In the world of industrial flow control, precision, efficiency, and durability are essential. Valves are at the core of this functionality, and among the many types available, the angle type globe valve stands out as a smart, space-saving, and performance-enhancing solution. This article takes a deep dive into the angle globe valve—how it works, what sets it apart, and where it excels in industrial applications.

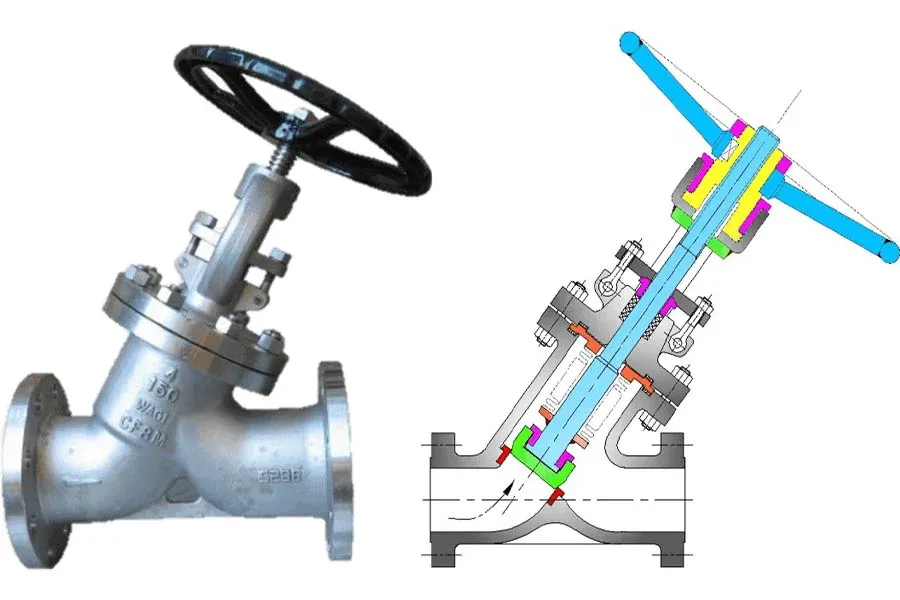

An angle type globe valve is a variant of the standard globe valve. The fundamental difference lies in its configuration: while traditional globe valves feature a straight-line design, angle globe valves are constructed with the inlet and outlet ports positioned at a 90-degree angle. This clever design simplifies pipe routing and reduces the need for additional pipe fittings, such as elbows.

At its core, the angle globe valve operates just like a conventional globe valve. It has a globe-shaped body and a movable disk (or plug) that moves perpendicular to the flow path to regulate or shut off fluid. The angular configuration introduces an efficient directional change in the flow, reducing turbulence, lowering pressure drops, and optimizing energy use within a piping system.

The operation of an angle globe valve is based on a time-tested mechanical principle that enables precise control over fluid flow. Here’s a breakdown of the core components and how the valve functions:

The valve body is the structural shell that houses all internal components. In an angle globe valve, this body features inlet and outlet ports arranged at a 90-degree angle. This right-angle design is highly advantageous for piping systems requiring a change in flow direction or where space constraints exist.

The unique shape eliminates the need for an external elbow, reducing the total number of joints in the piping system, minimizing potential leak points, and simplifying installation.

At the heart of the valve’s operation is a disk or plug that presses against a stationary valve seat to restrict or allow fluid flow. The disk is connected to a stem, which, in turn, is actuated by a handwheel, electric motor, or pneumatic actuator.

When the disk is lowered onto the seat, the valve closes, effectively blocking fluid flow.

When the disk is lifted off the seat, fluid is allowed to pass through the valve and exit at a 90-degree angle.

This movement is typically linear, enabling precise modulation of flow, unlike quarter-turn valves that offer only on/off functionality.

One of the greatest strengths of globe valves—especially the angle type—is their throttling capability. Because the flow is directed perpendicularly through the valve body and regulated by a modulating disk, operators can finely adjust the rate of flow to meet system demands.

This level of control makes angle globe valves ideal for applications requiring consistent and accurate fluid regulation, such as in steam systems, chemical dosing lines, and cooling circuits.

