Top entry ball valves play a critical role in the modern industrial valve market. Recognized for their compact structure, high reliability, and ease of maintenance, these valves are widely used in industries such as oil and gas, petrochemical, power generation, water treatment, and more. While there are various styles of ball valves—including side entry and split body designs—top entry ball valves have carved out a strong reputation for their practicality, especially in systems where maintenance and operational reliability are key considerations.

This article delves into everything you need to know about top entry ball valves, from their working principles and structural design to their unique benefits, types, and typical industrial applications.

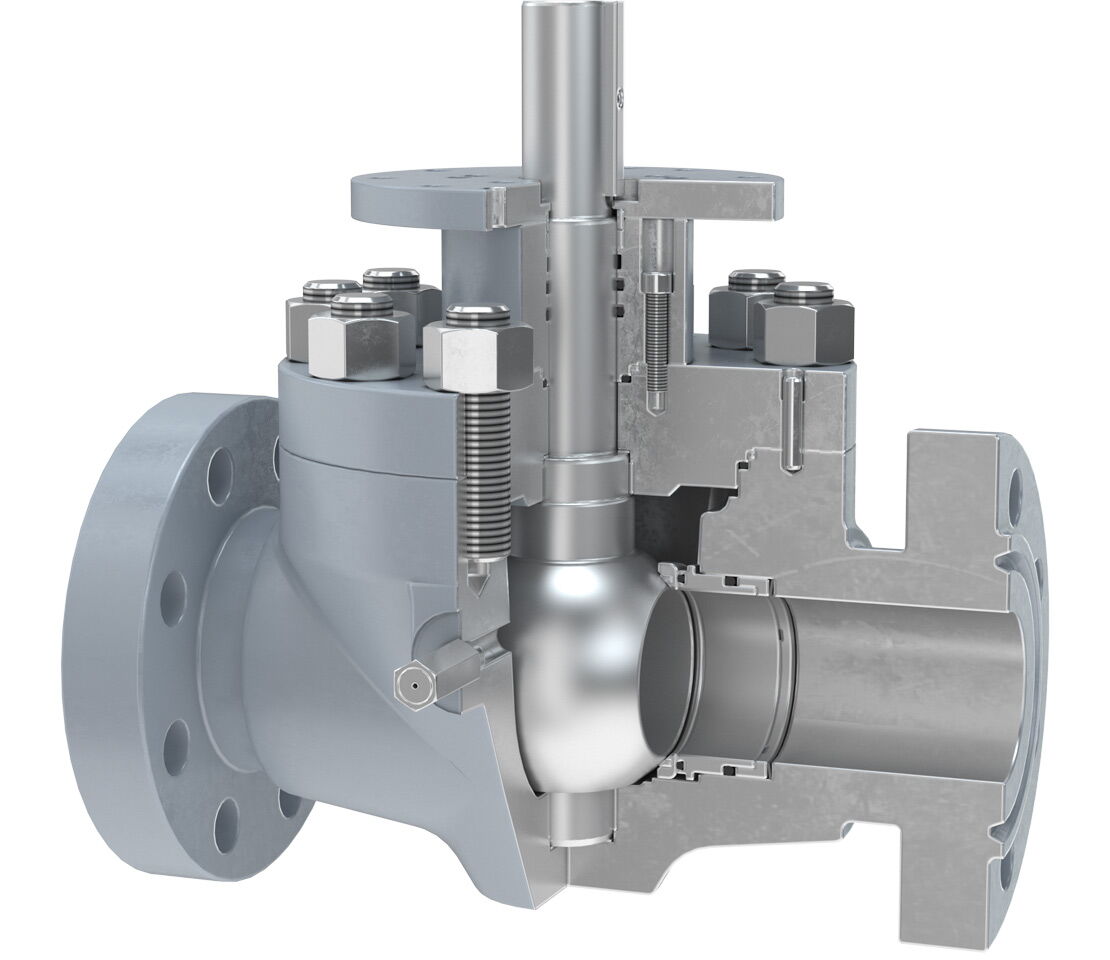

A top entry ball valve is a type of ball valve specifically engineered with an opening at the top of the valve body, allowing internal components like the ball, seat, and stem to be accessed directly from the top. This design eliminates the need to remove the valve from the pipeline during maintenance, making it especially suitable for systems where uninterrupted flow and operational efficiency are essential.

Unlike side entry valves, which require horizontal disassembly, the vertical access feature of top entry ball valves significantly reduces downtime during repairs and inspections. These valves are typically constructed from forged or cast steel and are often used in applications that demand high pressure, high temperature, and high flow capacity.

The core mechanism of a top entry ball valve is straightforward but highly effective. Inside the valve body sits a precision-engineered ball with a bore (hole) through its center. When the ball is rotated using the actuator or manual handle, the bore either aligns with the flow direction to allow fluid passage or turns perpendicular to block the flow.

