A triple eccentric butterfly valve is widely used in industrial applications due to its unique design, excellent sealing, and durability. The name "triple eccentric butterfly valve" derives from the threefold eccentric design involving the valve body, valve disc, and valve seat. This design effectively reduces wear and enhances the sealing effect, making it particularly suitable for high-temperature and high-pressure environments.

Design features

The design features of the triple eccentric butterfly valve are mainly reflected in the following aspects:

(1) Triple eccentricity

Single eccentricity: The center of the valve shaft deviates from the center line of the valve body sealing surface.

Double eccentricity: The center of the valve disc sealing surface deviates from the center line of the valve body.

Triple eccentricity: The sealing surface is conical, causing the seal to form radial compression along the valve seat when closing. This triple eccentric design ensures that the sealing surface does not rub during the closing process, greatly extending the service life of the valve.

(2) Metal seat

Triple eccentric butterfly valves usually adopt a metal seal structure, enabling them to maintain good sealing performance in high-temperature and high-pressure environments. Compared with traditional soft seated valves, metal seated valves have better wear resistance and corrosion resistance.

(3) Low torque

The triple eccentric design reduces the contact of the sealing surfaces during valve operation, resulting in lower required torque. This not only makes operation more convenient but also reduces the power requirements for the actuator.

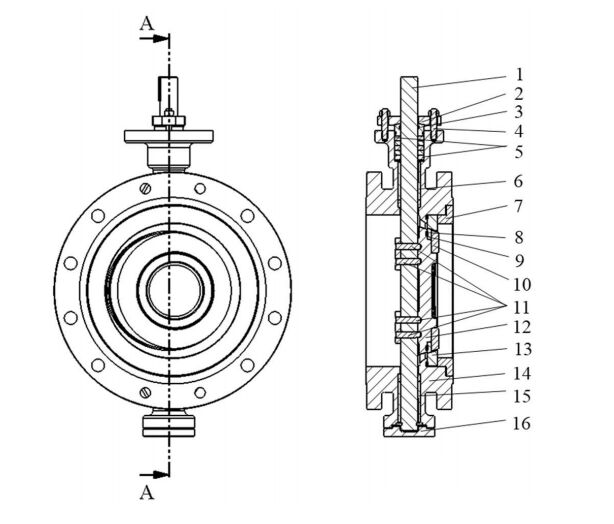

The triple eccentric butterfly valve consists of valve bodies, valve plates, valve plate glands, valve seats, valve stems, conical pins, bushing, packing, and sealing rings, as shown in Figure 1. The rib plate is installed on the back of the valve plate, providing good rigidity and small deformation. The valve stem adopts a through shaft, with the valve stem and valve plate connected with zero clearance through an eccentric sleeve, positioned and fixed with a conical pin. The sealing ring and valve seat are both made from stainless steel, allowing them to work in high-temperature, high-pressure and highly-corrosive environments. Due to its small deformation, it can achieve no internal leakage under positive or reverse pressure.

1. Stems 2. Pressure plates 3. Packing glands 4. Studs 5. Packing 6. upper bushing 7. Seat glands 8. Seal rings 9. Valve plate gaskets 10. Valve plate glands 11. Conical pins 12. Valve plates 13. Valve seats 14. Valve bodies 15. Lower bushing 16. Glands

Figure 1 The structure diagram of triple eccentric butterfly valves

The triple eccentric butterfly valve plate moves within the angle of 0° to 90° by controlling the rotation of the valve stem and plate sealing part through the torque of the driving device. When the valve is about to open, the sealing surface of the valve plate sealing part instantly detach from the valve seat surface. When the valve is closing, the sealing ring of the butterfly plate contacts the sealing surface between the valve seat, generating elastic deformation to achieve sealing.

Selection of actuators for triple eccentric butterfly valves

Actuators are devices that use electrical energy, fluid sources or control signals to achieve linear or rotary motion. According to the different power sources, they are usually divided into electric, pneumatic and hydraulic actuators. Selecting the right actuator can quickly open or close the valve in emergency situations, preventing the further spread of danger and minimize plant losses. Additionally, according to the driving method, actuators can be divided into multi-turn, single-turn or linear actuators. In this context, the triple eccentric butterfly valve uses a single-turn actuator, allowing the valve plate to rotate 90° to achieve full opening or closing.

Applications

Triple eccentric butterfly valves are widely used in the petroleum, natural gas industry, chemical, pharmaceutical, electric power and metallurgical industries due to their unique design and excellent performance.

Advantages

Compared with other valves, triple eccentric butterfly valves have excellent sealing performance, high-temperature and high-pressure resistance, as well as a long service life. Due to the triple eccentric design, the sealing surface is wear-free, providing superior and long-lasting sealing performance. The metal sealing structure enables the triple eccentric butterfly valve to work stably in high-temperature and high-pressure environments. The frictionless sealing structure and high-strength materials significantly extend the valve's service life.

Conclusion

The triple eccentric butterfly valve performs well under various harsh working conditions due to its unique design and excellent performance, and is widely used in the petroleum, chemical, power, and other industries. Its excellent sealing performance, high-temperature and high-pressure resistance and long service life make it an indispensable and important valve in modern industry. In the future, with the continuous advancement of technology, the application prospects of the triple eccentric butterfly valve will be broader.