Threaded gate valves play a pivotal role in numerous industrial and commercial applications. These valves are widely used to start or stop the flow of fluids in pipelines, offering versatility and reliability across different pressure and temperature conditions. Their compact design, ease of installation, and low cost make them an ideal solution for small to medium-sized piping systems.

Though gate valves are primarily designed for isolation purposes rather than regulation, threaded variants can be useful in applications where minimal throttling is required. Choosing the right threaded gate valve involves understanding its construction materials, stem type, sealing method, and compatibility with specific fluids or gases. This article provides a comprehensive overview of threaded gate valves—their working principles, structural features, types, and common uses in various sectors.

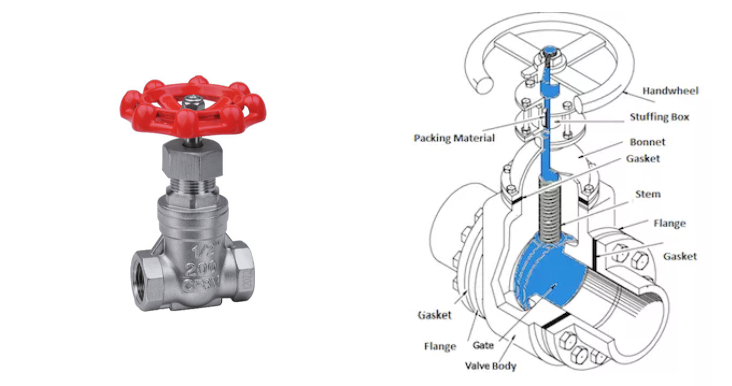

A threaded gate valve is a type of shut-off valve that opens by lifting a gate out of the path of the fluid. It features threaded ends that allow it to be connected directly to a pipeline using matching male or female pipe threads. This connection method makes installation straightforward and cost-effective, particularly in systems where welding or flanging is not feasible.

Threaded gate valves are suitable for a range of flow media—including water, oil, gas, and steam—and are found in everything from water treatment systems to petrochemical facilities. They are designed to handle both low-pressure and high-pressure environments, and can function well under moderate temperatures. These valves are commonly stocked in hardware outlets, but industrial-grade versions are also manufactured for more demanding operations.

The body material of a threaded gate valve significantly impacts its performance and longevity. Most commonly, these valves are made from:

Cast Iron: Suitable for non-corrosive fluids and general-purpose applications.

Ductile Iron: Offers better strength and toughness than cast iron, making it ideal for higher pressure environments.

Gunmetal and Bronze: Preferred in marine and corrosive environments due to their resistance to saltwater.

Stainless Steel: Excellent for handling corrosive media and high temperatures.

For each application, selecting the correct material is critical to ensure corrosion resistance, structural integrity, and optimal sealing performance.

The typical structure of a threaded gate valve includes:

Bonnet: The cover of the valve body that houses the stem and seals.

Seat Ring: The sealing surface against which the gate closes. It can be integrally cast with the valve body or welded in place.

Gate/Disc: The main closing element that moves up or down to allow or block flow.

Stem: The component that transmits motion from the handwheel or actuator to the gate.

Threaded gate valves are designed for tight shutoff and are generally not used for precise flow control due to potential damage caused by partially open discs under high flow velocity.

Threaded gate valves are manufactured in two basic stem configurations:

Non-Rising Stem: In this design, the stem rotates to raise or lower the gate but remains stationary in vertical position. The threads are inside the valve body. Non-rising stems are compact and ideal for limited-space installations, though they offer no visual indication of valve position.

Rising Stem: The stem moves vertically along with the gate, providing a clear visual cue of whether the valve is open or closed. The threads are external, which keeps them away from the fluid and makes lubrication easier. However, this type requires more installation space.

Threaded gate valves are typically operated manually through a handwheel. Their slow opening and closing action prevents water hammer—a sudden pressure surge in pipelines—making them safe for many fluid systems. Moreover, because the flow path inside a gate valve is straight and unrestricted when open, flow resistance remains low. This design minimizes energy loss across the valve and contributes to efficient system operation.

However, threaded gate valves are not without limitations. They can be challenging to operate under vibration-prone conditions and may require regular maintenance for smooth performance. In some cases, debris can accumulate in the valve seat or packing area, especially in systems lacking filtration.

Threaded gate valves offer several notable benefits, particularly in industrial settings where compact size and budget-friendly solutions are essential:

The straight-through design of the gate path allows media to flow with minimal turbulence and pressure drop.

Since pressure on both sides of the disc is balanced, opening and closing the valve requires relatively low torque, reducing wear and tear on the stem and seating surfaces.

The gradual movement of the gate makes pressure surges less likely during shutoff.

Threaded connections eliminate the need for flanges or welding, resulting in faster, more cost-efficient installation—especially for small-diameter pipelines.

Suitable for a wide range of media, including water, oil, gas, steam, and some corrosive chemicals.

With fewer moving parts compared to more complex valves, maintenance is often straightforward, and downtime is reduced.

Due to their robust design and dependable sealing performance, threaded gate valves are used in a wide array of industries and service conditions. Some common application areas include:

Used for isolating sections of water distribution pipelines, threaded gate valves ensure reliable shutoff in municipal and residential systems.

Threaded gate valves are extensively used in upstream and midstream operations, particularly in small-diameter pipe segments at drilling sites and distribution points.

The valves handle process media, including hydrocarbons and steam, where moderate temperature and pressure control is necessary.

In heating, ventilation, and air conditioning setups, these valves assist in isolating system components for maintenance or system modification.

From compressed air lines to non-corrosive chemical processing, threaded gate valves are favored for their durability and minimal leakage.

Before selecting a threaded gate valve for a specific application, several important factors must be evaluated:

Media Compatibility: Ensure that the internal materials (seat, gate, body) are chemically compatible with the fluid or gas to be controlled.

Pressure and Temperature Ratings: Verify the valve’s specifications meet or exceed system demands.

Stem Type: Consider available space and the need for visual position indicators when deciding between rising and non-rising stems.

Valve Size: Threaded gate valves are typically used in systems with smaller diameters (usually up to 4 inches), as larger valves tend to require flanged or welded connections for better mechanical support.

Maintenance Access: Choose a design that allows for easy disassembly and repair in case of seat wear or packing leaks.

Despite their advantages, threaded gate valves are not suitable for every application. Key limitations include:

Limited Throttling Capability: Using a gate valve to regulate flow can cause vibration, noise, and premature wear of the seating surfaces.

Thread Wear: Frequent installation or disassembly can wear out threads, especially in softer metals like brass.

Seal Sensitivity: Dirt and particulates in the system can affect seal integrity if filtration is inadequate.

In environments with constant vibration, high flow velocity, or complex control needs, alternate valve types like globe valves, ball valves, or butterfly valves may offer better performance.

Threaded gate valves remain an essential component in piping systems requiring reliable shutoff, especially where compact installation and cost efficiency are priorities. Their simple yet effective design makes them suitable for a wide variety of services—from water and gas distribution to industrial fluid management.

As with any valve selection, understanding the specific system requirements and matching them to the valve’s construction and capabilities is crucial. When properly chosen and maintained, a threaded gate valve offers long-lasting performance, safe operation, and a dependable solution for flow isolation in numerous industrial settings.