As shown in the simulation results from Section 1, the medium pressure beneath the packing fluctuates by approximately 13,700 Pa, which has minimal impact on the packing seal performance. Assuming ideal conditions where the contact pressure on the sealing surface exceeds the medium pressure, no medium leakage occurs, and the medium pressure acts solely on the fluid–solid interface as shown in Figure 2. Based on the initial sealing configuration described in Section 2, an additional load step representing medium pressure is introduced. Under this condition, the effects of medium pressure variation on the radial deformation of the compressed packing and the contact pressure at the sealing surfaces are analyzed. After the initial sealing configuration was established, medium pressures of 45 MPa and 13,700 Pa were applied, respectively. The corresponding maximum radial deformations were 0.099 mm and 0.1102 mm, while the maximum contact pressures reached 53.082 MPa and 53.1876 MPa, respectively. The lower medium pressure results in slightly higher values, leading to greater radial deformation and increased maximum contact pressure on the packing ring. However, the differences are minimal, with the radial deformation increasing by only 2.7% and the maximum contact pressure rising by just 1.9%. These observations indicate that pressure fluctuations have a negligible effect on the packing ring. As a result, the impact of pressure variation on the sealing design is deemed insignificant and is excluded from further analysis. Future seal designs only need to account for the maximum operating pressure while incorporating an appropriate safety margin.

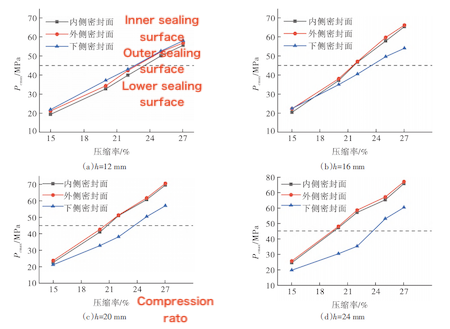

The magnitude of the contact pressure directly indicates the sealing effectiveness of the packing ring. To ensure effective sealing, the maximum contact pressure must be equal to or exceed the medium pressure. When the pressure of the sealed fluid is high, the effective sealing path lengthens, resulting in a more reliable seal. When designing the sealing structure, it is also essential to consider equivalent stress to prevent excessive levels that could cause seal rupture or permanent deformation. Using the control variable method, packing rings of varying heights were analyzed to determine the maximum contact pressure on their sealing surfaces, as shown in Figure 7. As the height-to-width ratio of the packing ring cross-section increases, the maximum contact pressure on the lower sealing surface becomes significantly lower than that on the inner and outer sealing surfaces. Additionally, the contact pressure on the outer sealing surface is slightly higher than on the inner surface. At a constant compression rate, the maximum contact pressure gradually increases with the packing ring height. Conversely, at a fixed packing ring height, the maximum contact pressure increases more rapidly as the compression rate rises.

(a) h = 12 mm (b) h = 16 mm (c) h = 20 mm (d) h = 24 mm

Figure 7. Variation of Maximum Contact Pressure on Sealing Surfaces at Different Packing Ring Heights and Compression Rates

Comparing the maximum contact pressure on the sealing surface to the maximum allowable working pressure of 45 MPa shows that at a 15% compression rate, the contact pressures of packing rings at all heights remain well below 45 MPa. At a 22% compression rate, the peak contact pressure for the 16 mm packing ring reaches 47.1 MPa, leaving a narrow safety margin. The peak pressures for the 20 mm and 24 mm rings are 51.28 MPa and 58.32 MPa, respectively, both significantly exceeding the medium pressure. At a 25% compression rate, the contact pressures for packing rings of all heights significantly exceed the medium pressure. When designing the valve stem packing seal, it is crucial to consider that higher compression rates increase friction, which in turn raises the valve stem’s rotational torque, making operation more difficult and accelerating packing ring wear, ultimately reducing service life. Therefore, pre-tightening to the maximum compression rate should be avoided whenever possible. Considering the manufacturing costs associated with the 316L stainless steel valve body, a smaller packing ring height is preferred. Ultimately, a packing ring height of 20 mm was chosen, with five packing rings installed in combination. The compression rate ranges from 22% to 25%, corresponding to a compression displacement of 4.4 to 5.0 mm. Under these conditions, the sealing performance is reliable and meets operational requirements.

