In the realm of flow control solutions, the double eccentric butterfly valve — also widely known as a double offset butterfly valve or high-performance butterfly valve — stands out for its robust engineering and versatile application. This valve type plays an essential role across diverse industries, including water treatment plants, district heating and cooling systems, chemical processing, oil and gas distribution, and power generation facilities.

Unlike traditional concentric butterfly valves, the double eccentric design features an off-center shaft and disc arrangement, which dramatically reduces wear and tear, improves sealing performance, and extends the valve’s operational lifespan. This clever engineering advancement addresses some of the common challenges faced with standard butterfly valves, especially in demanding or high-pressure conditions.

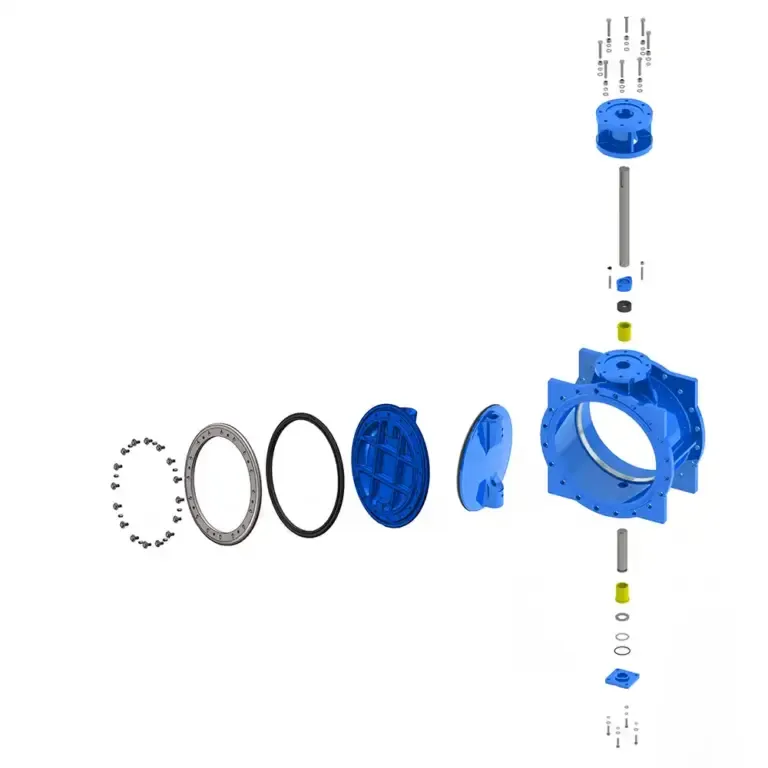

The term “double eccentric” refers to the strategic placement of two offsets within the valve’s geometry:

First Offset: The shaft is positioned behind the centerline of the sealing surface, allowing the disc to move away from the seat immediately upon opening.

Second Offset: The shaft is also offset to one side of the pipeline’s centerline, enabling the disc to swing open without friction against the seat until it reaches its final few degrees of closure.

This dual offset design drastically reduces the contact between the disc and the seat during operation, which minimizes friction, prevents unnecessary wear, and reduces torque requirements for operation. As a result, double eccentric butterfly valves deliver reliable shutoff and superior sealing capabilities, making them well-suited for high-cycle or tight shutoff applications.

One of the critical aspects of a double eccentric butterfly valve’s performance is its seat design. Different seat configurations are chosen based on the application’s demands, maintenance considerations, and fluid characteristics. Let’s explore some common seat designs:

An integrated seat consists of a machined and epoxy-coated ductile iron seat that is built directly into the valve body. This robust design provides a reliable, long-lasting sealing surface that resists wear and corrosion. Integrated seats are often used when the valve is installed in systems with stable operating conditions and where minimal maintenance is expected.

In this design, the valve features a seat ring made from durable stainless steel. The seat ring is securely fitted with an O-ring seal to prevent any leakage beneath the seat. The biggest advantage of this design is its serviceability: if the seat becomes damaged or worn, it can be easily replaced without requiring significant downtime or a full valve replacement, ensuring cost-effective maintenance.

