Butterfly valves are one of the most widely used flow-control components in modern piping systems. Known for their compact structure, fast operation, and cost-effective design, these valves are widely applied in industries such as water treatment, HVAC, chemical processing, power generation, food and beverage, and general industrial systems. Because they frequently interface with flanges, pipes, and other system components, a common question arises during installation:

The answer is not universal—it depends on the valve type, connection style, flange standard, and application environment. In some cases, butterfly valves do not need external gaskets because their elastomeric seats already function as sealing elements. In other cases—particularly in high-temperature or high-pressure systems—external gaskets become essential to ensure long-term sealing reliability. This article explores the mechanics of gaskets, analyzes when they are required for butterfly valves, discusses valve-specific considerations, and offers selection guidelines for installers and engineers.

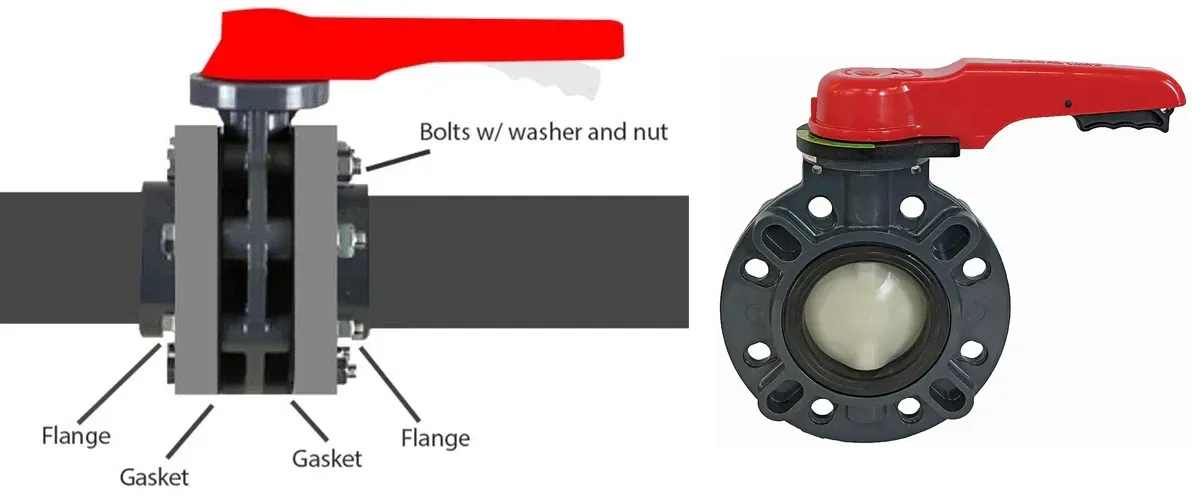

A gasket is a compressible sealing material placed between two mating surfaces to prevent the escape of liquids or gases. Despite appearing simple, gaskets play a critical role in piping safety and reliability, particularly where leakage could cause equipment failure, environmental contamination, or safety hazards.

A gasket performs several specific functions:

Fills microscopic gaps between flange surfaces

Compensates for surface irregularities, scratches, or non-parallel contact surfaces

Provides sealing under compression, preventing fluid or gas leakage

Absorbs vibration and thermal expansion, maintaining structural integrity

Enhances connection stability, especially under dynamic pressure changes

These functions are essential in pipeline systems where the mating surfaces of flanges, valves, or pumps are not perfectly smooth.

A high-quality gasket must have:

Elasticity: to conform to uneven surfaces

Compressibility: to deform under bolt load without breaking

Chemical resistance: to withstand media such as acids, alkalis, oils, or solvents

Temperature resistance: to perform safely under high or low temperatures

Structural stability: to maintain sealing performance over time

Common gasket materials include rubber, PTFE, graphite, non-asbestos composites, and metal composites. The selection depends on the application’s pressure, temperature, fluid characteristics, and flange specifications.

Whether a butterfly valve needs gaskets depends primarily on the connection type and seat design.

Butterfly valves typically come in two major styles:

Wafer butterfly valves

Lug butterfly valves

Both types can be used with or without gaskets, depending on the valve seat type and flange standard.

Most soft-seated butterfly valves—such as EPDM-lined, NBR-lined, PTFE-lined, or rubber-lined designs—do not require additional gaskets. Why? Because the valve seat itself functions as the sealing element against the flange faces.

These seats extend slightly outward, forming a built-in gasket. When the bolts are tightened, the seat compresses between the valve body and flanges to form a leak-tight seal.

This design is typical for:

Water distribution systems

HVAC systems

Irrigation lines

Low-pressure and medium-pressure industrial pipelines

Key advantage: Eliminating external gaskets simplifies installation and reduces maintenance costs.

Gaskets may be needed when:

The valve has a metal seat, such as stainless steel, bronze, or alloy seats

The system operates at high temperature, where elastomer seats may degrade

The valve is used in high-pressure or vacuum environments

The flange type requires specific gasket compatibility

The media is highly corrosive, requiring PTFE or graphene-based gaskets

The valve is installed on lined, raised-face, or ring-joint flanges

In these environments, relying solely on the butterfly valve’s seat is insufficient.

