Cryogenic systems occupy a unique and demanding space within modern industry. From liquefied natural gas (LNG) and liquid oxygen (LOX) to high-purity nitrogen, hydrogen, and helium applications, these systems operate at temperatures far below those encountered in typical industrial processes. At such low temperatures—often dipping below –150°C—materials behave differently, transmission systems become more sensitive to environmental fluctuations, and components must be engineered to withstand intense thermal stress.

Among the many specialized components used in cryogenic environments, cryogenic check valves play an indispensable role. These valves serve as autonomous safety devices that ensure media flows in one direction only, preventing hazardous reverse flow that could compromise process stability or cause equipment failure. When primary control valves malfunction or when pressure conditions unexpectedly shift, the check valve functions as a guardian, protecting vulnerable system components from damage.

To maintain the high performance expected in these critical systems, proper maintenance of cryogenic check valves is essential. This article explores what cryogenic check valves are, how they function, the materials used in their construction, key maintenance practices, and evolving trends within the cryogenic equipment industry.

Cryogenic check valves are one-way valves engineered to manage the flow of cryogenic liquids or gases in extreme-low-temperature environments. Their primary purpose is simple yet vital: permit forward flow and prevent reverse flow, thereby safeguarding both equipment and personnel.

These valves are widely used across multiple industries, including:

Liquefied Natural Gas (LNG) production, storage, and transportation

Air separation units (ASUs) producing oxygen, nitrogen, and argon

Hydrogen and helium liquefaction systems

Superconducting research facilities

Cryogenic medical systems, such as those involving liquid nitrogen

Space propulsion systems, where cryogenic fuels like LOX and LH2 are common

Because cryogenic media can rapidly vaporize when exposed to higher temperatures, maintaining precise control of flow direction is crucial for preventing system instability.

Cryogenic check valves typically include:

Valve Body

Constructed from metals capable of tolerating extreme cold, such as stainless steel, duplex stainless steel, or nickel-based alloys.

Disc or Poppet

Moves freely to allow forward flow and immediately closes to block backflow. Must retain toughness at subzero temperatures.

Seat

Provides the sealing surface for the disc. Designed to remain leak-tight despite thermal contraction.

Spring (optional)

Used in spring-loaded designs to ensure quick closure when forward flow ceases.

Extended Bonnet (common in cryogenic designs)

Keeps packing and sealing materials outside the ultra-cold service zone to prevent freezing.

Together, these elements allow the valve to perform reliably even under severe thermal stress and rapid pressure fluctuations.

The importance of cryogenic check valves stems from multiple operational and safety considerations:

Reverse flow in cryogenic pipelines can cause contamination, pressure swings, or catastrophic mechanical failure. Check valves act as an automatic safeguard.

Many cryogenic liquids expand rapidly when heated. Preventing backflow reduces the risk of pressure buildup, leaks, or violent phase changes.

In systems like air separation plants or LNG vaporization lines, maintaining unidirectional flow is essential for accurate process control.

If the primary control valve fails or remains partially open due to ice formation, the check valve provides backup protection.

Stable flow patterns reduce thermal losses and improve overall system efficiency.

To ensure long-term reliability, cryogenic check valves require structured, qualified maintenance practices. Properly maintained valves last longer, experience fewer failures, and help maintain the integrity of cryogenic installations.

Below are the most important maintenance measures and best practices.

Routine inspection is the backbone of cryogenic valve maintenance. Because cryogenic environments can introduce ice formation, frosting, and mechanical stress, regular checks are vital.

Signs of cryogenic leakage, indicated by frost lines or ice buildup

Seat wear, leading to reduced sealing capability

Spring fatigue in spring-loaded models

Corrosion or micro-cracking due to thermal stress

Use only approved, cryogenic-compatible cleaning agents. Remove dust, metal particles, and any frozen contaminants. Pay particular attention to sealing surfaces, as even small debris can compromise performance in high-purity cryogenic media.

A clean valve is essential to avoid binding, sticking, or prolonged seating times, all of which can lead to operational hazards.

