In the world of industrial valves, trunnion ball valves have emerged as a superior choice for controlling the flow of media in pipelines, especially in high-pressure and critical applications. Unlike the more common floating ball valves, trunnion ball valves feature a unique design that ensures enhanced stability, durability, and performance. These valves are widely used in industries such as oil and gas, petrochemicals, water treatment, and power generation, where reliability, safety, and efficiency are non-negotiable. This article delves into the design, advantages, applications, and selection criteria of trunnion ball valves, providing a comprehensive understanding of why they are a preferred choice for demanding environments.

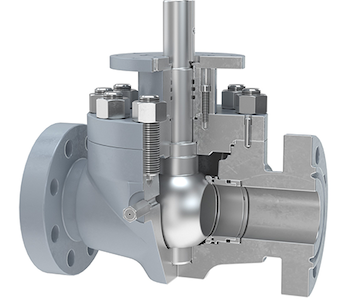

Trunnion ball valves are quarter-turn valves designed to regulate the flow of liquids, gases, and other media in pipelines. What sets them apart from floating ball valves is their unique mechanical configuration. In a trunnion ball valve, the ball is anchored on both ends: one end is connected to the stem, while the other is supported by a shaft called the trunnion. This dual anchoring system ensures that the ball remains firmly in place, even under high-pressure conditions. In contrast, floating ball valves rely solely on the stem to hold the ball in position, allowing it to "float" slightly within the valve body.

The trunnion design provides several key benefits, including improved sealing, reduced wear and tear, and the ability to handle higher pressures. These features make trunnion ball valves ideal for applications where safety, reliability, and performance are critical.

Trunnion ball valves offer a host of advantages that make them a preferred choice for industrial applications. Here are some of the key benefits:

One of the most significant advantages of trunnion ball valves is their ability to handle extremely high pressures. The trunnion design distributes the load evenly across the ball and the valve body, reducing stress on the sealing components. This makes them suitable for high-pressure applications where floating ball valves would fail.

Trunnion ball valves are known for their positive sealing mechanism, which ensures a leak-proof closure. This is particularly important in applications involving hazardous or environmentally sensitive media, where even a minor leak could have serious consequences.

Constructed from high-quality materials such as stainless steel, carbon steel, and alloys, trunnion ball valves are built to withstand harsh operating conditions. Their robust design minimizes wear and tear, ensuring a long service life with minimal downtime.

Thanks to their simple yet effective design, trunnion ball valves require minimal maintenance. High-quality components and precision engineering reduce the need for frequent repairs, lowering operational costs over time.

The quarter-turn operation of trunnion ball valves allows for rapid opening and closing, making them ideal for emergency shut-off situations. This feature is particularly valuable in industries where quick response times are critical to safety.

Trunnion ball valves are available in a wide range of sizes, materials, and configurations, making them suitable for diverse applications. Whether you need a valve for high-temperature steam, corrosive chemicals, or high-pressure gas, there is a trunnion ball valve designed to meet your requirements.

In certain applications, such as pipeline maintenance or equipment isolation, it is essential to ensure complete isolation of the process fluid. This is where trunnion double block and bleed (DBB) ball valves come into play. A DBB system provides an additional layer of safety by isolating the working area on both the upstream and downstream sides of the valve.

Here’s how it works:

Two trunnion ball valves act as block valves, shutting off the flow on either side of the working area.

A bleed valve (typically a ball or needle valve) is used to vent any residual pressure trapped between the two block valves.

The vented fluid is directed to a safe location, in compliance with environmental regulations.

This configuration ensures that the process fluid is completely isolated from other equipment, reducing the risk of leaks or contamination. DBB systems are commonly used in the oil and gas industry, where safety and environmental protection are paramount.

Selecting the right trunnion ball valve for your application requires careful consideration of several factors. Here are some key points to keep in mind:

Identify the specific application and the characteristics of the fluid being handled. Consider factors such as pressure, temperature, viscosity, and corrosivity. For example, a valve used in a high-temperature steam application will have different requirements than one used for corrosive chemicals.

Choose a valve with a pressure rating that exceeds the maximum operating pressure in your system. This ensures that the valve can handle unexpected pressure surges without compromising performance or safety.

The materials used in the valve must be compatible with the fluid being handled. For corrosive media, materials such as stainless steel or exotic alloys may be required. For high-temperature applications, materials with excellent thermal resistance are essential.

Consider the available space and piping layout when selecting the valve size. For overhead installations, the weight of the valve may also be a factor. Ensure that the valve can be easily integrated into your existing system.

Ensure that the valve complies with relevant industry standards and safety regulations. This is particularly important in industries such as oil and gas, where compliance with standards like API, ASME, and ISO is mandatory.

Choose a reputable manufacturer known for producing high-quality valves and providing reliable after-sales support. A well-established manufacturer will offer warranties, technical assistance, and spare parts, ensuring long-term reliability.

Trunnion ball valves are used in a wide range of industries and applications, including:

Oil and Gas: For pipeline transportation, refining, and offshore drilling.

Petrochemicals: For handling corrosive and hazardous chemicals.

Power Generation: For controlling steam, water, and other media in power plants.

Water Treatment: For managing the flow of water and wastewater.

Mining: For slurry and abrasive media handling.

Their ability to handle high pressures, provide reliable shut-off, and operate in harsh environments makes them indispensable in these industries.

Trunnion ball valves represent a significant advancement in valve technology, offering unparalleled performance, reliability, and safety. Their unique design, combined with their ability to handle high pressures and provide leak-proof sealing, makes them an ideal choice for demanding industrial applications. Whether you need a standard trunnion ball valve or a specialized double block and bleed configuration, these valves deliver the performance and durability required to meet the challenges of modern industry.

As industries continue to evolve and demand higher standards of safety and efficiency, trunnion ball valves will remain at the forefront of flow control solutions. By understanding their advantages, applications, and selection criteria, you can make informed decisions that enhance the performance and reliability of your systems. With the right trunnion ball valve, you can ensure seamless operation, reduce maintenance costs, and achieve long-term success in your industrial processes.