Forged steel globe valves are essential components in various industrial applications, known for their durability, reliability, and ability to handle high-pressure and high-temperature environments. These valves are widely used in industries such as oil and gas, power generation, petrochemicals, and water treatment, where precise flow control and shut-off are critical. With designs such as Y-pattern, T-pattern, and angle pattern, forged steel globe valves offer versatility and efficiency in managing fluid flow. This article delves into the design, selection principles, and applications of forged steel globe valves, with a particular focus on Y-pattern globe valves.

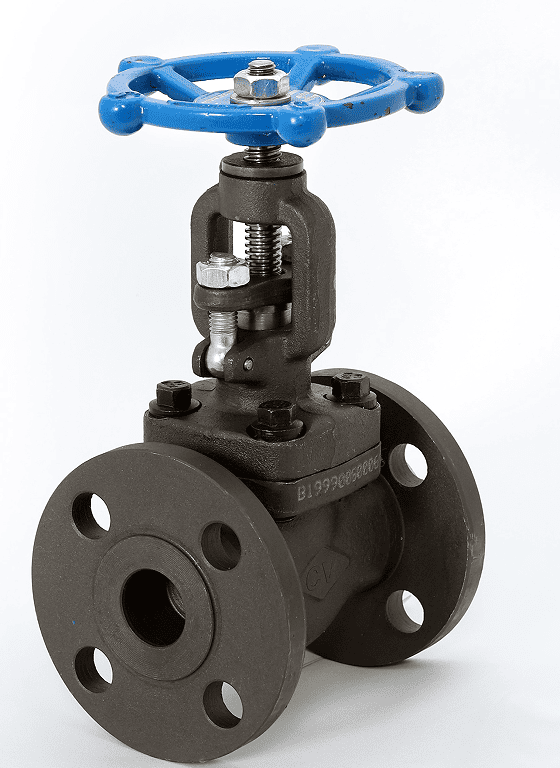

Forged steel globe valves are mechanical devices used to regulate, control, or stop the flow of liquids, gases, or steam in a pipeline. They are constructed from forged steel, a material known for its strength and resistance to extreme conditions, making these valves ideal for demanding industrial environments. The name "globe valve" comes from the spherical shape of the valve body, which houses the internal components responsible for controlling fluid flow.

The primary function of a globe valve is to provide precise flow control and ensure a tight shut-off when needed. Unlike gate valves, which are primarily used for on/off applications, globe valves are designed for throttling and regulating flow, making them indispensable in systems where flow adjustment is critical.

Forged steel globe valves come in several designs, each suited to specific applications and operational requirements. The most common types include:

Y-pattern globe valves are designed with a stem and seat angled at approximately 45 degrees to the pipe axis. This design reduces pressure drop across the valve, making it ideal for high-pressure and high-temperature applications. The Y-pattern configuration also minimizes erosion and wear, extending the valve's lifespan.

T-pattern globe valves feature a traditional globe valve design with a horizontal flow path. These valves are commonly used in applications where flow resistance is not a significant concern. They are suitable for moderate pressure and temperature conditions.

Angle pattern globe valves have an inlet and outlet oriented at a 90-degree angle. This design allows the valve to change the direction of flow while providing efficient flow control. Angle pattern valves are often used in applications where space constraints or piping layout require a change in flow direction.

Forged steel Y-pattern globe valves are a specialized type of globe valve designed to handle high-pressure and high-temperature applications with ease. The unique Y-shaped body design reduces turbulence and pressure drop, ensuring smooth flow control and minimizing energy loss. These valves are particularly effective in systems where precise flow regulation is required, such as in power plants, petrochemical facilities, and oil refineries.

The angled design of the Y-pattern valve minimizes pressure loss, making it more efficient than traditional globe valves.

Constructed from forged steel, these valves are built to withstand extreme conditions, including high temperatures and pressures.

The design allows for accurate throttling and flow regulation, making it ideal for applications requiring fine control.

The reduced wear and tear on the valve components result in lower maintenance requirements and longer service life.

Choosing the right forged steel globe valve for a specific application requires careful consideration of several factors, including operating conditions, fluid properties, and system requirements. Below are the key principles for selecting forged steel globe valves:

Forged steel globe valves are ideal for pipelines or devices handling high-temperature and high-pressure media. Examples include thermal power plants, nuclear power plants, and petrochemical systems.

Globe valves are suitable for pipelines where flow resistance is not a critical factor. They are often used in systems where pressure loss is acceptable or negligible.

Smaller forged steel globe valves, such as needle valves, instrument valves, and sampling valves, are commonly used in applications requiring precise flow control in compact systems.

Globe valves are preferred for applications requiring flow adjustment or pressure regulation, especially in pipelines with smaller diameters (e.g., nominal diameter ≤ 50mm).

In the chemical fertilizer industry, high-pressure angle shut-off valves or high-pressure angle throttle valves with nominal pressures of PN160 (16MPa) or PN320 (32MPa) are recommended.

In the alumina production process, DC-type globe valves or DC-type throttle valves with removable valve seats and carbide seal pairs are used to handle coking and desiliconization pipelines.

In urban water supply and heating systems, smaller pipelines (nominal diameter < 150mm) often use cut-off valves, balance valves, or plunger valves.

Forged steel globe valves are used in a wide range of industries and applications due to their robust construction and reliable performance. Some of the most common applications include:

In thermal and nuclear power plants, forged steel globe valves are used to control the flow of steam and cooling water in high-temperature and high-pressure systems.

These valves are essential for regulating the flow of crude oil, natural gas, and refined products in pipelines, refineries, and offshore platforms.

Forged steel globe valves are used in chemical processing plants to handle corrosive and high-temperature fluids, ensuring safe and efficient operations.

In municipal water supply systems, these valves are used to control the flow of water and other fluids, ensuring reliable and efficient distribution.

Forged steel globe valves are used in heating, ventilation, and air conditioning systems to regulate the flow of hot water, steam, and chilled water.

Forged steel construction ensures that these valves can withstand extreme pressures and temperatures without compromising performance.

Globe valves provide a tight shut-off, preventing leakage and ensuring system integrity.

Available in various designs and sizes, forged steel globe valves can be customized to meet specific application requirements.

The robust construction and high-quality materials used in these valves result in a longer lifespan and reduced maintenance costs.

The design of globe valves allows for accurate flow regulation, making them ideal for applications requiring fine control.

Forged steel globe valves are indispensable components in industries where precise flow control, reliability, and durability are paramount. Their ability to handle high-pressure and high-temperature conditions makes them ideal for demanding applications in power generation, oil and gas, petrochemicals, and water treatment. With designs such as Y-pattern, T-pattern, and angle pattern, these valves offer versatility and efficiency in managing fluid flow. By understanding the selection principles and applications of forged steel globe valves, engineers and industry professionals can make informed decisions to ensure optimal performance and longevity in their systems. Whether in a power plant, refinery, or municipal water system, forged steel globe valves continue to play a critical role in maintaining safe and efficient operations.