Lubrication in cryogenic systems is challenging: many lubricants become too viscous or brittle at extremely low temperatures. Therefore, only specialty lubricants approved by the valve manufacturer should be used.

Apply sparingly to avoid attracting debris.

Focus on areas with dynamic movement, such as stems and hinge points.

Use products formulated specifically for liquid nitrogen, LNG, and LOX environments.

Seals, gaskets, and packing materials should also be inspected frequently. Cryogenic cycling causes materials to expand and contract repeatedly, eventually leading to wear, shrinkage, or cracking.

Replace seals as soon as early signs of degradation appear. A compromised seal in a cryogenic system can lead to dangerous leaks or oxygen enrichment hazards.

Cryogenic valves face steep temperature gradients. Sudden temperature changes can cause materials to contract unevenly, resulting in cracking or embrittlement.

Always bring valves to operating temperature gradually.

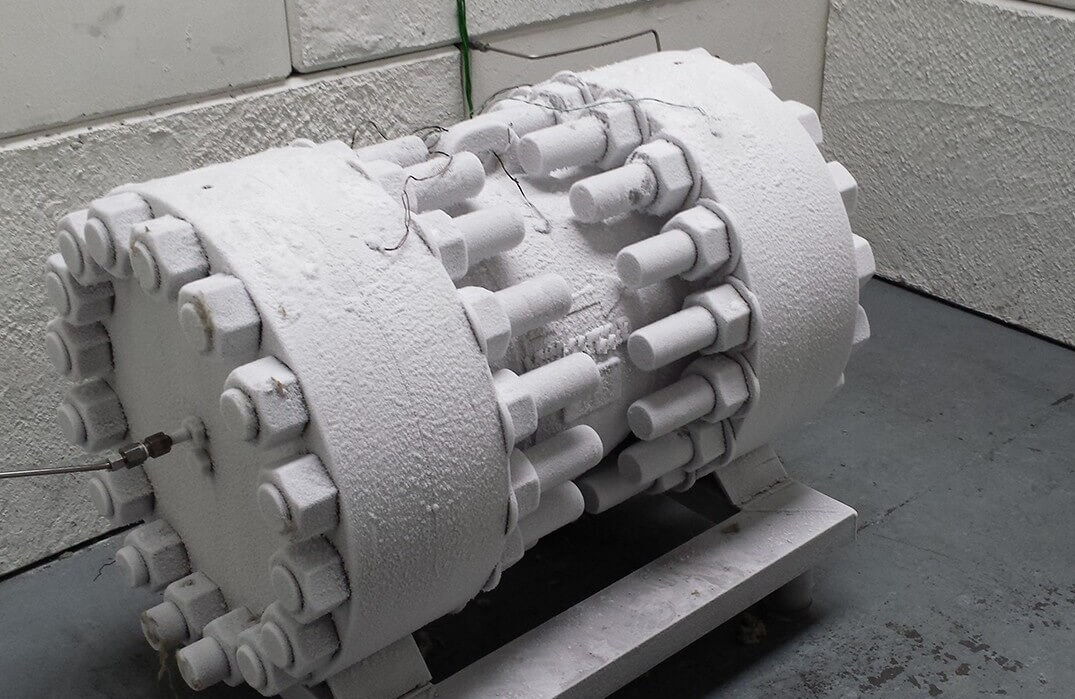

Use thermal insulation blankets or wraps to slow heat transfer.

Avoid introducing cryogenic media into warm lines too quickly.

Implement temperature monitoring systems during shutdown and startup.

Gradual transitions preserve valve integrity and greatly extend service life.

In systems where check valves are paired with actuated valves or integrated into automated control networks, actuator health is equally important.

Inspect electrical connections for wear, corrosion, or ice intrusion.

Evaluate pneumatic or hydraulic supply sources for leakage or pressure instability.

Check actuator calibration to ensure precise valve movement.

Lubricate moving parts according to manufacturer guidelines.

