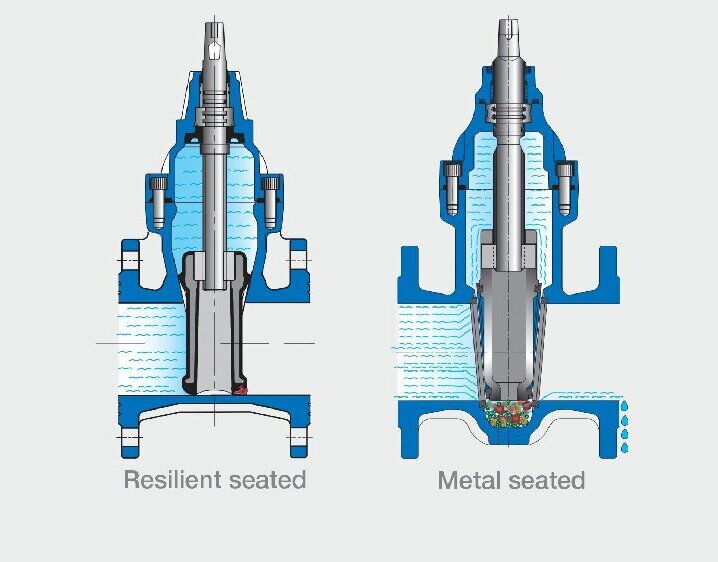

Resilient seated gate valves (RSGVs) have become essential components in various industries due to their superior sealing capabilities, durability, and low maintenance requirements. Unlike traditional metal-seated gate valves, which rely on metal-to-metal contact for sealing, resilient seated gate valves use an elastomeric seat that ensures a tighter, leak-proof closure.

These valves are widely used in water supply, wastewater treatment, fire protection, irrigation, and industrial fluid systems. Their ability to maintain a strong seal even in the presence of minor debris and imperfections makes them a preferred choice for municipal and industrial applications.

In this article, we will explore the working principle, key components, advantages, comparisons with metal-seated gate valves, materials used, manufacturing processes, applications, installation guidelines, maintenance practices, industry standards, and future trends of resilient seated gate valves.

Resilient seated gate valves consist of the following major components:

Valve Body: The main structure that houses all internal components and directs the fluid flow.

Gate (Wedge): A disk that moves up and down to control fluid passage.

Stem: A shaft that connects the gate to the handwheel or actuator.

Resilient Seat: Made of rubber or elastomeric material, ensuring a leak-tight seal when the valve is closed.

Bonnet: The upper part of the valve that encloses the stem and supports the sealing mechanism.

Handwheel/Actuator: The control mechanism used to operate the valve.

Opening the Valve: When the handwheel is turned, the stem raises the gate, allowing the fluid to flow freely. The gate moves completely out of the fluid path, ensuring minimal resistance.

Closing the Valve: Rotating the handwheel in the opposite direction lowers the gate, pressing it against the resilient seat to create a leak-proof seal.

Sealing Mechanism: The soft rubber or elastomeric seat conforms to the gate's shape, filling minor surface imperfections and ensuring a complete shut-off.

This straightforward yet effective design ensures smooth operation and long-term reliability.

Historically, metal-seated gate valves were the industry standard. However, they had significant limitations, leading to the development of resilient seated gate valves.

|

Feature |

Resilient Seated Gate Valve |

Metal Seated Gate Valve |

|

Sealing Mechanism |

Soft, elastomeric seat ensures a tight seal |

Metal-to-metal contact, prone to leakage |

|

Leak Prevention |

Highly effective |

Less effective over time |

|

Debris Handling |

Can handle minor impurities without affecting sealing |

Prone to clogging due to rigid sealing surfaces |

|

Wear and Tear |

Minimal due to elastomeric material |

Prone to corrosion and mechanical wear |

|

Maintenance Requirements |

Low, easy to replace seat |

High, requires frequent repairs |

|

Corrosion Resistance |

Resistant due to rubber coating |

Susceptible to rust and degradation |

|

Application Suitability |

Ideal for water, wastewater, and industrial fluids |

Suitable for high-temperature, high-pressure system |

Metal-seated gate valves require a precisely machined groove in the bottom of the valve to ensure a tight seal. Over time, sand, pebbles, and impurities can accumulate in this groove, preventing a complete shut-off and leading to operational inefficiencies. The rigid sealing mechanism also makes them more vulnerable to wear and tear, requiring frequent maintenance.

