There are many types of valves, including ball valves, gate valves,

butterfly valves, globe valves, and safety valves. The opening and closing component of a butterfly valve is a circular butterfly plate, which rotates around a certain axis to control the valve’s operation. A butterfly valve is a multifunctional valve with both cut-off and adjustment functions. Compared to other similar valves, butterfly valves have advantages of light weight, simple structure, fast opening and closing speed, bidirectional sealing, and long service life under harsh conditions. Since China introduced butterfly valves in the 1980s, double eccentric butterfly valves have become widely used after years of research and development. The butterfly valve’s rotation axis deviates to the side of the sealing pair, ensuring the butterfly plate and the valve seat have a complete and continuous sealing surface. The reasonable structure of the double eccentric butterfly valve can meet some high-demand extreme working conditions. Poor design can cause interference during valve operation and excessive driving torque, affecting normal functioning and increasing maintenance costs. In the past, designing double eccentric butterfly valves relied on professionals to conduct theoretical analysis and manual calculations based on reference books. This required a lot of time and energy from researchers and had low accuracy. Especially for large-diameter butterfly valves, calculations are time consuming. With the rapid development of computer technology, computer-aided design has been widely used in mechanical design, which greatly improves the design accuracy and efficiency of double eccentric butterfly valves and reduces the errors and time costs of manual calculations. Computers can perform three-dimensional modeling and simulation analysis to help designers better understand and optimize their designs. Conducting structural optimization research on double eccentric butterfly valves and developing optimization design software are essential. Developing software can provide reliable technical support for design and applications of butterfly valves.

History and development of butterfly valves

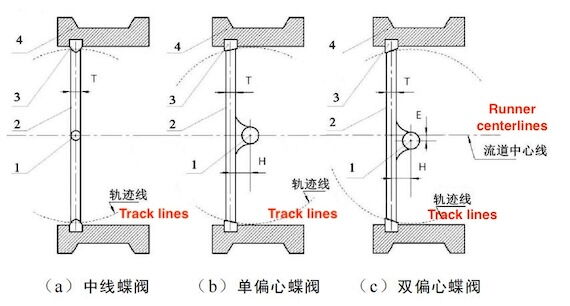

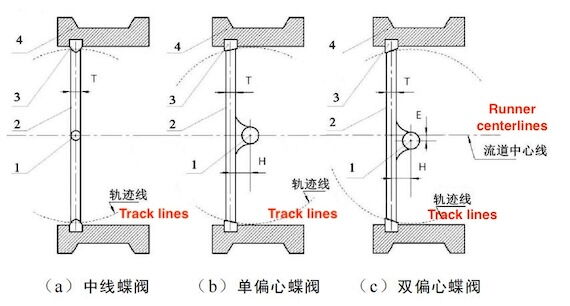

With the continuous research and improvement of butterfly valves, butterfly valves have developed from the original centerline butterfly valves to many types, such as single eccentric butterfly valves, and double eccentric butterfly valves. The rotation center of butterfly plates is located on the cross section between valve body centerlines and butterfly plate sealing surfaces, as shown in figure 1(a). This structure has advantages of easy manufacturing and installation. However, during operation, the sealing surface of the butterfly plate is always in contact with the valve seat and is squeezed, causing the sealing pair to be scratched and worn, affecting the sealing performance. This type of butterfly valve also only uses synthetic rubber as the valve seat material to produce elastic deformation and form elastic force, ensuring sealing performance, reducing applicability and requiring a large driving torque for operation. The rotation center of the single eccentric sealing butterfly valve plate is located on the center line of the valve body, forming an offset dimension H with the butterfly plate sealing section and a complete sealing ring surface, as shown in figure 1 (b). It is easy to ensure the roughness of the butterfly plate and the valve seat surface during processing, and effectively disperse the problem of excessive extrusion of the sealing pair, but the effect is still not ideal. Based on the improvement in the single eccentric sealing butterfly valve, the double eccentric sealing butterfly valve is now widely used in various fields, and the structure is shown in Figure 1(c). The butterfly plate rotation axis is not only offset by dimension H from the butterfly plate sealing section, but also offset by dimension E from the valve body channel axis. The rotation radius of the butterfly plate becomes a long radius and a short radius. When the valve is opened and closed, the butterfly plate sealing surface gradually separates and squeezes relative to the valve seat sealing surface, and the butterfly plate sealing surface separates from the valve seat sealing surface faster than the single eccentric butterfly valve. When the butterfly plate rotates from 0° to 12°, the butterfly plate sealing surface can completely separate from the valve seat sealing surface and form a larger gap, further reducing the mechanical wear between the butterfly plate and the valve seat, greatly improving the valve sealing performance and service life.

