Butterfly valves are versatile and widely used quarter-turn valves that offer effective control of fluid flow. Known for their lightweight design, small installation footprint, and cost-effectiveness, butterfly valves are ideal for both on-off and modulating services. They can be used across various industries for a wide range of applications, thanks to their ability to handle large orifice sizes while maintaining quick operational efficiency.

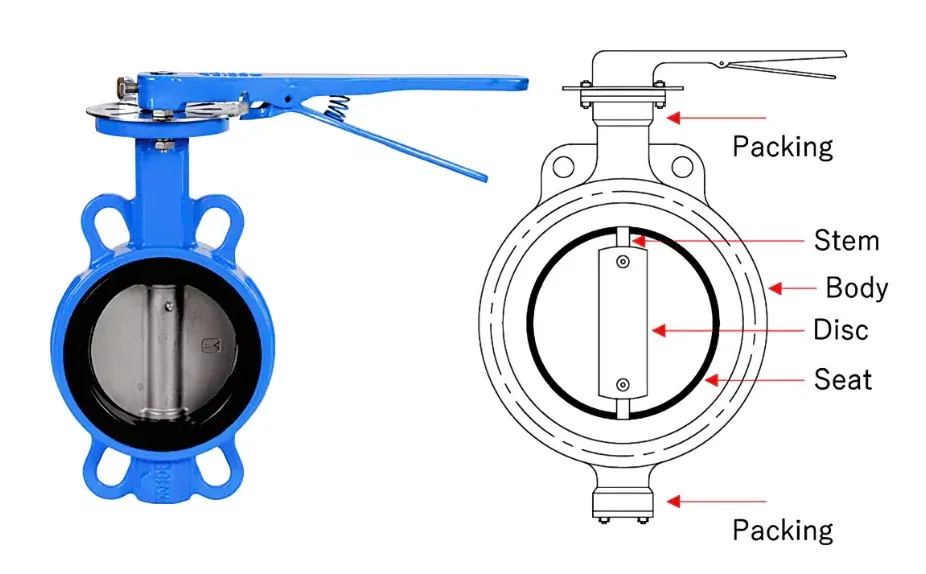

The mechanism of a butterfly valve consists of a disk, often referred to as the "butterfly," which is connected to a rod. When the valve opens, the disk rotates, allowing fluid to flow through. The valve closes when the rod rotates the disk a quarter turn to a position perpendicular to the flow direction, effectively blocking the flow.

In this article, we will explore the inner workings of butterfly valves, the different types available, various actuation options, and their diverse applications in industry.

Butterfly valves come in several distinct designs, each optimized for specific functions, pressure ranges, and application environments. The classification of butterfly valves can be based on their disc closure design, connection design, and actuation method. Understanding these categories is crucial for selecting the right valve for your specific requirements.

The disc closure design plays a significant role in the valve's performance, determining how the disc interacts with the seat and how sealing is achieved. The primary classifications of butterfly valves based on the disc closure design are concentric and eccentric.

The concentric butterfly valve is the most straightforward and commonly used design. In this configuration, the stem passes through the disc’s centerline, and the valve seat is positioned along the inside diameter periphery of the valve body. This design is known as the zero-offset valve, meaning the stem and disc are perfectly aligned at the center. The flexibility of the rubber seat is essential for creating an efficient seal.

When the valve is closed, the disc first makes contact with the seat at approximately 85° during its 90° rotation. This simple mechanism makes concentric butterfly valves suitable for low-pressure applications. Their straightforward design also contributes to cost-effectiveness and ease of maintenance, making them an ideal choice for industries where pressure is not a critical concern.

Eccentric butterfly valves differ significantly in their design. Unlike concentric valves, the stem of an eccentric butterfly valve does not pass through the centerline of the disc. Instead, it is located behind the disc, opposite the flow direction. In a single-offset eccentric valve, the stem is placed directly behind the disc’s centerline.

This unique design minimizes the amount of contact between the disc and the seat during the opening and closing process. By reducing friction and wear, eccentric butterfly valves offer extended service life and more efficient sealing. The reduced contact helps prevent seat damage, making these valves ideal for higher pressure applications where durability is crucial.

