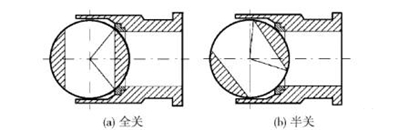

The ball and valve seat of the ordinary ball valve are always in contact and there is friction when it is fully closed, half opened and fully opened. See figures 1 (a), 1 (b) and 2 (a).

Figure 1 Two working states of ordinary ball valves

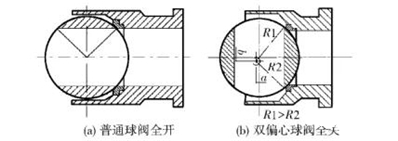

1.2 Double eccentric ball valves (Figure 2(b) and 3)

Figure 2 A comparison between ordinary ball valves and double eccentric ball valves

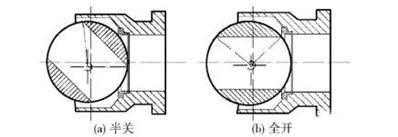

Figure 3 Two working states of double eccentric ball valves

(1) Figure 2(b) shows the fully closed state of double eccentric ball valves. When the sphere rotates, the sealing surface of the sphere shifts relative to the original geometric center due to the eccentric distance of a and b. The distance from the center of rotation to the sealing surface of the valve seat varies with different positions, and there is a long and short radius, that is, R1 being greater than and equal to R2.

(2) Figure 3(a) shows the opening of double eccentric ball valves. When the sphere rotates to a certain angle, a cam effect occurs due to the long and short radius. At this time, the sphere and valve seat begin to separate, and they rotate without friction.

(3) Figure 3(b) shows the fully opened state of double eccentric ball valves. When the ball rotates to 90 degrees, the ball and valve seat are completely separated. There is no friction between the ball and valve seat, and the ball channel and valve body channel are directly connected. The two eccentricities are required to be equal to ensure that the centers of the two channels coincide, that is, a being equal to b. At this time, the angle between the line from the rotation center to the center of the ball and the center of the channel is exactly 45°, which causes a special problem for the double eccentric ball valve. Because the two eccentric structure of double eccentric ball valves must be equal, when the long radius R1 passes through the center of the sphere and falls within the sealed spherical surface area, R1 is tangent to the sealed spherical surface at this time. Great sliding friction will occur near the tangent point, which makes the partial friction of the ball valve more serious and accelerates the wear. Because the best sealing area of the ball valve is generally at the position where the angle between R1 and the center of the channel is 45°. The double eccentric ball valve is often scratched at this position during testing or use.

1.3 Triple eccentric ball valves

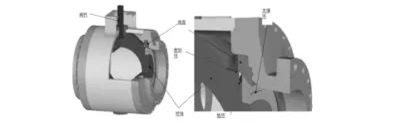

An eccentricity is provided for the triple eccentric metal seated ball valve on the basis of the double eccentric metal seated ball valve. The three-dimensional model of its structure is shown in Figure 4. There are two types of triple eccentric ball valves, namely spherically sealed and conically sealed triple eccentric ball valves.

Figure 4 The three-dimensional model of the sealing structure

The sealing ring of the spherically sealed triple eccentric ball valve is a spherical surface, and the sphere center of this spherical surface does not overlap with that of the double eccentric ball valve, resulting in a third eccentricity. This eccentricity changes the geometric relationship between R1 and the sealing sphere, making R1 not be tangent to the sealing sphere even if it passes through the double eccentric sphere. This overcomes the inherent shortcomings of the double eccentric ball valve. By changing the spherical sealing ring into a conical sealing ring, a triple eccentric ball valve with conical sealing can be obtained.

2. Advantages of triple eccentric ball valves

2.1 Comparing triple eccentric ball valves with ordinary soft sealed ball valves

(1) Triple eccentric ball valves have a wider temperature range. Soft sealed ball valves are affected by the temperature resistance of non-metallic seals and cannot be used in situations where the temperature is too high. The metal seal can be used at a temperature of 600℃ or above according to different materials.

(2) Triple eccentric ball valves can be used for higher pressure. Limited by non-metallic materials' pressure resistance and stability under high pressure, non-metallic sealed ball valves are used for pressure with CL600 or lower. When used at high pressure, non-metallic seals are easy to lose stability and cause the failure of valves. The metal hard sealed ball valve can be used in pressure CL2500.

(3) Triple eccentric ball valves can have a longer service life. Compared with metallic materials, non-metallic materials are prone to aging. Therefore, after using for a period of time, the sealing performance of the valve will also decrease due to the decrease in the performance of non-metallic materials. Moreover, non-metallic materials are susceptible to damage. When the fluid contains solid particles, the non-metallic seals are easily scratched, resulting in seal failure or reduced sealing performance.

2.2 Comparing triple eccentric ball valves with ordinary metal hard seated ball valves

(1) The ball of triple eccentric ball valves is fixed. The ordinary ball valve has a floating ball seal, while the triple eccentric ball valve has a fixed ball design, and its seal specific pressure is established by its own torque. Therefore, it is reliable under any circumstances.

(2) Triple eccentric ball valves have a torque seal design. The traditional metal hard sealed trunnion mounted ball valve usually has a pre-compression spring behind the valve seat. Under the action of the spring, the valve seat is in contact with the sealing surface of the ball and forms seal specific pressure. If the spring's stiffness is poor, the seal has smaller specific pressure and a poor sealing effect. If the spring's stiffness is great, it will increase the wear of the sealing surface and the opening and closing torque at the same time. Moreover, the spring is affected by the temperature of the medium, and its stiffness tends to change with time. Therefore, the sealing effect will also change with time. The triple eccentric ball valve is sealed by torque, which can form a greater sealing pressure without serious wear, and it is not affected by temperatures and alternating loads.

(3)Triple eccentric ball valves have two-way sealing performance of a single valve seat. Under low-temperature conditions, the traditional metal hard sealing ball adopts a complicated automatic pressure relief mechanism or boring in order to release the medium in the valve cavity. The former increases the complexity of the valve seat, and the latter makes the ball valve directional due to the boring. The triple eccentric ball valve adopts a single valve seat, so there is no problem for valve cavities to release pressure. The triple eccentric structure makes the sealing of the valve seat good no matter which direction it is, that is, it has a complete two-way sealing function.

3. The design of triple eccentric ball valves

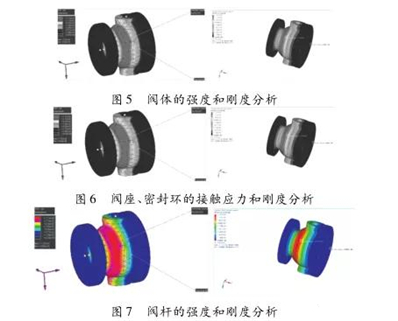

3.1 Use the finite element analysis to specifically design strength and stiffness, which includes: the analysis of strength and stiffness of the valve body (Figure 5), contact stress and stiffness of the valve seat and sealing ring (Figure 6), strength and stiffness of the valve stem (Figure 7).

3.2 Speaking of the processing of the sealing surface of the sealing ring and valve seat for triple eccentric ball valves, whether it is a conical surface seal or a spherical surface seal, the processing of the sealing ring is the key and requires special tooling. The machining accuracy of the sealing surface directly affects the final performance of the valve.

In summary, the metal seated triple eccentric ball valve can be applied to the following conditions:

- High-temperature working conditions (up to 600 ℃)

- Low-temperature or ultra-low temperature working conditions (-196 ℃)

- High-pressure working conditions (available to CL2500)

- Working conditions with hydrogen

- Solid particles