Gate valves are fundamental components in industrial and municipal systems, playing a vital role in regulating the flow of liquids and gases. Recognized for their ability to provide a secure seal when fully closed, gate valves are widely utilized in pipelines, water supply networks, oil and gas operations, and chemical processing plants. Their primary function is to either completely stop or allow the unimpeded flow of fluids, making them indispensable in applications requiring reliable isolation.

This article explores the working principle of gate valves, their key applications across industries, and best practices for maintenance to ensure optimal performance and longevity.

A gate valve, also known as a sluice valve, is primarily used for on/off flow control in pipelines. It features a gate-like closure element that moves vertically within the valve body. Turning the handwheel multiple times raises or lowers the gate via a threaded stem. When the gate is fully lifted, it creates an unobstructed path for fluid or gas to pass through; when lowered, it completely blocks the flow.

Gate valves are not intended for throttling or regulating flow. This is because the flow rate changes non-linearly as the gate opens or closes—most of the flow adjustment occurs near the closed position. Operating the valve in a partially open state can cause high-velocity flow to erode the gate and seat, potentially leading to premature wear, vibration, and failure.

Due to their ability to provide a tight seal and full flow when open, gate valves are widely used in applications that require isolation, such as in water supply systems, oil and gas pipelines, and other industrial fluid-handling processes.

On/Off Function: Gate valves are designed primarily for fully open or fully closed operation, not for flow regulation.

Minimal Flow Resistance: When fully open, the gate retracts entirely into the valve body, allowing unrestricted flow with minimal pressure drop.

Bidirectional Flow: Most gate valves can handle flow in either direction, though some specialized designs may have directional preferences.

Tight Seal: The gate presses firmly against the valve seats when closed, preventing leakage.

Gate valves derive their name from the "gate" mechanism that slides into the flow path to block or permit fluid passage. They are commonly used in:

Water distribution networks (municipal and industrial)

Pipeline isolation during maintenance or repairs

Flow diversion in complex piping systems

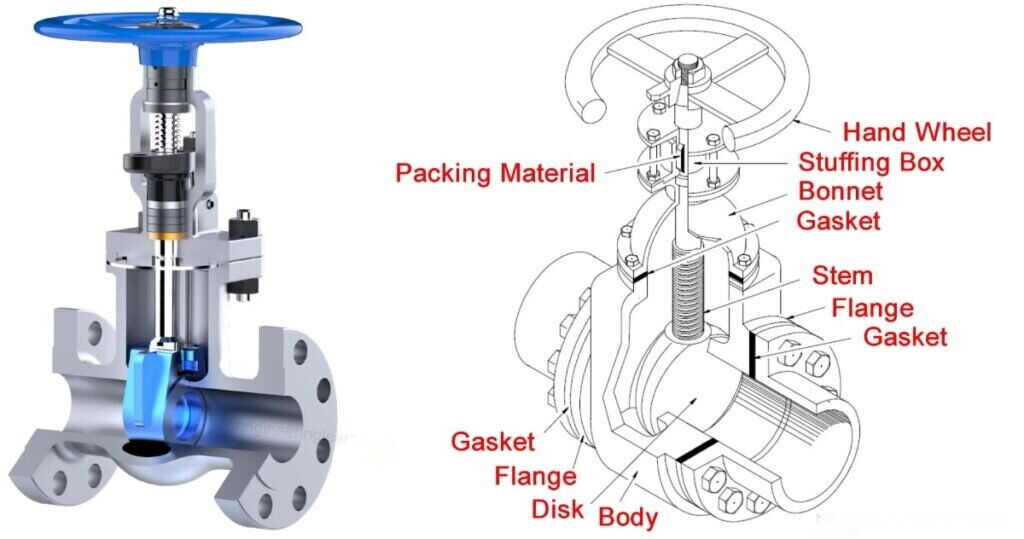

Gate valves operate using a simple yet effective mechanism. The primary components include:

Body: The outer shell housing the internal parts.

Bonnet: The cover that seals the valve body and contains the stem assembly.

Gate (Disc): The movable barrier that blocks or allows flow.

Stem: A threaded rod that connects the handwheel to the gate, transmitting motion.

Handwheel/Actuator: The manual or automated mechanism used to open or close the valve.

Rotating the handwheel counterclockwise raises the stem, lifting the gate out of the flow path.

In automated systems, an actuator (electric, pneumatic, or hydraulic) drives the stem movement.

Once fully open, the gate is completely recessed, allowing unobstructed flow.

Turning the handwheel clockwise lowers the stem, forcing the gate down into the valve seat.

The gate forms a tight seal against the seats, preventing fluid passage.

For underground or hard-to-reach installations, an extension spindle is often used to operate the valve from the surface.

Gate valves are widely used across numerous industries due to their robust design and effective on/off control capabilities. Their ability to provide minimal flow resistance when fully open makes them ideal for isolation applications. Below are key areas where gate valves play a vital role:

Gate valves are commonly used in municipal water supply networks to isolate pipeline sections during maintenance or new installations. They also help regulate flow in residential, commercial, and industrial distribution systems. In agriculture, gate valves manage water delivery in irrigation systems, ensuring efficient and controlled water usage.

In the oil and gas sector, gate valves are crucial for pipeline shutoff and flow control in refineries and processing plants. They can withstand high pressures, making them suitable for transporting crude oil, natural gas, and refined products. Offshore drilling operations rely on gate valves in subsea systems for their durability and reliability in demanding environments.

Gate valves used in chemical plants are often made from corrosion-resistant materials like stainless steel or alloys. These valves handle aggressive or hazardous chemicals safely and are essential for isolation in the event of leaks or spills.

Thermal and nuclear power plants use gate valves in high-temperature steam lines and cooling water systems. They ensure safe and efficient control of fluids in boilers, turbines, and condensers.

Gate valves are found in sewage and stormwater systems, handling sludge and treated water efficiently. They help prevent backflow and manage flow during peak drainage events.

In marine applications, gate valves control water flow in ballast systems and fuel lines. They are essential for managing fluids in confined, high-pressure environments aboard ships.

Proper maintenance ensures longevity, reliability, and leak-free operation. Neglecting upkeep can lead to seizure, corrosion, or failure, causing costly downtime.

Check for external leaks around the bonnet, stem, and body.

Inspect packing glands (seals around the stem) for wear and repack if necessary.

Look for corrosion or mineral deposits, especially in water systems.

Apply valve grease to the stem threads to prevent sticking.

For buried valves, use corrosion-resistant lubricants.

Cycle the valve fully open and closed periodically to prevent seizing.

Ensure smooth handwheel operation—excessive force may indicate internal damage.

Pressure tests can identify internal leaks.

Replace damaged seats or gates if sealing performance declines.

Keep spare valves in a dry, clean environment.

Protect threads and sealing surfaces from damage during transport.

| Problem | Possible Cause | Solution |

|---|---|---|

| Valve won’t open/close | Corrosion, debris, seized stem | Lubricate, clean, or replace stem |

| Leakage when closed | Worn gate or seat | Resurface or replace sealing components |

| Stem leakage | Damaged packing | Repack or replace gland seals |

Gate valves are indispensable in industries requiring secure flow isolation. Their simple yet robust design makes them ideal for high-pressure, high-temperature, and corrosive environments. From water supply networks to oil pipelines and power plants, these valves ensure safe and efficient operations.

By following proper maintenance protocols, operators can maximize valve lifespan and prevent failures. Whether manual or automated, gate valves remain a cornerstone of modern fluid control systems, offering reliability when full shutoff is critical.

For optimal performance, always select the right valve material, size, and type for your application and adhere to scheduled maintenance routines.