Stainless steel globe valves are a vital component in modern industrial piping systems, offering precise flow control, excellent sealing capabilities, and long-term durability in harsh environments. These valves are particularly valued in industries such as petrochemicals, pharmaceuticals, power generation, and food processing due to their resilience and versatility.

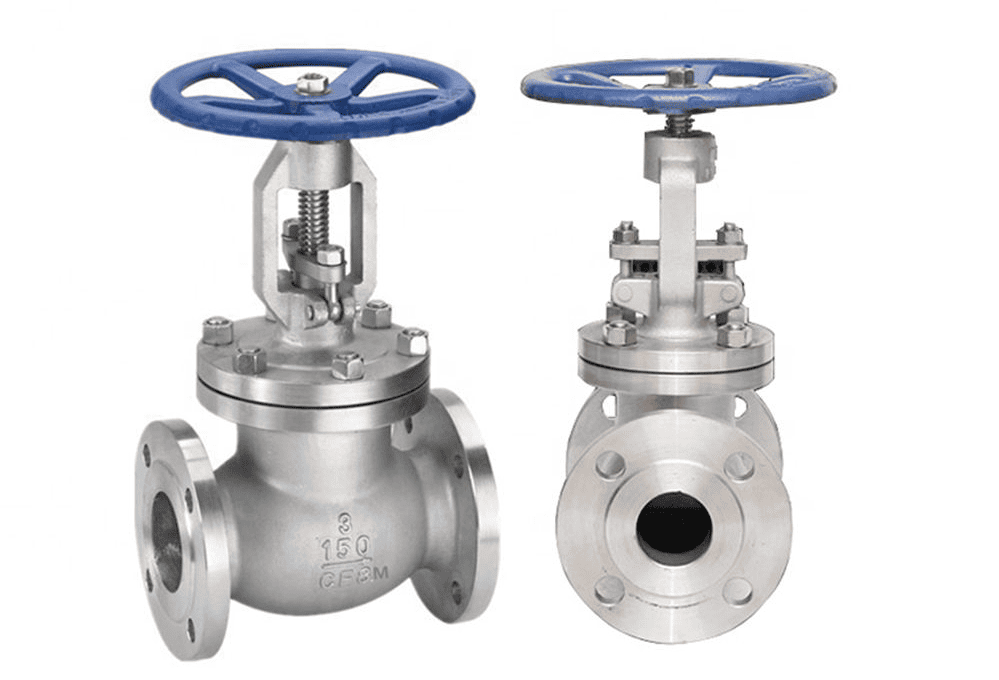

A globe valve operates through a simple yet effective mechanism: a movable disk or plug and a stationary ring seat inside a spherical body. When actuated, the disk moves perpendicular to the fluid flow, allowing the operator to finely control, restrict, or completely shut off the flow of fluids such as liquids, steam, or gas. This direct motion design enables globe valves to excel in applications requiring throttling and frequent operation.

Stainless steel, especially austenitic grades like 304 and 316, is the material of choice for manufacturing these valves due to its superior resistance to corrosion, high temperature strength, and excellent mechanical integrity. This combination makes stainless steel globe valves a reliable solution for processes involving aggressive media, high pressures, and demanding environmental conditions.

This article explores the key features, components, and distinct advantages of stainless steel globe valves, offering insight into why they remain a preferred choice across critical industries worldwide.

Globe valves derive their name from the spherical shape of their body, though modern designs may vary in appearance. Unlike gate valves that are designed for full open or full close operations, globe valves are ideal for regulating flow. Their internal configuration allows the plug to seat precisely against the opening, resulting in tight shut-off and accurate throttling control.

A stainless steel globe valve generally consists of the following key components:

Valve Body: The outer casing of the valve, made from stainless steel, houses all internal parts and endures high pressure and temperature stresses.

Disk (or Plug): The disk is the movable part that regulates fluid flow by seating against the valve seat to restrict or allow passage.

Seat Ring: The fixed internal ring where the disk seals when closed. It may also be made from stainless steel or harder materials like stellite or tungsten carbide for enhanced durability.

Stem: A shaft that connects the handwheel or actuator to the disk. Turning the stem raises or lowers the disk to control the valve.

Bonnet: A cover that provides a sealed housing for the stem and supports stem alignment.

Packing and Gasket: PTFE, graphite, or similar sealing materials prevent leaks around the stem and bonnet areas.

When these components are manufactured using stainless steel, particularly grades like 304, 316, or duplex stainless steel, the valve becomes suitable for even more corrosive and high-stress applications.

To meet the diverse requirements of different industries, stainless steel globe valves are manufactured in several configurations:

This is the most commonly used type. The inlet and outlet ports are aligned in a straight line, with the disk moving vertically to control flow. Ideal for general-purpose throttling and flow regulation.