(a) Centerline butterfly valves (b) Single eccentric butterfly valves (c) Double eccentric butterfly valves

1. Valve shafts 2. Butterfly plates 3. Valve seats 4. Valve bodies

T. Sealing surface thickness H. Axial eccentricity E. Radial eccentricity

Figure 1 Structural diagram of three types of butterfly valves

Thanks to the accurate calculation, rigorous design and precision manufacturing of many experts, scholars, and enterprises, today's valve industry is booming and thriving. The development of double eccentric butterfly valves is constantly improving and self-perfecting to achieve the goals of non-interference, zero leakage and small torque. Foreign countries are more proficient in using butterfly valves and have conducted a lot of research on their sealing performance. These butterfly valves can operate in harsh environments. In 1960, Karl Adams Company in Germany proposed that butterfly valves have three functions: cut-off, regulation, and non return. In 1966, the company registered a patent called "inclined conical seat sealing systems", marking an important step forward in butterfly valve technology. Kerl and others conducted experimental research on the flow field of butterfly valves and wrote corresponding flow field analysis reports. Sarpkara conducted theoretical research on the flow characteristics of butterfly valves, thereby providing a theoretical basis for their flow states. Kimura and Tanaka focused on the pressure loss of some special butterfly valves. Nowadays, with the rapid development of computer technology, software development has become mature, providing new calculation tools for research on butterfly valves. Lin and Schohl used computer software to conduct a feasibility analysis in solving butterfly valve problems, confirming the importance of computer software in the field of butterfly valve research.

Huang and Kim used (CFD) fluid dynamics simulation computer software to simulate the flow state of incompressible fluid inside a butterfly valve and obtained the velocity, temperature and pressure cloud diagrams of the internal fluid flow. Park Youngchul and Song Xueguan used computer software (CFX) to perform numerical simulation, studied the hydrodynamic torque of a butterfly valve, and analyzed the relationship between the hydrodynamic torque coefficient and the flow resistance coefficient. A.D.Henderson used computer software to solve the flow characteristics of some special safety butterfly valves. Kazuhiko and Koichi used CFD software to study and simulate the cavitation problem of butterfly valves, providing a new method that enables people to intuitively understand the cavitation phenomenon and solve this problem. Zachary and Charles conducted a preliminary study on the opening and closing torque of butterfly valves. Bella simulated the acoustic vibration of butterfly valves. Villouvier established and analyzed the acoustic wave propagation model of butterfly valves, making an important contribution to solving the noise problem of butterfly valves. Peiman Naseradinmousavi and others analyzed the rotation torque of butterfly valves. By establishing a dynamic analysis model and using operation of the electromagnetically driven eccentric butterfly valve, they concluded that the driving torque plays a vital role in the butterfly plate’s operation. Foreign researchers mainly use experiments and simulations as the main means. By comparing numerical simulations with experimental results, they deeply analyze the flow characteristics of the internal structure of the butterfly valve, providing a new research method for people to study the internal structure of the butterfly valve and the movement of the fluid, and providing a new reference for the design of eccentric butterfly valves.

Since China introduced butterfly valves, their applications are continuously explored. Nowadays, many new eccentric butterfly valves have emerged independently developed, which are increasingly widely used.