In modern industrial automation and process control, precise regulation of fluid flow is essential for efficiency, safety, and performance. Pneumatic On/Off Globe Control Valves are integral components in various industries, providing reliable shut-off and precise control of liquids, gases, and vapors. These valves are specifically designed to handle demanding applications where tight sealing, rapid response, and operational reliability are crucial.

By integrating advanced design features with pneumatic actuation, these valves ensure seamless operation in sectors such as oil and gas, power generation, chemical processing, and water treatment. This article delves into the key features, benefits, and applications of Pneumatic On/Off Globe Control Valves, illustrating their critical role in optimizing industrial processes.

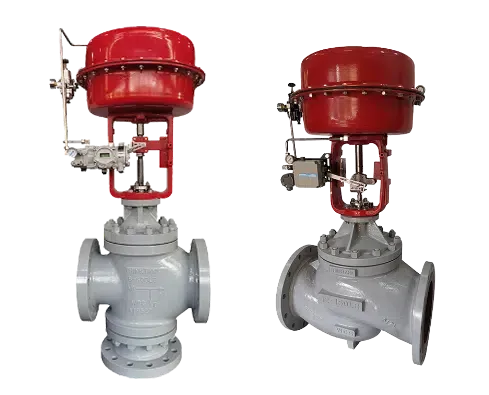

A Pneumatic On/Off Globe Control Valve is a type of linear motion valve that regulates or completely shuts off the flow of a process fluid using a pneumatically operated actuator. This actuator utilizes compressed air to swiftly open or close the valve, offering high-speed response and consistent performance.

Unlike traditional manual valves, which require human intervention, pneumatic valves enable automated and remote operation, making them ideal for large-scale industrial systems that demand precise and reliable flow management.

These valves feature a modular construction, allowing customization with various components such as:

Handwheels for manual operation backup

Metal bellows seals for enhanced leak prevention

Thermal extensions for high-temperature applications

Solenoid valves, limit switches, and positioners for improved automation and control integration

By incorporating these accessories, industries can optimize the valve’s performance based on specific process requirements.

Pneumatic On/Off Globe Control Valves offer several advantages that make them a preferred choice for industrial applications:

The streamlined body and compact structure allow easy installation, even in space-constrained environments such as offshore platforms, industrial plants, and processing facilities.

The modular design supports a wide range of configurations, enabling industries to tailor the valve with additional components to meet specific operational needs. This enhances compatibility with diverse process conditions.

The inclusion of a PTFE (Polytetrafluoroethylene) insert in the plug ensures a Class VI bubble-tight shut-off, preventing leakage and ensuring total process fluid containment. This is particularly valuable in high-pressure and high-temperature environments.

Constructed from robust materials, these valves can withstand extreme temperatures, aggressive chemicals, and corrosive environments. The bonnet and body are manufactured from the same material, preventing differential expansion and increasing the valve’s lifespan.

With rapid response times and tight shut-off capabilities, these valves minimize fluid loss, optimize efficiency, and enhance overall safety in hazardous industrial conditions.

The modular and streamlined design simplifies inspection, servicing, and part replacements, thereby reducing downtime and long-term maintenance costs.

Pneumatic On/Off Globe Control Valves integrate seamlessly with advanced process control systems, including PLC (Programmable Logic Controllers) and SCADA (Supervisory Control and Data Acquisition) systems, allowing precise flow control with minimal human intervention.

Pneumatic On/Off Globe Control Valves are used across numerous industries due to their ability to deliver accurate flow control, safety, and reliability in demanding operational conditions.

These valves are extensively used in oil refineries, gas processing plants, and pipeline systems for controlling the flow of crude oil, natural gas, and refined products. Their ability to provide leak-proof sealing ensures safe operations in hazardous environments.

In the chemical industry, these valves regulate the flow of highly corrosive, toxic, and volatile substances. Their robust material construction ensures compatibility with aggressive chemicals, reducing the risk of contamination and equipment failure.

In thermal and nuclear power plants, Pneumatic On/Off Globe Control Valves are crucial for managing steam, cooling water, and boiler feed water. Their high-temperature and high-pressure tolerance make them ideal for critical power plant applications.

Municipal and industrial water treatment plants use these valves to control the flow of water, chemicals, and sludge. Their corrosion resistance and zero-leakage sealing ensure smooth and efficient wastewater management.

Industries that require strict hygiene standards, such as pharmaceutical and food production, benefit from these valves due to their sanitary design, smooth operation, and contamination-free sealing mechanisms. They ensure precise dosing and flow control of liquids and gases.

Pneumatic On/Off Globe Control Valves are used in heating, ventilation, and air conditioning (HVAC) systems to regulate the flow of steam, water, and air. Their precise control ensures optimal temperature and pressure management in large-scale buildings, hospitals, and industrial complexes.

With increasing automation in industrial processes, the demand for reliable, efficient, and durable control valves is growing. Pneumatic On/Off Globe Control Valves address these needs by offering:

Seamless automation and integration into existing process control systems

High-speed operation and fast response times

Long service life and minimal maintenance requirements

Compliance with international safety and performance standards

Pneumatic On/Off Globe Control Valves are indispensable in modern industrial settings, ensuring precise flow regulation, tight shut-off, and high reliability. Their compact design, robust construction, and automation-friendly features make them an optimal choice for industries requiring efficient and safe fluid management.

By integrating these valves into their systems, industries can achieve enhanced process efficiency, reduced downtime, and greater operational safety. Whether used in power plants, refineries, chemical plants, or HVAC systems, these valves play a pivotal role in industrial automation and process optimization.

As industries continue evolving and demanding advanced flow control solutions, Pneumatic On/Off Globe Control Valves will remain at the forefront of efficiency, safety, and technological innovation in industrial process control.

This version expands on the original article with more technical details, industry-specific insights, and additional benefits, making it more engaging and informative for readers. Let me know if you’d like further refinements!