The unique feature of the top entry design lies in how the internal components are housed. The valve body is typically a single solid piece (or monolithic construction), ensuring enhanced strength and reduced risk of leakage. The top bonnet can be removed without disturbing the connected pipeline, providing direct access to the internal components for easy replacement, cleaning, or inspection.

This makes top entry ball valves particularly useful for "in-line" service, where maintenance needs to be done quickly and with minimal disruption.

There are several types of top entry ball valves available, each suited to specific applications and fluid media. The most common types include:

These valves incorporate a trunnion system, where the ball is supported by upper and lower bearings. This design minimizes torque during operation, improves stability under high pressure, and reduces wear on the seats. Trunnion-mounted valves are ideal for large-diameter pipelines and high-pressure systems, making them a preferred choice for oil and gas transmission lines.

In this design, the ball is not fixed but is held in place by the compression of two elastomeric or metal seats. When pressure is applied, the ball "floats" slightly downstream to create a tight seal against the seat. Floating ball valves are suitable for lower-pressure applications and offer excellent sealing performance for general industrial use.

These valves use metal-to-metal contact between the ball and the seat, allowing them to handle extreme temperatures, corrosive environments, and abrasive media. Metal seated ball valves are often deployed in chemical processing, power plants, and mining operations, where soft-seated valves may degrade or fail prematurely.

One of the standout benefits of top entry ball valves is their ease of maintenance. Since all internal parts can be accessed from the top, technicians can perform inspections, seat replacements, and other repairs without removing the valve from service. This minimizes downtime and operational disruption—an invaluable feature in high-demand process plants.

Top entry ball valves are generally made from forged steel or other high-strength alloys. The one-piece body design enhances pressure tolerance and reduces the potential for leaks at body joints. The robust construction makes them suitable for demanding applications where safety and durability are top priorities.

Whether using soft or metal seats, top entry valves provide tight shut-off capabilities even in high-pressure or high-temperature systems. In critical systems like offshore oil platforms or LNG processing, their ability to maintain a reliable seal is vital for environmental safety and regulatory compliance.

These valves are often employed in pipelines with large bore sizes and elevated pressures. Their trunnion support structure ensures smooth and stable operation, while the top-mounted design allows them to function without interruption—even in confined or remote installation areas.

Due to their rapid and reliable actuation, top entry ball valves are commonly integrated into emergency shut-off systems. Their ability to quickly isolate media flow in the event of a system failure or hazardous leak is crucial in minimizing risk and protecting personnel and equipment.

While both top entry and side entry ball valves serve similar functional purposes, there are important distinctions between the two:

|

Feature |

Top Entry Ball Valve |

Side Entry Ball Valve |

|

Maintenance Access |

Vertical (top-mounted), easy in-line servicing |

Horizontal (side-mounted), requires full removal for service |

|

Body Structure |

Typically one-piece or welded |

Two-piece or three-piece body |

|

Pressure Resistance |

High due to monolithic body |

Slightly less due to multiple joints |

|

Applications |

High-pressure, high-temperature, or large-bore pipelines |

General purpose or medium-pressure systems |

|

Cost |

Generally higher upfront cost |

Lower initial cost but potentially more costly over time due to maintenance complexity |

Top entry ball valves are engineered to handle a wide range of challenging environments. Their design lends itself to industries that require precise flow control and regular maintenance access. Key sectors that rely on top entry ball valves include:

Oil & Gas: Upstream and midstream operations use top entry valves in offshore platforms, pipelines, and refineries due to their high-pressure tolerance and inline serviceability.

Petrochemical Plants: Ideal for handling corrosive fluids, gases, and chemical mixtures under extreme temperatures.

Power Generation: Used in steam systems, cooling water systems, and boiler feed applications.

Water Treatment Facilities: Employed for controlling water flow in filtration, desalination, and distribution systems.

Marine and Offshore: Perfect for subsea systems where valve removal is not practical.

The performance and longevity of a top entry ball valve largely depend on the material and seat combination:

Body Materials: Commonly used materials include forged carbon steel (A105), stainless steel (SS316, CF8M), duplex stainless steel, and Inconel for specialized applications.

Seat Materials: Options include PTFE (Teflon), RPTFE, PEEK, or metal seats depending on the application's pressure, temperature, and fluid characteristics.

Soft seats are often used in standard service conditions due to their excellent sealing, while metal seats are chosen for aggressive media or high-heat applications.

Top entry ball valves represent a high-performance, low-maintenance solution for critical flow control in industrial environments. With their unique vertical access design, robust body construction, and versatile sealing capabilities, these valves offer long-term value, particularly in applications where reliability, safety, and minimal downtime are essential.

From high-pressure pipelines to emergency shut-off systems, the top entry ball valve continues to be a trusted component in the world’s most demanding industries. Whether you are engineering a new plant or upgrading an existing pipeline, considering a top entry ball valve may provide the optimal combination of performance, safety, and serviceability.