Gaskets act as a secondary seal to ensure long-term performance and prevent leakage under extreme conditions.

Selecting the right gasket for butterfly valves is essential for maintaining sealing performance, system safety, and long-term operating efficiency. Because butterfly valves operate with a rotating disc, the gasket must accommodate the spacing and alignment needed for disc movement.

Several key requirements exist:

The gasket must be chemically compatible with:

The fluid medium

The valve seat material

The pipe or flange material

Chemical incompatibility can cause swelling, hardening, or deterioration of the gasket.

Butterfly valves face varying pressure loads depending on their duty. A gasket must be able to withstand:

Continuous pressure

Pressure surges

Vacuum conditions

High temperatures (steam, hot oil, chemicals)

For example, rubber gaskets work well for water or air but degrade under hot hydrocarbons. Graphite gaskets perform well in high-temperature environments exceeding 500°C.

Flange surfaces often exhibit:

Scratches

Corrosion

Uneven machining

Slight misalignment

A gasket must absorb these irregularities through compressive deformation.

Butterfly valves generate dynamic forces as the disc rotates. A suitable gasket should resist:

Vibrations

Bolt load fluctuations

Pressure cycling

Mechanical stress from repeated operation

Gasket thickness influences sealing performance:

Too thin: cannot fill surface irregularities

Too thick: excessive compression may push material into the flow path

Correct compression also ensures the butterfly valve disc has adequate clearance.

When gaskets are required, several material options can be used depending on system conditions.

Common materials include:

EPDM (excellent for water systems, resistant to heat and ozone)

NBR (good for oils and fuels)

FKM/Viton (resistant to chemicals and high temperatures)

Rubber gaskets offer excellent flexibility and sealing capability for low-pressure or medium-pressure systems. They are widely used for HVAC, water, wastewater, and industrial pipeline applications.

PTFE (Teflon) gaskets are ideal for:

Strong acids

Strong alkalis

Aggressive solvents

Corrosive chemicals

PTFE has outstanding chemical resistance, low friction, and high insulation properties, making it a go-to option in chemical processing and pharmaceutical systems.

These are eco-friendly replacements for asbestos gaskets.

Characteristics:

High tensile strength

Excellent sealing for water, gas, and oil

Good medium-temperature, medium-pressure performance

They are commonly used in oil refineries, power plants, and general industrial pipelines.

Flexible graphite offers:

Exceptional thermal stability

High compressibility

Resistance to corrosive chemicals

Performance in high-temperature, high-pressure environments

Suitable for steam lines, refinery units, and heat exchangers.

Examples include:

Spiral wound gaskets

Metal-jacketed gaskets

Graphite-filled metal gaskets

These gaskets are used for:

High-pressure pipelines

High vibration environments

Elevated temperatures

Chemical processing plants

They combine strength with elasticity, making them ideal for demanding applications.

Selecting the correct gasket requires careful evaluation of application conditions. Below are the most important considerations.

The gasket must resist the chemical composition of the fluid. Failure to ensure compatibility leads to:

Swelling

Cracking

Decomposition

Loss of sealing integrity

Temperatures may range from sub-zero to above 600°C, depending on the industry. PTFE, graphite, and metal composites are suitable for high-temperature environments.

Higher pressures require reinforced or metallic gaskets to maintain sealing integrity.

Different flange types require different gasket profiles:

Flat-face flanges: soft gaskets

Raised-face flanges: standard gaskets

Lined flanges: PTFE-lined gaskets

Ring-joint flanges: metallic RTJ gaskets

A gasket must not obstruct the rotation of the disc. Thick or improperly sized gaskets may reduce internal clearance and cause disc interference.

Consider whether the environment includes:

UV exposure

Ozone

Corrosive atmosphere

High vibration

Each condition influences material selection.

No. Different butterfly valve designs have different sealing requirements.

Usually do not need gaskets when soft-seated

Often installed with flange bolts passing through the valve body

The seat functions as the seal

May or may not need gaskets depending on seat type

Used in dead-end service and isolation applications

Triple offset valves (TOV) use metal seats for high-temperature and high-pressure systems. They require metallic or graphite gaskets to achieve reliable sealing.

Used for industrial steam, chemical, and oil applications. These valves may require PTFE or graphite gaskets depending on pressure and temperature.

So, do butterfly valves need gaskets?

The answer depends on the specific valve design, operating conditions, and seat material.

Soft-seated wafer and lug butterfly valves typically do not require additional gaskets because the integrated elastomeric seat already provides effective sealing.

High-performance, metal-seated, and triple-offset butterfly valves, as well as valves used in high-pressure, high-temperature, or corrosive environments, do require appropriate gaskets to ensure long-term sealing performance.

Selecting the right gasket ensures:

Leak-free operation

Longer service life

Reduced maintenance

Improved system safety

By understanding the relationship between butterfly valves and gaskets, engineers, installers, and maintenance personnel can ensure optimal performance and reliability across a wide range of industrial applications.