Check valves—also known as one-way or non-return valves—are essential components in fluid systems across a wide spectrum of industries. From oil and gas to water treatment, HVAC systems to power generation, check valves play a crucial role in ensuring that fluids or gases flow in one direction only. By preventing reverse flow, they help protect upstream equipment, maintain pressure, and support efficient system performance.

Check valves are automatic devices that allow fluid (liquid or gas) to flow through them in only one direction. They operate without external actuation—relying instead on the flow pressure of the fluid itself. When the flow ceases or reverses, the valve automatically closes, preventing any backflow.

Backflow can be hazardous and costly. In water supply systems, it can lead to contamination. In oil and gas pipelines, it can damage pumps, compressors, and other sensitive equipment. That’s why check valves are indispensable in any process where reverse flow is a risk.

Protection of Equipment: They safeguard pumps, compressors, and other machinery from damage due to reverse flow.

Process Efficiency: By maintaining directional flow, they help systems operate more reliably and efficiently.

Low Maintenance: Most check valves are self-operating and require little to no external controls.

Versatile Application: Available in a range of sizes and materials, they are suitable for nearly every industrial sector.

There are several types of check valves, each designed to meet specific application needs. Choosing the right type depends on factors such as pressure, flow rate, the nature of the fluid, installation orientation, and maintenance preferences.

Below, we explore the most commonly used types of check valves, along with their working principles and typical applications.

Swing check valves are among the most widely used types due to their simple design and effective performance in horizontal piping systems.

How They Work:

These valves use a hinged disc or flapper that swings open with forward flow and swings shut when flow reverses. The flow pushes the disc away from the valve seat, and when the flow stops or reverses, gravity or backpressure causes the disc to return to the closed position.

Key Features:

Full-port design allows for minimal pressure drop.

Best suited for horizontal installations.

Ideal for low-velocity, high-volume flow applications.

Common Applications:

Oil and gas pipelines

Water and wastewater systems

Power plants

Swing check valves are particularly effective in systems with infrequent flow reversals. Because of their large travel distance, they may not be suitable for high-speed applications where rapid closure is required.

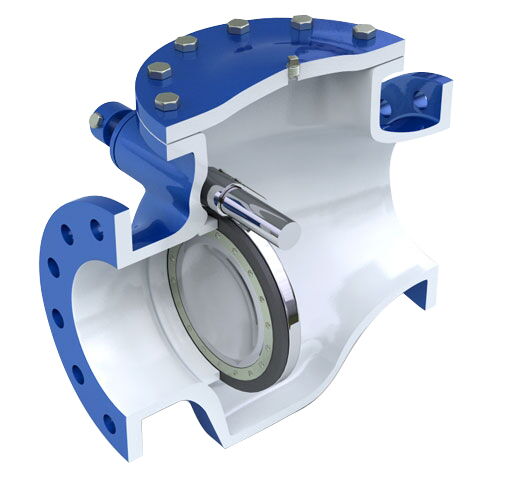

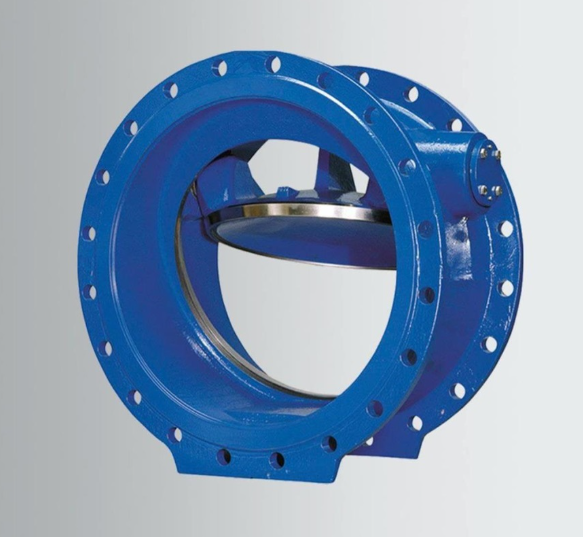

A tilting disc check valve is a modified version of the swing check valve, engineered for improved performance and responsiveness.

How They Work:

Instead of a fully swinging disc, the tilting disc pivots around a point near its center. This allows the disc to “tilt” open and close with a shorter stroke, enabling faster response and reduced water hammer.

Key Features:

Reduced pressure drop and quick closing action.

Effective in both horizontal and vertical piping.

Smooth operation in systems with pulsating or turbulent flow.