Faulty actuators can lead to misalignment or delayed closure of check valves, increasing operational risk.

Proper maintenance is only possible when personnel are adequately trained and when comprehensive documentation is maintained.

Cryogenic safety procedures

Hazard recognition

Valve operation principles

Emergency response protocols

Material behavior at low temperatures

Inspection logs

Component replacement history

Calibration records

Incident reports

Compliance documents

Documentation not only ensures regulatory compliance but also allows engineers to identify recurring trends or system weaknesses.

The performance of a cryogenic valve is strongly influenced by the materials used in its construction. Standard materials often become brittle at low temperatures, making them unsuitable for cryogenic service.

These are the most widely used materials for cryogenic valves due to:

Excellent corrosion resistance

Good low-temperature toughness

Reduced risk of carbide precipitation

Availability and cost-effectiveness

316L, containing molybdenum, provides superior corrosion resistance in chloride-rich or marine environments.

Nickel alloys are preferred for extremely demanding cryogenic applications, including:

Hydrogen service

Helium systems

LOX applications in aerospace

High-pressure cryogenic lines

Benefits include:

Exceptional strength at low temperatures

Superior resistance to thermal fatigue

Minimal embrittlement

Used in lightweight cryogenic systems, particularly in aerospace or mobile LNG equipment. Aluminum offers excellent conductivity but lower overall strength than stainless steel.

Suitable for moderate-pressure cryogenic applications where thermal conductivity and corrosion resistance are priorities.

Even the best-designed cryogenic check valve will fail prematurely if installed incorrectly.

Always install in the correct flow direction, clearly marked on the valve body.

Ensure pipelines are clean and free of debris before installation.

Avoid excessive pipeline stress by aligning flanges properly.

Use extended bonnets where necessary to keep stem packing above freezing temperatures.

Pressure-test systems prior to introducing cryogenic liquids.

Proper installation minimizes mechanical stress and enhances operational reliability.

Understanding typical failure modes helps operators prevent downtime and safety incidents.

Caused by debris, ice, or seat wear. Preventive cleaning and timely seat replacement reduce risk.

Usually caused by ice buildup or misalignment. Proper lubrication and inspection prevent this.

Occurs when valves are exposed to sudden temperature shifts. Slow equilibration minimizes risk.

In spring-loaded valves, repeated cycling can weaken the spring. Scheduled replacement is essential.

Improper material selection can cause fractures. Always verify materials meet cryogenic specifications.

As cryogenic technologies advance, so do the expectations placed on valves and system components.

The global shift toward cleaner energy is increasing demand for:

LNG transportation

Liquid hydrogen fueling systems

Cryogenic storage infrastructure

This growth drives innovation in valve materials, automation, and reliability.

Cryogenic valve manufacturers are exploring 3D-printed components to achieve:

Reduced weight

Complex geometries

Superior flow characteristics

Sensors integrated into cryogenic valves enable:

Real-time leak detection

Predictive maintenance

Remote monitoring

This reduces downtime and enhances system safety.

Industry bodies are updating cryogenic equipment standards, affecting:

Material qualification

Testing procedures

Valve certification

Environmental safeguards

Compliance helps facilities maintain safe, modern cryogenic systems.

Cryogenic check valves are fundamental components in systems operating at extreme low temperatures. They provide essential protection against reverse flow, contribute to operational safety, and help maintain stable, efficient processes across industries ranging from LNG and gas separation to medical and aerospace applications.

Maintaining these valves requires a disciplined approach—including routine inspection, cleaning, lubrication, thermal shock prevention, accurate actuator maintenance, and thorough documentation. Equally important is selecting the right materials and ensuring proper installation. As cryogenic technologies continue evolving, innovations in smart monitoring, materials science, and valve design will shape the future of cryogenic systems.

A well-maintained cryogenic check valve not only enhances system performance but also protects life, property, and the environment. Through proactive care and adherence to best practices, operators can ensure these critical devices continue delivering reliable service even in the harshest, coldest conditions.

Previous: Do Butterfly Valves Need Gaskets?