Leak prevention is critical in industrial systems, especially when working with hazardous or high-pressure fluids. Angle globe valves are equipped with robust sealing systems, often featuring materials such as PTFE (Teflon), graphite, or elastomers, depending on the medium and temperature range.

When the valve is closed, the disk makes firm contact with the valve seat, forming a tight seal that prevents leaks and reduces the risk of backflow.

Despite the 90-degree turn in the flow path, the valve's internal geometry is carefully designed to be as streamlined as possible, minimizing turbulence and energy loss. Compared to traditional globe valves, angle globe valves offer improved flow dynamics, particularly in high-pressure applications.

The compact right-angle design allows these valves to be installed where space is limited or where the piping system requires a turn. This eliminates the need for a separate elbow fitting, saving both space and installation time.

Thanks to the shorter and more direct flow path, pressure drops are minimized, and energy efficiency is improved. This is especially important in systems where maintaining flow velocity and minimizing head loss is crucial.

Angle globe valves can be installed at points where the fluid direction needs to change—such as corners of piping systems—reducing complexity and the need for additional fittings.

As with all globe valves, the angle version offers superior control over flow rates, making it suitable for both on-off and throttling services.

Understanding the differences between angle and standard globe valves helps in selecting the right valve for the right application. Here’s a detailed comparison:

|

Feature |

Standard Globe Valve |

Angle Globe Valve |

|

Design Orientation |

Straight-through flow, valve body aligns with pipeline |

Inlet and outlet form a 90° angle |

|

Flow Path |

Complex, includes multiple changes in direction |

Simpler with one directional change |

|

Pressure Drop |

Higher due to longer flow path |

Lower due to shorter flow path |

|

Space Requirements |

Larger, needs more room for piping and elbows |

Compact, especially in corners |

|

Installation |

Requires two elbows for directional changes |

Only one valve needed |

|

Application |

General industrial use |

Ideal for tight spaces, efficient fluid direction change |

|

Turbulence |

More turbulence due to turns in flow |

Reduced turbulence |

Because of their robust construction and efficient flow dynamics, angle globe valves are widely used across various industries, including:

Used for throttling or regulating high-pressure steam, oil, or chemicals where space and flow efficiency are critical.

Ideal for boiler feedwater control, steam regulation, and other high-pressure, high-temperature services.

Excellent for corrosive fluids, particularly when fluoropolymer-lined or built from corrosion-resistant alloys.

Helps in controlling chilled water, condenser loops, or steam in confined mechanical rooms.

Used in water and chemical distribution systems due to its robust throttling capabilities.

Angle globe valves are available in a wide range of body materials, such as:

Carbon steel (for general applications)

Stainless steel (for corrosive environments)

Bronze or brass (for marine and water applications)

Special alloys like Hastelloy, Monel, or duplex steel for highly corrosive or high-temperature environments

They also come in different seat materials and end connections, including:

Flanged

Threaded

Socket weld

Butt weld

Angle globe valves can be operated in several ways depending on system requirements:

Manual Operation via handwheels, suitable for low-frequency adjustments.

Electric Actuators, ideal for automated control in systems requiring precision and integration into SCADA systems.

Pneumatic Actuators for quick and reliable operation in high-cycle or hazardous environments.

The type of actuator can impact the valve’s responsiveness, installation footprint, and overall system automation level.

Like all control valves, regular inspection and maintenance are key to ensuring long-term reliability. Fortunately, angle globe valves are generally easy to service thanks to their accessible internal components.

Tips for Maintenance:

Regularly inspect the valve seat and disk for wear or erosion.

Ensure the stem and actuator operate smoothly.

Check seals for aging or cracking.

Clean the internal components if operating in dirty or sediment-laden fluids.

The angle type globe valve represents a powerful evolution in valve technology, merging the precision of traditional globe valves with the practical advantages of a 90-degree flow path. Its space-saving design, enhanced flow efficiency, and robust control capabilities make it a favored choice in modern industrial piping systems.

From chemical processing plants to power generation stations, this valve type proves to be a reliable and efficient solution, especially where flow redirection and precise throttling are crucial.

By understanding how angle globe valves function, where they shine, and how they compare to conventional designs, engineers and system designers can make more informed choices that improve performance, reduce maintenance costs, and ensure long-term reliability.