The polycrystalline silicon pipeline trunnion ball valve is a remarkable engineering marvel that has revolutionized the field of pipeline technology. This valve, made from polycrystalline silicon, offers unparalleled strength and durability, making it an ideal choice for high-pressure applications. One of the key features of this valve is its trunnion design. The trunnion ball valve consists of a rotating ball with a hole in it, which allows for precise control over the flow of fluids or gases. The polycrystalline silicon material used in its construction ensures that the valve can withstand extreme temperatures and pressures without compromising its integrity. Furthermore, the polycrystalline silicon material also provides excellent resistance to corrosion and abrasion, making it suitable for use in harsh environments. This makes the valve highly reliable and long-lasting, reducing maintenance costs and downtime. In addition to its exceptional performance characteristics, the Polycrystalline Silicon Pipeline Trunnion Ball Valve also offers ease of operation. Its innovative design allows for smooth and efficient opening and closing actions, ensuring minimal energy loss during operation. The material selection and treatment process, structure and other aspects of the trunnion ball valves on the device pipelines during the production and purification process of polysilicon are introduced in this article.

4. Design and optimization of trunnion ball valve structure

4.1 Structural analysis

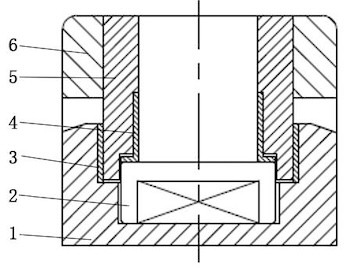

The working conditions of polysilicon devices and pipelines are special, with complex media such as dust particles, high temperatures, oxidation, hydrogen embrittlement, strong corrosiveness, etc. In addition to the rational selection of materials, the rational optimization of structural design also ensures that the metal seated polysilicon wear resistant trunnion ball valve has good sealing and service life and is not blocked. The structure of the polysilicon pipeline trunnion ball valve is shown in Figure 2.

Figure 2 Structural diagram of polysilicon pipeline trunnion ball valves

4.1.1 Design of valve stem bushing

Polycrystalline silicon pipeline metal seated wear-resistant trunnion ball valves have a metal seat and an imported valve seat seal. The medium sealing force acts on the upper and lower sleeves. The load on the upper and lower sleeves is very great, and the opening and closing are frequent, with an angular stroke of 90 degrees; the opening and closing speed is fast.

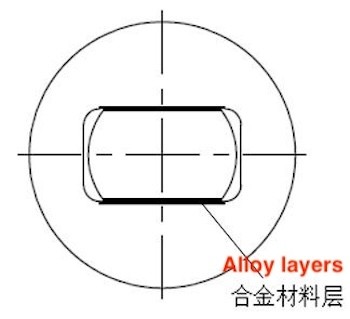

The sleeves can easily damage the valve stem and the lower fixed shaft, causing the torque to increase and open and close the valve. In response to this situation, a wear-resistant bushing should be designed. The flat surface and inner hole of the bushing should be sprayed with wear-resistant alloy hard materials, which can effectively prevent the valve stem from being damaged. The design of the valve stem’s wear-resistant bushing is shown in Figure 3.

1. Balls 2. Valve stems 3. Upper cover sleeves 4. Valve stem sleeves 5. Upper covers 6. Valve bodies

Figure 3 The structure of the valve stem bearing

4.1.2 Optimization of the connection between the valve stem and the ball

The medium of polysilicon pipeline metal seated trunnion ball valves is dust. The ball valve torque is great, and it is opened and closed frequently when used as an air flow delivery valve in polysilicon devices and pipelines. At the connecting part between the valve stem and the ball, it is easy to cause the valve stem or the stress surface of the ball to be easily squeezed and deformed due to insufficient hardness, resulting in a larger opening and closing angle, and opening and closing of the ball valve cannot reach the designed position, causing leakages of ball valves. The hardness of the flat square of the valve stem can be increased by high-frequency quenching at the flat square of the valve stem. At the same time, the surface hardness of the flat square of the sphere can be improved by surfacing or spraying an alloy material that improves the hardness of the stress-bearing surface of the flat groove of the sphere, thereby improving extrusion resistance. This solution optimizes the torque transmission between the valve stem and the ball, solves the problem of deformation at the connection part between the valve stem and the ball, and improves the service life of the valve. The connection design between the valve stem and the ball is shown in Figure 4.

Figure 4 The connection part between the valve stem and the ball

The key processes such as the production and purification of polysilicon are complex, and the working conditions of the equipment and pipelines are harsh. The design optimization scheme of metal seated trunnion ball valves for polysilicon pipelines introduced in this article is a practical optimization scheme used in multiple polysilicon devices and pipelines. Product performance and service life meet the user's working conditions needs. The metal seated trunnion ball valve with this structure is used in other working conditions, such as coal chemical industry, coal slurry, slag locking, slag discharge, black water and other working conditions, and it also meets the requirements of the working conditions.