In this type, the inlet and outlet are positioned at a 90-degree angle. This design simplifies piping layouts in confined spaces and reduces pressure drops compared to the standard pattern.

This design features an angular seat and stem, reducing flow resistance and allowing for higher flow rates. It is often used in high-pressure and high-temperature systems where fluid efficiency is critical.

Engineered with three ports, these valves can be used to mix or divert flows. They are frequently employed in HVAC systems, chemical processing, and systems requiring fluid redirection.

Each type provides distinct performance benefits, and the choice depends on the specific requirements of the system, including space constraints, pressure ratings, flow rates, and operational temperatures.

One of the most critical advantages of stainless steel globe valves is their inherent resistance to corrosion. Austenitic stainless steels, such as 304 and 316, contain chromium and nickel, which form a passive oxide layer that protects against rust and chemical attack. This makes stainless steel valves ideal for systems handling aggressive media, seawater, acids, alkalis, and oxidizing agents.

316 stainless steel, in particular, includes molybdenum, which further enhances resistance to chloride-induced pitting and crevice corrosion, making it a go-to material in marine and chemical industries.

Stainless steel retains its mechanical strength even when exposed to high temperatures and pressures. This makes stainless steel globe valves suitable for steam, high-temperature gases, and thermal oil systems. Their robust design helps maintain tight shutoff and consistent operation under fluctuating thermal conditions.

In addition, stainless steel’s resistance to scaling and oxidation at elevated temperatures ensures longer service life compared to carbon steel or brass alternatives.

Globe valves are known for their tight shut-off capability, and stainless steel enhances this performance through precision machining and dimensional stability. The hard-wearing nature of stainless steel ensures that the seating surfaces do not easily deform or erode, even after frequent cycling. This results in reliable sealing, reduced leakage, and better system integrity.

In applications where leak prevention is critical—such as in pharmaceutical or food-grade processing—stainless steel globe valves offer peace of mind through consistent performance.

Thanks to the material’s strength, wear resistance, and corrosion resistance, stainless steel globe valves require less frequent maintenance and replacement. Even in environments where the valve is opened and closed repeatedly, stainless steel components resist erosion, pitting, and mechanical fatigue.

This translates to longer service intervals, lower lifecycle costs, and reduced downtime in critical processes.

Globe valves are particularly effective for throttling applications because of their linear motion and precise control characteristics. Stainless steel enhances this functionality by maintaining dimensional stability and smooth surface finishes that prevent sticking, galling, or vibration during valve operation.

Whether controlling feedwater, cooling fluids, or compressed air, stainless steel globe valves allow for accurate flow regulation and smooth performance even under varying system loads.

Due to their performance advantages, stainless steel globe valves are widely used in:

Chemical Processing: For handling corrosive fluids and gases.

Oil & Gas: In pipelines, offshore rigs, and refining systems.

Pharmaceuticals: In sterile, hygienic environments requiring cleanability and corrosion resistance.

Food & Beverage: Where sanitary standards and resistance to aggressive cleaning agents are essential.

Power Generation: Particularly in high-pressure steam and cooling water lines.

Their adaptability makes them an ideal choice across both critical and utility applications.

Stainless steel globe valves can be easily adapted for automation with electric, pneumatic, or hydraulic actuators. Their robust construction supports the additional stress of automated operation, which is particularly useful in large-scale or hazardous systems where manual control is impractical or unsafe.

When selecting a stainless steel globe valve, consider the following factors:

Material Grade: Choose between 304, 316, duplex, or other stainless grades based on the chemical compatibility and corrosion resistance required.

Valve Design: Select the appropriate valve type (standard, angle, Y-pattern, or three-way) based on your flow configuration and pressure drop considerations.

End Connections: Options such as flanged, threaded, or socket weld ends should match the pipeline layout and pressure rating.

Pressure & Temperature Ratings: Ensure the valve’s specifications meet or exceed system requirements.

Compliance Standards: Valves should comply with industry standards such as API, ASME, or DIN to ensure compatibility and safety.

Working with a reputable manufacturer ensures quality assurance, availability of spare parts, and technical support for long-term operation.

Stainless steel globe valves represent a combination of engineering excellence and material superiority. Their advantages—ranging from corrosion resistance and high-temperature performance to precise throttling and long service life—make them a dependable choice across a wide spectrum of industrial applications.

Whether you're operating a chemical plant, managing a thermal power station, or installing cleanroom pipelines in a pharmaceutical facility, stainless steel globe valves offer unmatched reliability and efficiency. By choosing the right design and specification for your system, you can ensure optimal flow control, operational safety, and long-term cost savings.