Eccentric butterfly valves can further be classified into double-offset and triple-offset designs, offering even greater advantages in terms of sealing efficiency and pressure handling capabilities. These designs are typically used in applications that require precise control and high performance under demanding conditions.

The connection design refers to how the butterfly valve is attached to the piping system. The most common connection types for butterfly valves include:

Wafer-style butterfly valves are among the most widely used due to their compact and lightweight design. These valves are sandwiched between two flanges of the piping system and are secured by bolts. The wafer design is ideal for situations where space constraints exist, offering an economical and space-saving solution.

Lug-type butterfly valves feature threaded lugs around the valve body, which allows them to be bolted directly to the pipeline without the need for additional flange connections. These valves are particularly useful in systems that require easy installation and removal or when the valve needs to be replaced without disrupting the entire pipeline.

Flanged butterfly valves have flanges on both ends of the valve body, which allows them to be bolted directly to the pipeline. This type of connection is typically used in larger, high-pressure applications where a more robust connection is necessary. The flanged connection design provides additional stability and durability for demanding environments.

The actuation method of a butterfly valve determines how the valve is operated and controlled. Butterfly valves can be actuated manually or by various types of automated systems depending on the application. The most common actuation methods include:

Manual actuation involves turning the valve by hand using a lever, gear operator, or handwheel. This method is ideal for smaller butterfly valves or applications where the valve does not need to be frequently operated. It is often used in systems where manual control is sufficient, and no automation is required.

Electric actuators are widely used in systems that require precise and remote control of the valve. These actuators convert electrical energy into mechanical motion, allowing for automatic opening and closing of the valve. Electric actuators are highly accurate and are often integrated into automated control systems for applications such as water treatment plants, HVAC systems, and industrial processes.

Pneumatic actuators use compressed air to operate the valve. Pneumatic actuators are particularly advantageous in applications where quick valve operation is required. These actuators are commonly found in industries such as pharmaceuticals, chemicals, and food processing, where precise and fast response times are crucial.

Hydraulic actuators use fluid pressure to move the valve. These actuators are used in heavy-duty applications, including oil and gas pipelines and other high-pressure environments, where the use of hydraulic power offers more force and control. Hydraulic actuators are known for their strength and ability to operate large valves in demanding conditions.

Butterfly valves are employed in a wide range of industries and applications due to their versatility and efficiency. Some of the most common uses of butterfly valves include:

Butterfly valves are often used in water treatment facilities for controlling the flow of water through various stages of the treatment process. Their quick operation and low maintenance make them ideal for regulating water flow in filtration and distribution systems.

In heating, ventilation, and air conditioning (HVAC) systems, butterfly valves are used to regulate the flow of air and fluids within the system. Their compact size and ability to handle large volumes of air or liquid make them an essential component in controlling temperature and air quality in commercial buildings.

Butterfly valves are commonly found in the chemical industry, where they are used to control the flow of various chemicals and fluids. Their ability to handle aggressive media, combined with their versatility in terms of material selection, makes them ideal for controlling the flow of corrosive substances.

The oil and gas industry often utilizes butterfly valves in pipelines, storage tanks, and refinery systems. Their reliability, ease of installation, and cost-effectiveness make them ideal for controlling the flow of oil and gas under varying pressures and temperatures.

In the food and beverage industry, butterfly valves are used for controlling the flow of liquids and gases during processing and packaging. Their hygienic design, ease of cleaning, and ability to handle both low and high viscosity fluids make them a popular choice for food processing plants.

Butterfly valves play a crucial role in many industrial applications, offering efficient, cost-effective solutions for controlling fluid flow. Their simple design, quick operation, and ability to handle a wide range of fluids and pressures make them a versatile choice for industries ranging from water treatment and HVAC systems to chemical processing and oil and gas.

Understanding the different types of butterfly valves, their actuation methods, and their applications can help engineers and plant operators make the best choices for their specific needs. Whether for low-pressure applications or high-demand environments, butterfly valves continue to prove their worth as a reliable and efficient option in fluid control.

By selecting the right type of butterfly valve and ensuring proper installation and maintenance, businesses can improve operational efficiency and reduce costs, all while ensuring the safety and reliability of their systems.