Common Applications:

High-pressure steam systems

Condensate return lines

Refining and chemical processing plants

Tilting disc check valves are especially useful in scenarios with frequent flow reversals, offering durability and minimal wear over time.

Ball check valves are simple, compact, and reliable—particularly for low-pressure systems or those handling slurries or viscous fluids.

How They Work:

A rubber or metal ball sits in a conical seat inside the valve. As fluid flows in the correct direction, it lifts the ball out of the seat and allows flow through the valve. When the flow stops or reverses, gravity or backpressure pushes the ball back into the seat to block the flow.

Key Features:

Minimal moving parts; highly durable.

Self-cleaning design in some models.

Can be spring-loaded for faster response.

Common Applications:

Wastewater systems

Mining and slurry pipelines

Food and beverage processing

These valves are especially valued for their simplicity and resistance to clogging, making them ideal for dirty or particulate-laden fluids.

Also called wafer check valves, these compact devices are designed to save space while maintaining reliable one-way flow control.

How They Work:

Dual plate check valves use two semi-circular plates that are hinged in the center. When flow is forward, the plates swing open; when it reverses, the plates snap shut with the help of a spring.

Key Features:

Lightweight and space-saving.

Fast-acting closure reduces water hammer.

Low pressure drop due to streamlined flow path.

Common Applications:

Marine and offshore installations

Firefighting systems

HVAC systems

Because of their compact wafer-style design, they can be easily installed between flanges in tight spaces.

Lift check valves are commonly used in high-pressure applications and systems where precise sealing is critical.

How They Work:

A disc or piston sits on a seating surface. Forward flow lifts the disc off the seat, and when flow reverses or stops, gravity or spring pressure causes the disc to fall back onto the seat, sealing the flow path.

Key Features:

Excellent leak-tight performance.

Best suited for vertical flow applications.

Available in metal-seated designs for high-temperature use.

Common Applications:

Steam lines

Boiler feedwater systems

High-pressure gas and oil pipelines

Lift check valves require clean flow and are typically not suitable for slurries or debris-filled fluids.

Silent check valves—also known as spring-assisted check valves—are designed to minimize noise and vibration in piping systems.

How They Work:

They use a spring to close the valve before flow reversal occurs, eliminating the slamming sound often associated with conventional check valves. These valves are usually installed in vertical positions.

Key Features:

Quiet operation.

No slamming or water hammer.

Rapid response time.

Common Applications:

High-rise building water systems

Clean water pumping stations

Pharmaceutical and food-grade piping systems

These valves are ideal in any application where noise reduction is a concern.

Choosing the right check valve for your application involves evaluating several key factors:

Flow Rate: Consider the flow velocity and pressure conditions.

Fluid Characteristics: Is the fluid clean, corrosive, viscous, or carrying solids?

Installation Orientation: Horizontal or vertical? Not all valves are suitable for both.

Maintenance Access: Some valves require easier access for servicing than others.

Size and Space Constraints: Wafer-style and compact valves are better for tight areas.

Closing Speed and Water Hammer: In sensitive systems, silent or spring-loaded valves may be preferable.

It’s often helpful to consult with valve manufacturers or engineers to ensure compatibility with system design and operational goals.

Check valves come in a variety of materials to suit different applications and environments:

Carbon Steel and Stainless Steel: Popular in oil, gas, and chemical industries.

Bronze and Brass: Used in potable water systems and marine applications.

Ductile Iron: Common in municipal and water treatment systems.

PVC or CPVC: Used in corrosive or lightweight fluid systems.

The choice of material impacts corrosion resistance, temperature tolerance, and mechanical durability.

While check valves are designed for longevity and minimal maintenance, regular inspections can help ensure consistent performance:

Listen for Unusual Noises: Slamming or chattering can signal wear or improper installation.

Inspect Sealing Surfaces: Leaks often stem from worn or damaged seats.

Check for Clogging: Debris can get lodged in the valve, especially in slurry or wastewater applications.

Test Spring Tension (for spring-loaded valves): A weak spring can affect closing efficiency.

Replacing or cleaning components early can prevent costly system downtime or equipment damage.

Check valves may be simple in design, but their function is vital in maintaining safe and efficient fluid systems. Whether in an industrial, commercial, or municipal setting, choosing the right type of check valve ensures one-way flow, prevents backflow damage, and supports optimal system operation.

From swing and ball types to silent and dual plate varieties, the check valve landscape offers a solution for nearly every fluid handling challenge. Understanding the key features and differences between types helps engineers, facility managers, and technicians make informed choices tailored to their specific applications.