A welded stainless steel seat provides exceptional corrosion resistance and strength. The seat is welded directly to the valve body, then machined and polished to create a perfectly smooth sealing surface. This design is ideal for applications where superior resistance to harsh media and aggressive chemicals is required.

Double eccentric butterfly valves are highly adaptable and come in a variety of configurations to meet different industrial needs. Here’s a closer look at their variations:

The standard double offset design is the most commonly used in industrial settings. These valves are engineered to minimize the friction between the disc and the seat during operation, which significantly extends their service life. They offer a lightweight, compact alternative to other valve types, such as gate or ball valves, particularly in large-diameter pipelines.

Double offset butterfly valves are suitable for regulating the flow of a wide range of liquids and gases. They can be operated manually using a hand lever or gearbox, or automated with electric, pneumatic, or hydraulic actuators for remote or high-cycle operation.

While technically a separate category, triple offset butterfly valves build on the same design principles as double eccentric valves. These tri-centric valves add a third geometric offset by angling the sealing surface of the disc. This additional offset ensures the disc contacts the seat only at the final moment of closure, delivering virtually frictionless operation.

This design makes triple offset butterfly valves ideal for high-pressure, high-temperature applications and corrosive environments, such as oil and gas pipelines, petrochemical plants, and power generation systems.

The versatility of double eccentric butterfly valves makes them a popular choice for various industries, including:

Water and Wastewater Treatment: For regulating flow in pipelines that carry clean or treated water, sewage, or slurries.

HVAC Systems: To control the flow of chilled or heated water in large commercial or industrial HVAC networks.

Chemical Processing: For handling corrosive chemicals, acids, or abrasive slurries.

Power Generation: For steam, condensate, and cooling water systems.

Oil and Gas: For upstream, midstream, and downstream flow control in pipelines carrying crude oil, natural gas, or refined products.

Marine and Shipbuilding: Due to their compact design and reliable shutoff, they are used in ballast systems, cooling water lines, and firefighting systems on ships.

Industries choose double eccentric butterfly valves for several compelling reasons:

Reduced friction between the disc and seat during operation results in less wear and tear, ensuring a longer operational lifespan compared to concentric valves.

The precise alignment of the disc and seat provides superior sealing performance, even under high pressure or temperature variations.

The double offset design minimizes the force required to operate the valve, reducing actuator size and energy consumption.

Compared to gate or globe valves of similar sizes, double eccentric butterfly valves require less installation space and support structure.

They can be configured for manual operation or automated control, offering flexibility for integration into sophisticated process control systems.

With replaceable seat options and durable construction, they deliver lower lifecycle costs.

Routine maintenance and proper troubleshooting are crucial to ensuring your double eccentric butterfly valves deliver consistent performance over many years. Here are best practices for maintaining these valves:

Observe the valve’s performance during normal operation. Unusual noises, vibrations, or difficulties in opening and closing may signal potential issues that require attention.

Periodic leak checks help verify the integrity of the valve seat and seals. Even minor leaks can escalate into significant problems if left unattended.

Inspect moving parts, seals, bearings, and the disc for signs of wear, corrosion, or damage. Timely replacement of worn components helps prevent costly failures or unexpected downtime.

Ensure that the valve’s moving parts are properly lubricated where applicable. This reduces operational torque and minimizes the risk of sticking or galling.

For complex troubleshooting or major maintenance tasks, it’s best to consult a qualified valve technician or the valve manufacturer’s service team. They can provide specialized knowledge and ensure that any repairs comply with original specifications.

Double eccentric butterfly valves have become an indispensable solution for industries seeking reliable, efficient, and cost-effective flow control. Their innovative offset design, robust seat options, and versatile configurations make them ideal for applications ranging from clean water to aggressive chemicals and high-temperature steam.

By understanding how these valves work, selecting the right design for your process, and implementing a proactive maintenance plan, you can maximize performance and extend the lifespan of your equipment — ensuring smooth, trouble-free operations for years to come.