As industries continue to demand heightened reliability, precision flow control, and long service life from their fluid handling systems, the role of the angle globe valve remains essential. This valve variant—designed with a 90-degree angle between the inlet and outlet—offers benefits such as efficient throttling, reduced number of pipeline fittings, and space-saving installation. It is frequently deployed in steam systems, cooling circuits, high-pressure lines, and corrosive media where consistent regulation is essential.

While angle globe valves are known for durability and accurate flow regulation capabilities, consistent maintenance is necessary to keep them operating efficiently and avoid sudden system failures. In this feature, we outline a comprehensive maintenance guide, detailing the structure and working principle of the valve, followed by systematic steps and best practices for long-term care.

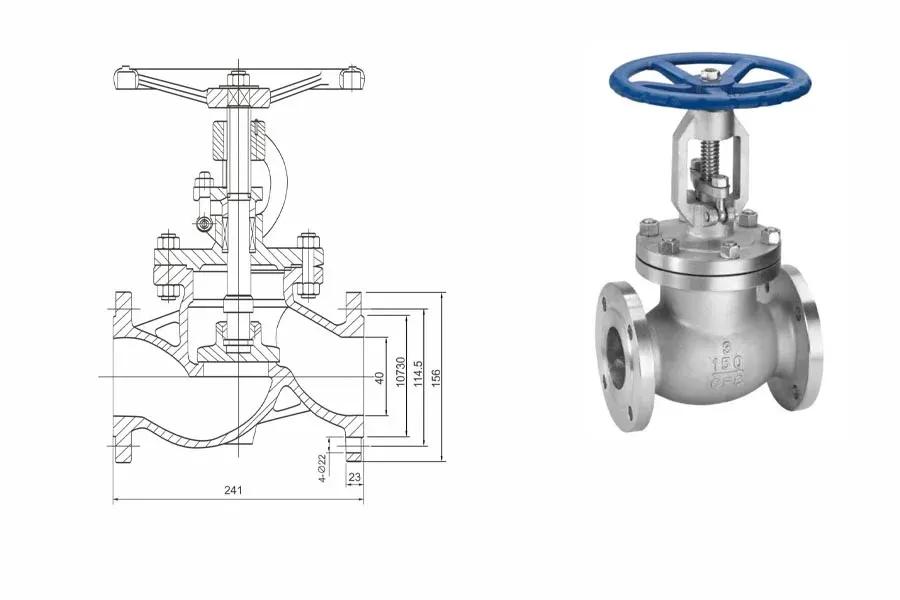

An angle globe valve shares many functional similarities with the standard globe valve but features a specialized body structure. Traditional globe valves have a straight-through body design, whereas the angle globe valve diverts flow at a 90-degree angle. This layout helps eliminate the need for a separate elbow fitting, offering smoother redirection of flow with lower installation costs and less turbulence when correctly sized.

However, the throttling action—which relies on a disk moving down toward a seat—does create a localized pressure drop. If installed incorrectly or in the wrong type of service, this turbulence can lead to erosion or noise. Therefore, understanding how and where to use an angle globe valve is just as important as maintaining it.

The functionality of an angle globe valve is centered on regulating flow with precision. Below are the core components and how they work together:

The valve body is cast or forged in a design where the inlet and outlet form a 90-degree turn. This makes it perfect for tight installations or when pipeline layouts require a directional shift without adding a separate elbow joint. The internal flow path is engineered to minimize pressure loss as much as possible.

The disc (or plug) is the active component that moves to open, throttle, or close the flow. When the disc lowers onto the seat, it restricts or halts the passage of fluid. The design of the seating area helps achieve a gradual throttling effect, making these valves particularly suitable for modulating service.

The stem connects the disc to the actuator or handwheel. The actuator can be manual, electric, pneumatic, or hydraulic, depending on the system's level of automation. The up-and-down movement of the stem translates directly into changes in flow.

To prevent leakage when in the closed position, sealing elements such as PTFE, graphite rings, or elastomers are used. The effectiveness and longevity of these seals often depend on operating temperature, pressure, and chemical compatibility.

Angle globe valves are designed to balance control and efficiency. Their layout allows a relatively streamlined flow path, reducing turbulence levels compared to most standard globe valves when installed correctly and sized properly for the system.