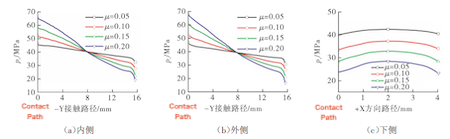

The effect of the friction coefficient on the contact performance of a 20 mm-high packing ring compressed at a 22% rate was analyzed, with the results shown in Figure 8. After compression, the upper end face of the packing ring serves as the starting point of the sealing path along the -Y direction. The contact pressure on both the inner and outer sealing surfaces shows an approximately linear decrease along the sealing path, followed by a sharp drop near the end. In the first half of the sealing path, higher friction coefficients correspond to increased contact pressure. At -Y = 7.8 mm, the contact pressures converge and become equal. However, in the second half of the sealing path, higher friction coefficients lead to lower contact pressures. This trend is consistent with the findings of Zhao et al. The reason is that during clamping, the force is applied from the top, resulting in significant axial compression deformation in the upper portion, while the deformation in the lower half remains relatively small. As shown in Figure 8(c), the contact pressure distribution on the lower sealing surface gradually decreases from the center toward both sides, exhibiting an almost symmetrical pattern. A higher friction coefficient on the lower sealing surface corresponds to a lower contact pressure. The sealing performance is mainly determined by the peak contact pressure along the sealing path. Considering that excessive friction accelerates wear on the sealing ring, a friction coefficient of 0.10 is recommended for optimal sealing performance.

(a) Inside (b) Outside (c) Bottom

Figure 8. Distribution of Contact Pressure on Sealing Surfaces at Different Friction Coefficients

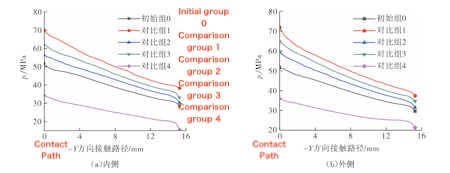

The impact of internal and external clearances between the packing ring, valve stem, and valve body on sealing performance was analyzed. A 20 mm-high packing ring with a 22% compression rate was selected, and four comparison groups were established for the study. The internal and external clearances of the packing ring for each group are detailed in Table 2.

Table 2. Internal and External Fit Clearances of Packing Ring

|

Group No. |

e1 (mm) |

e2 (mm) |

|

Initial Group |

0 |

0.1 |

|

Comparison 1 |

0 |

0 |

|

Comparison 2 |

0 |

0.1 |

|

Comparison 3 |

0.1 |

0 |

|

Comparison 4 |

0.2 |

0.2 |

The calculation results are presented in Figure 9. At the same compression rate, smaller fit clearances lead to better radial extrusion and higher contact pressure. Because the packing ring deforms outward radially faster during compression, a 0.1 mm outer clearance offers better sealing performance than a 0.1 mm inner clearance. However, if the clearance is too small, the equivalent stress may become excessive, potentially leading to rupture of the packing ring. To meet installation requirements, the inner and outer diameter fit clearances are designed as 0.1 mm, based on the JB/T 6617-2016 standard: Technical Conditions for Flexible Graphite Packing Rings for Valves.

(a) Inner Surface (b) Outer Surface

Figure 9. Contact Pressure Distribution on Sealing Surfaces with Different Fit Clearances

Based on the analysis above, the optimized packing seal structure is designed with the following parameters: a total height of 20 mm, a compression rate of 22%, a friction coefficient of 0.1, and a fit clearance of 0.1 mm. The sealing performance of this design is validated through a combination of pressure penetration simulations and experimental testing.

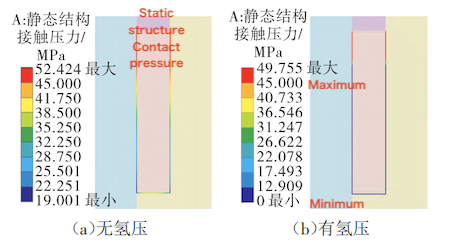

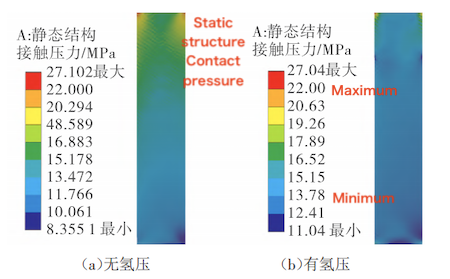

Using the finite element model described in Section 2, a simulation of 45 MPa medium pressure penetration was performed. Figure 10 illustrates the contact pressure distribution on the sealing surface before and after hydrogen pressure is applied. As shown in Figure 10(b), the lower contact pressure region of the sealing surface partially separates after hydrogen pressure is applied, causing a slight reduction in the effective sealing length. The maximum contact pressure decreases to 49.76 MPa, still exceeding the 45 MPa medium pressure requirement and providing a safety margin of approximately 10%. These results confirm that the designed packing structure delivers reliable sealing performance under 45 MPa hydrogen pressure.