In contrast, resilient seated gate valves eliminate this issue by using a flexible seat that adapts to minor imperfections, ensuring a long-lasting, leak-proof performance.

The valve body must be strong and corrosion-resistant. Common materials include:

Ductile Iron: Most common due to its strength and cost-effectiveness.

Cast Iron: Used in older systems but less common today.

Stainless Steel: Preferred for highly corrosive environments.

Bronze or Aluminum Bronze: Used in marine and seawater applications.

The choice of seat material impacts the valve’s performance:

EPDM (Ethylene Propylene Diene Monomer): Excellent for potable water applications.

NBR (Nitrile Butadiene Rubber): Best for oil, fuel, and gas applications.

Neoprene: Suitable for industrial applications with exposure to chemicals.

The selection of materials depends on the specific application, ensuring optimal performance and longevity.

The valve body and bonnet are typically cast from ductile iron or stainless steel. Once cast, they undergo precise machining to ensure proper fitment of components.

The gate is fitted with a resilient seat, and all components are assembled, including the stem, handwheel, and sealing rings.

Most modern valves are coated with fusion-bonded epoxy to prevent rust and ensure durability.

Each valve undergoes:

Hydrostatic pressure testing to check for leaks.

Functional testing to ensure smooth operation.

These quality control steps ensure that the valve meets industry standards before reaching the market.

To ensure proper operation:

Positioning: Install the valve in the correct flow direction, as indicated on the body.

Piping Considerations: Ensure the pipe system is free from debris before installation.

Torque Requirements: Do not overtighten bolts, as this may damage the sealing components.

Flange Alignment: Misalignment can cause leaks and operational issues.

Regular Inspections: Check for signs of wear or leaks.

Lubrication: Ensure the stem and moving parts are properly lubricated.

Seat Replacement: If sealing performance declines, replace the elastomeric seat.

Due to their simple design and robust construction, resilient seated gate valves require minimal maintenance compared to traditional metal-seated alternatives.

Resilient seated gate valves are commonly used in:

Water Distribution Systems: Municipal water supply and distribution networks.

Wastewater Treatment Plants: Managing flow in sewage and wastewater facilities.

Fire Protection Systems: Installed in fire hydrants and sprinkler systems.

Industrial Pipelines: Used in chemical, oil, and gas industries.

Irrigation Networks: Controlling water flow in agricultural irrigation systems.

Their versatility and efficiency make them an indispensable component in modern fluid control systems.

To ensure quality, resilient seated gate valves must comply with several international standards, including:

AWWA C509/C515: Standards for water system gate valves.

ISO 7259: International standard for resilient seated valves.

EN 1074-2: European standard for potable water gate valves.

BS 5163: British standard for resilient seated gate valves.

Compliance with these standards ensures reliability, safety, and long service life.

The valve industry continues to evolve, with emerging trends including:

Smart Valves: Integration of sensors for real-time monitoring.

Improved Elastomers: Advanced materials for better sealing performance.

Sustainability: Eco-friendly manufacturing and recyclable materials.

With ongoing technological advancements, resilient seated gate valves will continue to be a crucial component in industrial and municipal infrastructure.

Resilient seated gate valves offer a superior alternative to traditional metal-seated valves, providing better sealing, lower maintenance, and longer service life. Their versatile applications, cost-effectiveness, and compliance with industry standards make them an essential choice for water distribution, wastewater management, industrial pipelines, and fire protection systems.

As technology advances, these valves will continue to play a vital role in modern infrastructure, ensuring efficient and reliable fluid control for years to come.