Maintaining angle globe valves is not just about ensuring isolation or flow control. It’s about preserving the safety, stability, and operational lifespan of entire systems. Below, we provide a detailed maintenance roadmap for industrial settings.

Regular inspections form the backbone of preventive maintenance. Whether your facility runs weekly, monthly, or quarterly checks, consistency is essential.

Check for leaks around the gland packing area, flange joints, and body.

Look for corrosion or signs of chemical attack on the external surfaces.

Inspect hand wheels, actuators, and positioners to ensure they are functioning smoothly and without excessive vibration.

Even if it seems repetitive, it's safer to inspect more often than to suffer a costly shutdown due to neglect.

Valves that remain fixed in one position for extended periods may become stuck or experience seat bonding.

Operate the valve through a full open-close cycle periodically.

This prevents the disc from seizing against the seat and ensures that the spindle and internal surfaces remain mobile.

For automated systems, include cycle testing in your maintenance schedule.

Fasteners around the valve, such as gland flange bolts, bonnet bolts, and actuator mounting screws, should be checked periodically.

Avoid overtightening, as excessive torque can warp the body or stem packing.

Avoid undertightening, which can cause leaks or misalignment.

Use a calibrated torque wrench where possible and follow manufacturer specifications.

Angle globe valves are often used in high-pressure systems. Maintaining stable pressure is essential for both valve performance and safety.

Install pressure gauges or sensors upstream and downstream of the valve.

If pressure variation is detected, investigate whether it is due to valve wear, particle blockage, or upstream equipment issues.

In larger systems, integrate digital sensors connected to a centralized control system for live feedback and alerts.

Proper lubrication extends the lifespan of the spindle, yoke sleeve, actuator linkages, and handwheel mechanisms.

Ensure that grease fittings (nipples) on the crossbar or yoke receive periodic injections of suitable grease.

For manual valves, grease gears and stem threads.

In automated systems, ensure the actuator itself (if mechanical) is lubricated according to supplier guidelines.

The gland packing prevents fluid from leaking around the stem. Over time, packing can wear, harden, or degrade.

Inspect the gland area for leaks or drips.

If leaks persist even after tightening the packing flange, it may be time to replace the packing rings.

Use suitable materials (graphite, PTFE, etc.) based on temperature and chemical service.

Sediment, mineral scaling, or debris buildup inside the valve body can interfere with throttling accuracy and create pressure losses.

During a scheduled shutdown, dismantle the valve and clean the disc, seat, and body cavity with appropriate tools and solvents.

If handling corrosive or hazardous fluids, ensure proper safety measures and containment procedures are followed.

For automated angle globe valves with pneumatic or electric actuators:

Check electrical wiring or air lines for damage or leaks.

Test the responsiveness of the actuator to control signals.

Keep actuator housings clean and protected from moisture or dust buildup.

For pneumatic systems, ensure filters and regulators are free from oil or water contamination.

If your angle globe valve is part of a control loop, regular calibration is crucial to sustain precise flow control.

Calibrate positioners and feedback sensors.

Verify that actual valve position matches control system readouts.

If there is a mismatch, adjust the positioner or recalibrate the actuator.

Every inspection, adjustment, and repair should be documented.

Keep thorough maintenance records including date, findings, corrective actions, and parts replaced.

Use digital CMMS (Computerized Maintenance Management System) if possible to track valve performance and identify patterns that may require preventive action.

A properly maintained angle globe valve can serve reliably for many years, reducing overhead costs and protecting personnel and equipment. Long-term benefits include:

Extended Valve Lifespan: Reduces need for replacement.

Improved System Reliability: Lowers risk of downtime.

Enhanced Safety Compliance: Minimizes accident or leak risk.

Optimized Flow Control: Maintains accuracy for throttling operations.

Lower Operating Costs: Prevents major failures that require costly repairs.

Angle globe valves offer a strong combination of flow control precision, design efficiency, and durability. However, without a strategic approach to maintenance—which includes routine inspections, cycling, lubrication, seal checks, actuator calibration, and pressure monitoring—these advantages can quickly be compromised.

By adopting a structured maintenance plan, industrial operators not only extend the working life of each valve but also ensure stable process conditions across the entire system. A proactive mindset, supported by proper documentation and trained personnel, allows angle globe valves to perform safely and effectively under demanding service conditions for many years.