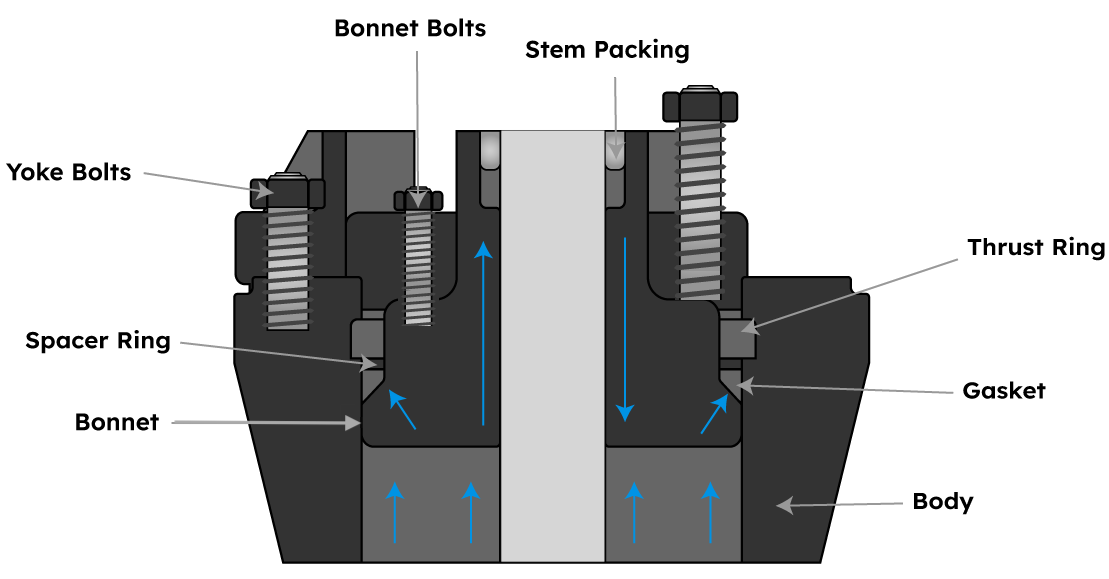

This design feature makes pressure seal valves particularly valuable in applications where fluid leaks could lead to safety risks, environmental damage, or expensive downtime. The ability to maintain a leak-tight seal under high-pressure conditions is why these valves are essential in many critical industries, such as power generation, oil and gas exploration, and chemical production. Pressure seal valves operate through a specialized design that makes use of the pressure in the system to enhance the sealing force. In a typical pressure seal valve, the sealing mechanism consists of a gasket or metal ring that sits between the valve body and the valve bonnet. As system pressure increases, it pushes against the bonnet, causing it to compress the sealing gasket further into the valve seat. This self-energizing action improves the seal, ensuring that no fluid or gas can escape, even in extreme conditions.

The primary advantage of this design is its ability to maintain a secure seal without the need for constant manual adjustments or tightening. This feature makes pressure seal valves highly reliable in high-pressure systems, where the risk of leaks is greatest.

In addition, the sealing mechanism is designed to accommodate temperature variations and fluid flow changes, providing consistent performance even in challenging environments. Whether the pressure fluctuates, or the fluid temperature rises and falls, the valve will continue to perform at its best, providing optimal sealing capabilities.

The primary advantage of pressure seal valves is their exceptional sealing ability. The self-energizing mechanism ensures a tight seal under all pressure conditions, preventing leaks. This makes them ideal for industries where even small leaks could result in catastrophic consequences, such as in the oil and gas sector or in chemical processing plants. The design of the valve improves as pressure increases, meaning that the higher the system pressure, the better the seal, minimizing the likelihood of leakage and ensuring system integrity.

Pressure seal valves are built to last. Constructed from high-quality materials such as stainless steel, alloy steel, and other corrosion-resistant metals, these valves are designed to withstand harsh environments and extreme pressure conditions. Their robust design ensures they can handle continuous operation over long periods without suffering from wear or failure. This durability leads to a longer service life compared to traditional valves, making them a cost-effective choice for industries with high operational demands.

The primary advantage of pressure seal valves is their exceptional sealing ability. The self-energizing mechanism ensures a tight seal under all pressure conditions, preventing leaks. This makes them ideal for industries where even small leaks could result in catastrophic consequences, such as in the oil and gas sector or in chemical processing plants. The design of the valve improves as pressure increases, meaning that the higher the system pressure, the better the seal, minimizing the likelihood of leakage and ensuring system integrity.

Pressure seal valves are built to last. Constructed from high-quality materials such as stainless steel, alloy steel, and other corrosion-resistant metals, these valves are designed to withstand harsh environments and extreme pressure conditions. Their robust design ensures they can handle continuous operation over long periods without suffering from wear or failure. This durability leads to a longer service life compared to traditional valves, making them a cost-effective choice for industries with high operational demands.Additionally, the materials used in pressure seal valves are highly resistant to corrosion, reducing the need for frequent replacements and maintenance. This is particularly beneficial in industries such as oil and gas, where exposure to corrosive substances and harsh environmental conditions is common. One of the standout features of pressure seal valves is their self-adjusting sealing capability. As pressure in the pipeline increases, the valve’s sealing mechanism automatically adjusts to ensure a tighter seal. This self-energizing action reduces the chances of leaks and ensures that the valve continues to perform at its optimal level, even as system pressure fluctuates. This dynamic response to changing conditions makes pressure seal valves highly reliable in industries with unpredictable operating pressures or fluid temperatures. Pressure seal valves are versatile and can be used in a wide range of applications across various industries. Their ability to handle extreme pressures and maintain a secure seal makes them suitable for use in demanding environments such as oil extraction, natural gas pipelines, power generation plants, and chemical processing facilities. In these industries, where pressure levels can fluctuate significantly, the pressure seal valve’s self-adjusting feature ensures consistent performance.

In addition to industrial uses, pressure seal valves are also found in water treatment plants, pulp and paper mills, and HVAC systems. Their flexibility in application makes them a go-to solution for a wide variety of high-pressure fluid handling systems. Pressure seal valves are known for their reliability and minimal maintenance requirements. Their self-adjusting sealing mechanism reduces wear and tear on the valve components, and the high-quality materials used in their construction ensure that the valve remains in service for extended periods without needing frequent repairs. This leads to lower maintenance costs, less downtime, and fewer interruptions in production.

In many cases, pressure seal valves require less attention than traditional valves, resulting in cost savings over the long term. This is especially important in industries where equipment failure can lead to costly shutdowns, loss of production, and potential safety hazards. By installing pressure seal valves, companies can reduce the frequency and cost of maintenance, contributing to overall operational efficiency. Pressure seal valves are used in a variety of industries and applications where high-pressure conditions exist. Some common uses include: