In the complex world of fluid control systems, check valves play a critical role in ensuring the safe, efficient, and unidirectional flow of media. Among these, swing check valves stand out for their simplicity, effectiveness, and widespread use across industries. Whether installed in a water treatment plant, an irrigation system, or a steam line, swing check valves provide an essential function: preventing reverse flow.

This article explores the fundamentals of swing check valves—how they work, their construction, advantages, limitations, and where they are best applied. We will also look at variations such as top-hinged and tilting disc models and share best practices for installation and maintenance.

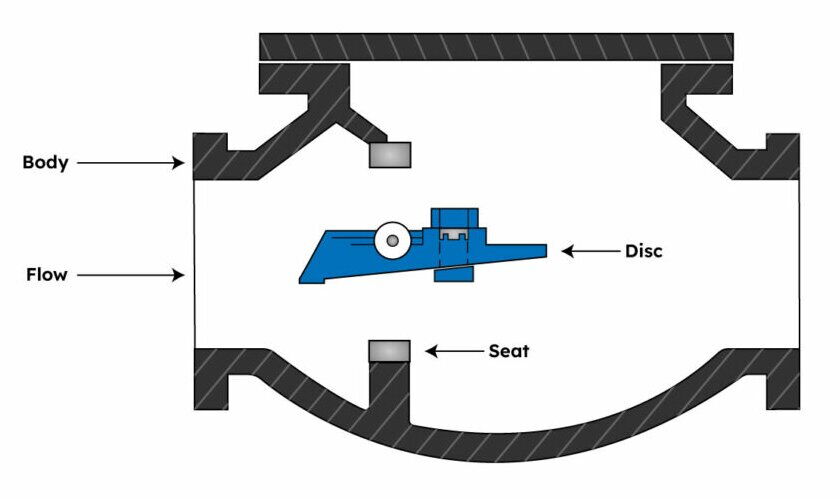

A swing check valve is a type of automatic valve designed to allow fluid to flow in one direction while preventing backflow in the opposite direction. It operates without manual or external control. The key component of the valve is a disc—often referred to as a "flap" or "clapper"—that swings on a hinge mounted at the top of the valve body.

As fluid flows through the system in the desired direction, the pressure pushes the disc open, allowing passage. When flow stops or reverses, the disc swings shut due to gravity or reverse pressure, effectively sealing the valve and stopping unwanted backflow.

The "swing" action gives the valve its name and makes it ideal for systems where preventing reverse flow is essential to protecting equipment, maintaining process efficiency, and avoiding contamination or pressure surges.

Swing check valves are available in a few common configurations, each tailored to specific flow conditions and system designs.

In the traditional top-hinged design, the disc is attached to the upper inside of the valve body. When the valve opens, the disc swings upward and rests near the valve’s top. This type is widely used due to its robust and straightforward construction. It’s suitable for most horizontal piping systems and high-flow applications.

This variant features a disc mounted on a central pivot point rather than a top hinge. The disc tilts slightly upward when cracking pressure is reached, staying in the path of the flowing fluid. The tilting mechanism allows for faster operation and lower cracking pressure—ideal in systems with lower flow rates or where rapid response is critical.

Tilting disc valves are known for their improved sealing and are often used where fluid velocity is variable or where minimizing pressure loss is essential.

Swing check valves offer several engineering and operational advantages:

Automatic Operation: No need for external actuation—flow dynamics control valve movement.

Low Pressure Drop: Minimal obstruction when open, reducing flow resistance and boosting system efficiency.

Simplicity: Fewer moving parts result in low maintenance and operational reliability.

Large Size Availability: Suitable for systems with large-diameter pipelines, especially in water and wastewater industries.

Versatility: Handles a wide range of media, including liquids, gases, steam, and slurries.

However, these advantages come with specific limitations that must be considered during design and installation.

While swing check valves are versatile, they are not suitable for every scenario:

Slow Closing Response: Due to their design, swing check valves tend to close slowly, especially in low-pressure or low-velocity systems. This lag can result in water hammer, a shockwave caused by sudden fluid stoppage, potentially damaging equipment.

