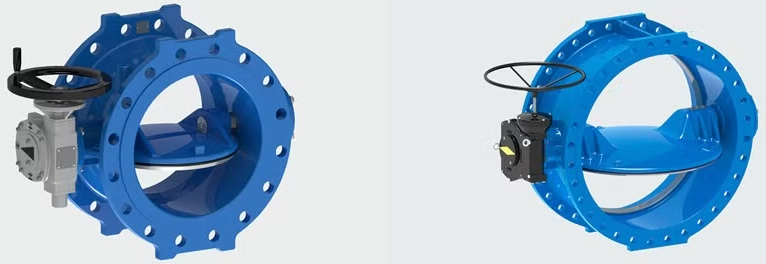

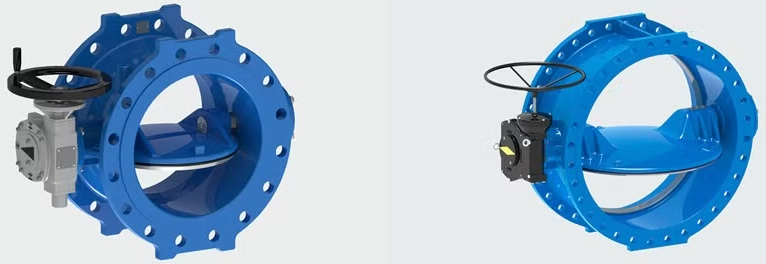

In industrial and municipal water systems, efficient valve design is paramount for reliability, cost-effectiveness, and long service life. Among the advancements in valve technology, double eccentric butterfly valves have become essential due to their unique construction, which not only enhances performance but also reduces maintenance needs. With their ability to minimize wear on critical components, these valves are a preferred choice in various water supply applications. Here’s a look at the unique features of double eccentric

butterfly valves and why they are increasingly favored over traditional gate valves.

The double eccentric design—also known as a double-offset butterfly valve—offers several advantages over other types of valves. The primary distinction lies in the placement of the disc in relation to the centerline of the seat and shaft, creating two offsets that prevent the disc from rubbing directly against the seat during operation. This innovation results in several critical benefits:

The double eccentric configuration reduces wear on the disc seal, which is typically a vulnerable point in valve design. With traditional valves, the disc remains in constant contact with the seat, leading to friction and eventual wear. In contrast, the double eccentric butterfly valve’s design ensures that as soon as the disc opens even slightly, tension on the disc is released. This reduced friction leads to a longer-lasting disc seal, allowing for a more reliable, low-maintenance solution.

Due to the design’s reduced compression on the sealing element, double eccentric butterfly valves require less torque to operate. This decrease in torque results in easier operation, which can translate to reduced power consumption in automated systems and easier manual operation when needed. For large-scale installations, this advantage leads to significant operational efficiencies and potential cost savings.

Double eccentric butterfly valves offer flexibility in terms of seating materials and configurations, allowing users to choose an option best suited for their specific application. Typically, there are three primary seat designs:

This design features a seat machined directly into the ductile iron body, which is then epoxy coated for added durability. The integral seat is particularly valued in applications where ease of maintenance and longevity are priorities. Epoxy coating provides additional corrosion resistance, making it an excellent choice for long-term installations in harsh environments.

This variant features a replaceable stainless steel seat ring that is sealed with an O-ring to prevent leakage beneath the seat ring. The replaceable seat design is beneficial for applications where wear is more likely or maintenance schedules are tightly regulated. Should the seat become worn, it can be replaced without the need to remove the entire valve body from the pipeline, saving both time and costs.

A welded stainless steel seat is machined and polished for a smooth surface, reducing the potential for friction even further. This design is ideal for systems requiring extremely low friction and high durability, offering both longevity and reliability.

