feedwater, cooling water, and steam systems. Their ability to withstand high temperatures and pressures makes them indispensable.

Globe valves regulate fuel oil, cooling fluids, and chemical feed systems in both upstream and downstream operations. Offshore platforms often use globe valves with Monel trims to resist seawater corrosion.

Municipal treatment plants employ globe valves for chemical dosing, chlorine injection, and effluent control, where precise flow adjustment is essential.

Corrosive or hazardous fluids demand valves with special trim materials. Globe valves handle acids, alkalis, and solvents, ensuring safety and process efficiency.

In commercial buildings, globe valves regulate chilled water, hot water, and steam systems to maintain temperature control and energy efficiency.

While the basic design remains the same, globe valves come in different body patterns, each optimized for specific use cases:

Z-Pattern (Standard Globe Valve) – The most common type, featuring a horizontal seat with a vertical disc movement. Best for throttling.

Y-Pattern Globe Valve – Designed for applications requiring lower pressure drop, with the stem angled at about 45°.

Angle Globe Valve – Changes the direction of flow by 90°, useful in applications where piping layout requires redirection.

With the growing demand for efficiency and automation, globe valves have evolved significantly:

Actuated Globe Valves – Equipped with electric, pneumatic, or hydraulic actuators for precise and remote control.

High-Performance Trims – Advanced alloys and coatings extend service life even in extreme conditions.

Smart Valves – Integration with IoT and control systems allows real-time monitoring and predictive maintenance.

These innovations ensure that globe valves remain relevant even as industries shift towards automation and sustainability.

Globe valves, like all mechanical equipment, require regular maintenance to ensure optimal performance, reliability, and safety. Proper upkeep not only extends the service life of the valve but also prevents unexpected downtime and costly repairs in critical systems.

One of the most important aspects of globe valve maintenance is the inspection of the valve trim—which includes the disc, seat, stem, and backseat—for signs of wear, erosion, or wire-drawing. Over time, the high-velocity and turbulent flow inside the valve can gradually damage these components, resulting in leaks or reduced throttling efficiency. Regular inspection helps identify these issues early, allowing for timely repair or replacement.

Lubrication of the stem threads is also crucial. Adequate lubrication ensures smooth operation of the valve, reduces the torque required to actuate it, and prevents the stem from seizing or galling. In actuated globe valves, periodic testing of actuators—whether pneumatic, hydraulic, or electric—is necessary to confirm proper response times and reliable operation.

Additionally, the seat and disc may require replacement if leakage exceeds acceptable levels. Using the correct materials and performing precise installation during replacement is essential to maintain the valve’s sealing performance.

Routine maintenance, including cleaning, lubrication, inspection, and timely part replacement, is a small investment compared to the risks of valve failure. By implementing a structured maintenance schedule, operators can ensure that globe valves continue to perform safely and efficiently in their intended applications, minimizing downtime and preserving the integrity of the pipeline system.

Globe valves are much more than simple on/off devices. Their precision, durability, and adaptability make them one of the most important valve types in modern engineering. While they introduce higher pressure drops, their ability to finely regulate flow outweighs this disadvantage in many industries.

From power plants and chemical facilities to water treatment and HVAC systems, globe valves continue to serve as a cornerstone of fluid control technology. With modern advancements such as smart actuators and high-performance trims, their relevance in an increasingly automated world remains secure.

In short, the purpose of a globe valve is clear: to provide accurate, reliable, and controllable flow regulation, ensuring safety and efficiency across countless industrial and commercial applications.