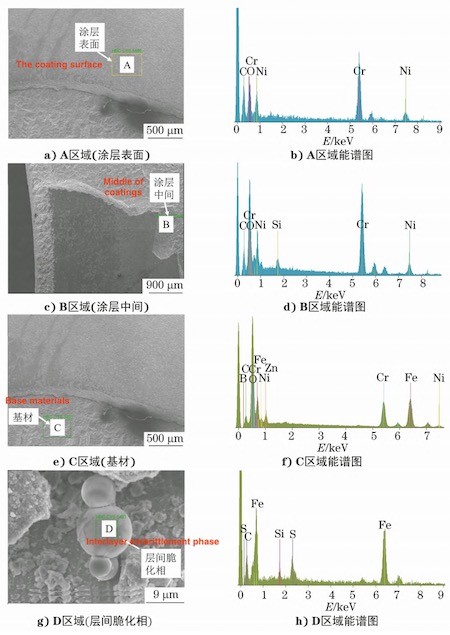

Energy spectrum analysis was performed on the original coating area, cracked coating area and peeled base material area on the surface of the ball valve. The results are shown in Figure 3. The mass fraction of Ni element in the coating surface layer is 10%, Cr 25% to 40%, and Fe 0 to 5%. The composition of the middle area of the broken coating is the same as that of the complete coating surface. It is a high-impact and corrosion-resistant high-chromium nickel coating. The mass fraction of Ni in the ball valve base material is 0 to 2%, Cr 10% to 15%, and Fe 20% to 30%, indicating that the base material of the ball valve does not contain Ni and iron-based materials.

Figure 3

a) The area A (coating surfaces)

c) The area B (middle of coatings)

e) The C area (substrate)

g) The area D (interlayer embrittlement phase)

b) Energy spectrum of the area A

d) Energy spectrum of the area B

f) Energy spectrum of the area C

h) Energy spectrum of the area D

The chemical composition of the coating and the base material is quite different, indicating that there is no element migration between the flame spray coating and the ball valve base material, that is, there is no interpenetration of liquid metal with the base material, and it is a mechanical bond rather than a metallurgical bond. The spherical precipitated components between the coating and the substrate are Fe and C elements, which are interlayer carbides precipitated under high temperatures. It can be seen that the base material is non-austenitic stainless steel with low Ni element content, and the flame spray coating is a cemented carbide with high Cr and Ni element content. This alloy has greater brittleness. The high-frequency movement of the valve stem causes the ball valve to crack and peel under stress.

2. Comprehensive analysis

According to the above analysis, it can be concluded that the base material of the ball valve is low alloy steel 12Cr1 MoV, and the flame spray coating is NiCr-CrsC2 cemented carbide with high Cr and Ni element content. At the same time, the two are in a mechanically bonded state. The coating and the base material are two independent parts. There is no element flow caused by the mutual melting process of the base metal and the coating metal. Therefore, there is a big gap in the bonding strength between the two compared to the metallurgical bonding.

The ball valve is flame sprayed on the entire ball before mechanical processing, and rectangular groove processing is performed after spraying is completed. According to GB/T 3077-2015, the hardness of the base material 12Cr1MoV steel is not greater than 179 HBW and its resistance to deformation is low. Under the action of the alternating stress caused by the high-frequency reciprocating motion of the valve stem, cyclic stress occurs on the hinge surface of the valve stem and the ball valve, so obvious deformation occurs in the rectangular groove of the ball valve. Under the cyclic action of alternating stress, the surface coating forms a fatigue source and becomes unstable and expands, which is the direct cause of the cracking of the surface coating of the ball valve.

NiCr-CrsC2 coating is a brittle metal-based ceramic coating. It is a metal-based ceramic composite material. It is mechanically bonded to the matrix through thermal spraying. The mechanical bonding strength is about 90MPa. The surface modification intensity is quite different from that of metallurgical bonding forms such as plasma spray welding and laser cladding. After being subjected to alternating stress, the coating is prone to peeling and falling. At the same time, the ball valve operates at a high temperature of about 480°C. A carbon-containing spherical phase mainly composed of MasCo and M, C precipitates between the 12CrIMoV steel substrate and the NiCr-CrsC2 coating, resulting in the bonding between the substrate and the coating not being bonded well and exacerbating the peeling effect.

3. Conclusion

(1) It is recommended that the groove of the ball valve be machined first, and then flame sprayed so that the spray coating can cover the inside of the groove and ensure the hardness and deformation resistance of the ball valve and the valve stem at the rotation stress point.

(2) After the ball valve is machined with grooves, the stress area is determined according to the deformation point of the ball valve, and the inner hole of the cemented carbide is laser cladded and modified in the stress area of the hinge surface to ensure the hardness and deformation resistance of the hinge.