Orientation Sensitivity: Swing check valves are most effective in horizontal piping. In vertical installations, flow must always move upwards to prevent gravity from holding the disc open, which would permit reverse flow.

Not Ideal for Pulsating Flow: Systems with frequent flow reversals or pulsations may cause the disc to flutter, leading to wear and noise.

Proper installation of swing check valves is critical for reliable performance and long-term durability.

Ensures the disc opens and closes freely with the flow.

Gravity and reverse pressure work together to seat the disc effectively.

Suitable for high-flow conditions and larger valve sizes.

Can be used if absolutely necessary, but only when flow direction is upward.

Disc still relies on gravity to close, but may close more slowly.

Should be avoided in vertical downward flow applications, as gravity will prevent the valve from sealing.

In vertical downward flow scenarios, an alternative valve type—such as a lift check valve or a spring-loaded inline check valve—should be selected.

Swing check valves are indispensable in many sectors due to their flexibility and reliability:

Used to prevent reverse flow and potential contamination, swing check valves are common in intake and distribution lines. Their ability to handle large-diameter piping makes them ideal for municipal water systems.

Installed on the discharge side of pumps, these valves prevent water from flowing back into the pump when it is turned off. This protects pump components from pressure shock and unnecessary cycling.

Large-scale irrigation systems rely on swing check valves to maintain directional flow over long distances. Their low-pressure drop and large size availability are well suited for the task.

In sewage and drainage systems, swing check valves manage the flow of dirty water and effluents. Their ability to operate automatically without power or manual input makes them valuable in remote or underground locations.

High-temperature steam lines often incorporate swing check valves to control condensate return flow and ensure safety in industrial boiler operations.

Swing check valves are manufactured from a wide range of materials, depending on application and media compatibility:

Cast Iron or Ductile Iron: Ideal for water and low-pressure systems.

Carbon Steel: Suitable for general-purpose industrial applications.

Stainless Steel: Corrosion-resistant and used in food, pharmaceutical, and chemical systems.

Bronze and Brass: Common in HVAC and potable water systems.

Valve sizes range from small diameters for residential or light commercial applications to large diameters (up to 48 inches or more) for municipal and industrial systems. Proper sizing is crucial to ensure adequate flow rates and pressure drops within acceptable limits.

Swing check valves are known for their low-maintenance requirements. Still, routine inspections are recommended to ensure optimal performance and avoid system issues:

Visual Inspection: Check for external leaks, corrosion, and dirt buildup.

Internal Checks: If feasible, inspect the disc and hinge for wear or debris that could prevent sealing.

Leak Testing: Periodic pressure tests can identify sealing failures early.

It's important to ensure that the valve seat and disc remain clean and undamaged to avoid backflow, especially in systems where contamination or fluid reversal poses a risk to downstream equipment.

One of the most discussed challenges with swing check valves is water hammer, particularly in high-velocity or long piping systems. Engineers often employ the following strategies to mitigate this risk:

Use of Dampers or Dashpots: These slow the disc’s movement and reduce shock upon closing.

Spring-Assisted Swing Checks: Incorporating a spring to assist with faster closure can significantly reduce slam and water hammer.

Surge Tanks or Arrestors: These can absorb the shock waves created by sudden valve closures.

For critical systems, consulting with valve manufacturers on custom solutions may be necessary to ensure safety and durability.

Swing check valves remain a cornerstone of fluid control technology, delivering reliable one-way flow protection across a broad spectrum of industries. Their automatic, energy-free operation, combined with their ability to handle large flow volumes, makes them especially valuable in water, wastewater, and industrial systems.

While they are not suited for every scenario—particularly where vertical downward flow or rapid closure is required—their simplicity, durability, and cost-effectiveness make them a go-to solution in many piping designs.

By understanding how swing check valves work, where they excel, and how to install and maintain them properly, engineers and operators can ensure safer and more efficient fluid systems.