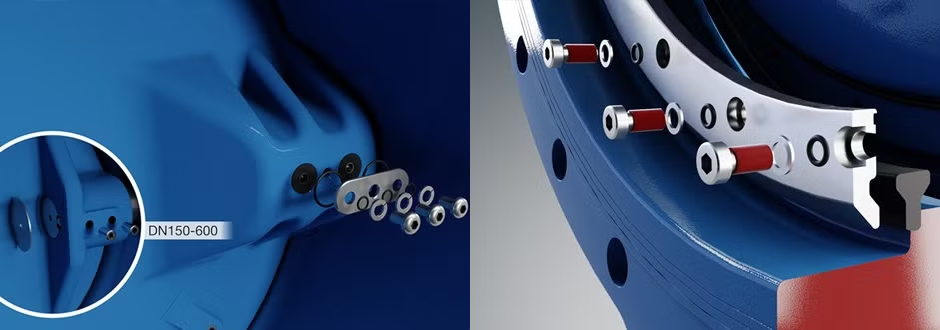

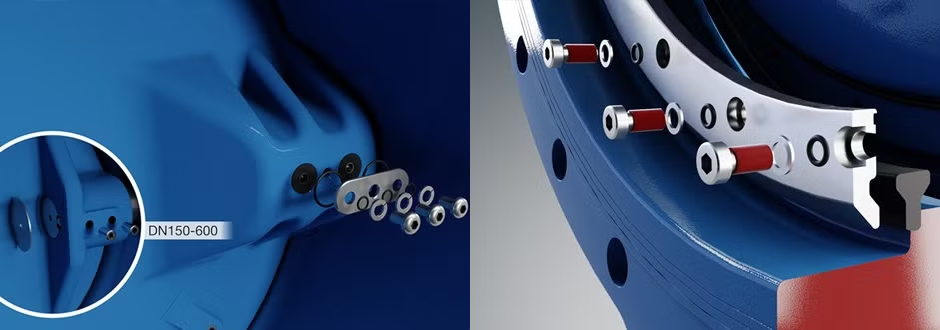

A key consideration in valve design is ensuring that the disc and shaft are securely connected, particularly under high flow rates where vibration and flow-induced forces can cause instability. In double eccentric butterfly valves, the disc and shaft connection is designed for maximum stability and safety.

For smaller and medium-sized valves, a key and keyway connection method is used, with the key secured by two set screws to prevent fluttering. This minimizes play in the connection and ensures a robust attachment. In larger valves, additional stainless steel drive dowels are employed to further reinforce the connection. Together, these features prevent disc fluttering, reducing wear and maintaining alignment, which is crucial for valves subjected to varying pressures and flow rates.

Double eccentric butterfly valves have traditionally been used in water supply systems, particularly for underground installations. Their suitability in these environments arises from several factors:

Compared to gate valves, butterfly valves generally offer a more economical solution, especially in larger dimensions. The simplified construction of a butterfly valve reduces material and manufacturing costs, making it a favorable option for budget-conscious projects.

When installing valves below ground, bury depth is an important factor. Double eccentric butterfly valves require a lower bury depth than gate valves, which means less excavation is needed during installation. This aspect is particularly advantageous in urban areas where underground space can be limited, and reducing excavation can result in significant savings in both time and resources.

Although primarily utilized for below-ground water supply systems, double eccentric butterfly valves can also be installed above ground, where their compact design and low maintenance requirements provide additional benefits.

In addition to their economic benefits, double eccentric butterfly valves offer operational advantages that make them a preferred choice in modern water supply infrastructure. Their efficient design aligns with the industry’s push towards cost-effective, sustainable, and low-maintenance solutions. As municipalities and industrial facilities look for ways to optimize their water supply systems, the choice of valve plays an essential role in achieving reliability and long service life.

Moreover, advancements in materials, such as epoxy coatings and stainless steel seating, allow double eccentric butterfly valves to withstand harsh environments and high pressures. This resilience contributes to reduced leakage and the assurance that water supply remains reliable—a crucial aspect in today’s world where water conservation is more important than ever.

Double eccentric butterfly valves represent a significant step forward in valve technology, offering enhanced durability, reduced maintenance, and cost savings in water supply applications. Their thoughtful design minimizes wear on critical components, ensures secure disc and shaft connections, and provides flexible seating options to meet a range of operational needs.

For industries and municipalities looking to enhance the efficiency and reliability of their water systems, these valves offer a powerful solution. As demand for high-performance, cost-effective, and durable water infrastructure grows, double eccentric butterfly valves are well-positioned to play a leading role in shaping the future of water supply networks.