Trunnion-mounted ball valves are widely used in industries requiring precise flow control, from oil and gas pipelines to chemical and water treatment plants. With their unique design, they offer a reliable solution for high-pressure applications, providing better stability and control compared to conventional floating ball valves. This article delves into the structure, operation, and advantages of trunnion-mounted

ball valves, helping you understand how they work and why they’re the preferred choice in demanding environments.

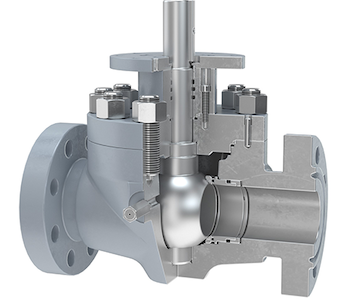

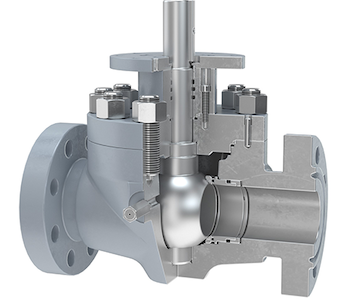

A trunnion-mounted ball valve is a type of quarter-turn valve that regulates the flow of liquids or gases in a pipeline. While standard ball valves use a “floating” ball that’s only connected to the stem, trunnion-mounted ball valves employ a more stable design. In these valves, the ball is fixed in place by two anchoring points: the stem on one side and a trunnion—a shaft that provides additional support—on the other. This structure keeps the ball firmly in position and reduces the torque needed to operate the valve, making it ideal for high-pressure applications.

In a floating ball valve, only one side of the ball is connected to the stem, allowing the ball to move slightly under pressure. This movement presses the ball against the downstream seat, creating a seal. However, in trunnion-mounted ball valves, the ball cannot shift because it is anchored at both ends. This allows for better sealing in both directions and improved performance in high-pressure scenarios, as the ball remains firmly centered within the valve body.

There are several types of trunnion-mounted ball valves, each designed for specific operational needs and conditions:

These valves consist of two or three individual parts, making maintenance easier. Three-piece valves, in particular, allow for convenient disassembly, inspection, and repair, which is essential for critical applications.

In a full-bore valve, the ball has an opening with the same diameter as the pipeline, allowing unrestricted flow. In a reduced-bore valve, the opening is smaller, creating some flow restriction. Full-bore valves are ideal when flow capacity and reduced turbulence are crucial, while reduced-bore valves are typically more cost-effective.

This type of valve includes two seating surfaces, allowing it to seal off pressure from both the upstream and downstream sides. When closed, a bleed valve between the seats releases any pressure buildup, ensuring safety in high-pressure applications.

The operation of a trunnion-mounted ball valve is straightforward. When the valve is open, the ball rotates to align the bore with the pipeline, allowing fluid to flow through without obstruction. When the valve is closed, the ball rotates a quarter turn, positioning the solid part of the ball against the pipeline openings, blocking the flow.

Here’s a more detailed look at how the components of a trunnion-mounted ball valve work together:

Trunnion-mounted ball valves, like other ball valves, are quarter-turn devices. A 90-degree turn of the actuator or handle rotates the ball within the valve body, switching the valve between open and closed states.

The trunnion—a shaft located at the bottom of the valve—provides additional support to the ball. By anchoring the ball at both the stem and trunnion, the valve achieves a stable configuration that reduces the torque needed for operation. This makes the valve easier to operate, especially in high-pressure applications.

In trunnion-mounted ball valves, both upstream and downstream seats are spring-loaded, ensuring tight sealing even under pressure. When the valve is in the closed position, the seats press against the ball to form a seal, preventing any leakage.

For trunnion-mounted ball valves with a double block and bleed configuration, both seats provide an independent seal, blocking pressure from both sides of the valve. This feature is critical for maintenance and safety, as it allows operators to relieve pressure buildup before performing maintenance or repairs.

Trunnion-mounted ball valves offer several benefits that make them suitable for high-demand applications:

The trunnion-mounted design secures the ball at both ends, providing better stability than floating ball valves. This stability makes them less prone to wear and tear, extending the valve’s lifespan even in high-pressure environments.

By anchoring the ball, trunnion-mounted ball valves require less torque to operate, even at high pressures. This feature enables easy actuation and reduces the load on actuators, making them suitable for automated systems.

For applications that demand high safety standards, trunnion-mounted ball valves with double block and bleed configurations provide two independent seals and a bleed valve. This setup ensures there’s no pressure buildup, preventing accidental leaks or spills during maintenance.

These valves can handle a wide range of media, from liquids and gases to viscous fluids and slurries, making them ideal for industries like oil and gas, petrochemicals, and water treatment.

Effective Sealing in High-Pressure Applications: With spring-loaded seats and firm support from the trunnion, these valves maintain a strong seal even under high-pressure conditions, preventing leaks and minimizing the risk of equipment failure.

Trunnion-mounted ball valves are a valuable asset in industries requiring reliable flow control in high-pressure applications. Their unique design—anchoring the ball at both ends—enhances stability, reduces torque, and improves sealing, making them a better choice than floating ball valves in demanding environments. Understanding how trunnion-mounted ball valves work, along with the types and advantages they offer, is essential when selecting the right valve for your specific needs. With their ability to handle high pressures, versatile performance, and robust sealing capabilities, trunnion-mounted ball valves continue to be the go-to solution for industries that require dependable flow control.