(a) Without Hydrogen Pressure (b) With Hydrogen Pressure

Figure 10. Contact Pressure Distribution of Packing Ring Before and After Applying Medium Pressure

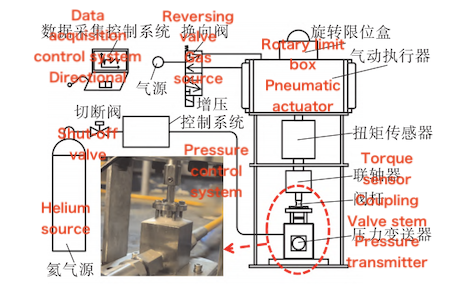

The sealing performance was evaluated using a custom-built high-pressure valve stem sealing test machine. The test setup, shown in Figure 11, includes an ammonia cylinder assembly, a pressurization system, a valve stem drive control system, and a data acquisition system.

The test specimen was a molded, high-purity flexible graphite packing ring with a total height of 20 mm. Each individual ring measured 10.2 mm × 17.8 mm × 4 mm (inner diameter × outer diameter × height) and had a density of 1.6 g/cm³.

Figure 11. Valve Stem Packing Sealing Performance Test Device

The test procedure was as follows:

First, the packing rings were installed into the stuffing box and compressed to the specified compression rate by tightening the bolts. Next, the pressurization system was activated to inject gas and raise the pressure to the target value. The pneumatic actuator then drove the valve stem in rotational motion, accurately simulating the valve’s opening and closing process. Leak detection was performed visually: the presence of bubbles or a drop in monitored pressure indicated leakage, while the absence of bubbles and stable pressure confirmed an intact seal. If leakage was detected, rotation was stopped, pressure was released, and the test was restarted with new packing rings. If no leakage occurred, a life cycle test was conducted under sustained pressure. In accordance with GB/T 13927-2022 "Industrial Valve Pressure Test," two compression rates (20% and 22%) were tested at 1.1 times the maximum working pressure, approximately 50 MPa. The valve stem was rotated through a 90° reciprocating motion, with each cycle lasting 2 seconds and a 5-second interval between rotations.

Test Results:

At a 20% compression rate, significant bubble leakage was observed, causing the pressure to drop before stabilizing around 41.5 MPa. This indicates that the sealing performance is insufficient to maintain 50 MPa pressure. At a 22% compression rate, no leakage was detected using the bubble method, and the test was extended to 1,000 full cycles. Pressure readings collected from the outlet pressure transmitter showed no decay during valve stem rotation, and pressure remained stable throughout a 15-minute hold period, indicating excellent sealing performance. Combined with pressure penetration simulations, these results confirm that the designed packing seal structure delivers reliable and durable sealing performance under a medium pressure of 45 MPa. Figure 12 illustrates the equivalent stress distribution in the packing ring before and after the application of hydrogen pressure. The medium pressure slightly reduces radial deformation, causing a minor decrease in equivalent stress that remains uniformly distributed. Thanks to the mechanical constraints of the valve body and stem, the packing ring does not undergo excessive deformation. The low equivalent stress indicates a minimal risk of permanent deformation or rupture, confirming that the sealing structure is both safe and reliable.

(a) Without Hydrogen Pressure (b) With Hydrogen Pressure

Figure 12. Equivalent Stress Distribution in the Packing Seal Ring

Flow Characteristics of High-Pressure Ball Valves:

The internal flow of high-pressure ball valves is characterized by low velocity, high operating pressure, and a small pressure drop. The maximum flow velocity reaches 32.4 m/s at the outlet of the valve core channel during the closing process, whereas the flow velocity near the fluid–solid interface remains relatively low, ranging from 0 to 4 m/s. Although the interface undergoes a significant pressure fluctuation of approximately 13.7 MPa, its impact on the packing seal performance is minimal. Therefore, excessive flow velocity and pressure differentials can be disregarded in the sealing design. Future structural optimization should prioritize the maximum working pressure and incorporate an appropriate safety margin.

Influence of Structural Parameters on Sealing Performance:

The maximum contact pressure of the packing seal increases with the packing ring’s height, compression rate, and friction coefficient. However, an excessive compression rate can generate high equivalent stress, increasing the risk of permanent deformation or failure of the packing ring. Additionally, increased radial pressure and friction accelerate packing wear, with a higher friction coefficient further contributing to material degradation. Introducing appropriate internal and external clearances between components helps reduce equivalent stress and prevents seal deformation or cracking. Optimizing the packing ring height enhances sealing integrity, contributes to a more compact valve design, and lowers manufacturing costs.

Optimized Parameters for Hydrogen Ball Valve Sealing:

For the high-pressure hydrogen ball valve stem analyzed in this study, the packing seal achieves optimal performance with the following design parameters: total height of 20 mm, inner diameter of 10.2 mm, outer diameter of 17.8 mm, compression rate of 22%, and a friction coefficient of 0.1. These parameters ensure reliable sealing performance under a maximum working pressure of 45 MPa. To accommodate higher pressure requirements, the compression rate and packing ring height can be increased, or V-shaped packing rings can be used to further enhance sealing performance.