Butterfly valves have long been a cornerstone of industrial fluid control systems. They belong to the family of quarter-turn valves, offering fast and reliable operation with minimal space requirements. Unlike gate or globe valves that rely on linear motion, butterfly valves regulate flow through a rotating disc mechanism, making them an ideal choice for applications demanding compactness, speed, and cost efficiency.

Among the many variations, the concentric butterfly valve—also known as a centric butterfly valve or resilient-seated butterfly valve—stands out as one of the most widely used designs across industries. These valves are particularly recognized for their simplicity, affordability, and effective sealing performance in low to medium pressure applications. They are widely used in sectors such as water treatment, HVAC, chemical processing, and food production, where dependable isolation and easy operation are essential.

In essence, a concentric butterfly valve is engineered to solve the tightening and sealing challenges that occur between the disc and the seat during valve operation. Its design ensures smooth movement and tight shut-off, even when subjected to frequent cycling or exposure to abrasive and corrosive media.

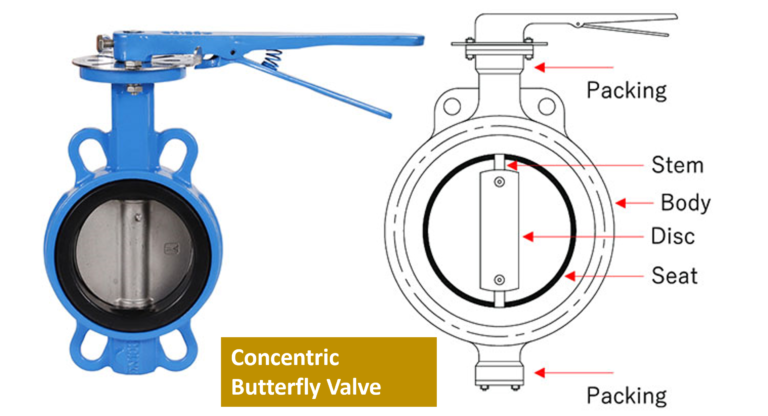

The defining feature of a concentric butterfly valve lies in its geometry. The stem axis, disc center, and body centerline all align along the same central axis. This symmetric layout creates a balanced torque during operation and ensures that the valve disc maintains an even contact with the soft seat material around its perimeter.

When the valve is in a closed position, the disc presses uniformly against the resilient seat, creating a tight seal. When it opens, the disc rotates a quarter-turn (90 degrees) to allow the fluid to flow freely through the passage. Because of its simple mechanical structure and ease of actuation, the concentric butterfly valve can be operated manually (via lever or gear operator) or automatically (via pneumatic, electric, or hydraulic actuators).

Another notable advantage of this configuration is that the valve seat fully lines the body, preventing the fluid from contacting the metal surfaces of the body itself. This not only extends the valve’s lifespan but also makes it suitable for handling corrosive or chemically aggressive media.

A concentric butterfly valve typically consists of the following key components:

Valve Body – The main housing that supports all internal components. It’s usually made from ductile iron, cast iron, stainless steel, aluminum bronze, or PVC, depending on the application and the media being handled.

Disc – The rotating element that controls the flow. The disc is positioned in the center of the valve and serves as the main shut-off component. Common materials include stainless steel, aluminum bronze, or coated steel, chosen for their corrosion resistance and strength.

Seat (Liner) – A soft, replaceable sealing element made from elastomeric or polymeric materials such as EPDM, NBR, Viton, Silicone, PTFE (Teflon), Hypalon, or Neoprene. The seat ensures tight shut-off and protects the valve body from the process fluid.

Stem (Shaft) – The component that transmits torque from the handle or actuator to the disc. It is generally made from stainless steel or high-strength alloys and supported by bushings to reduce wear.

Actuator or Handle – The operating mechanism that turns the valve disc. Manual levers are common in small sizes, while larger valves often use gear operators, pneumatic cylinders, or electric motors.

This simple yet efficient design minimizes the number of components and moving parts, reducing potential points of failure. It also allows for lightweight construction and compact dimensions, which make installation and maintenance straightforward.

The operation of a concentric butterfly valve is both intuitive and effective. When the handle or actuator turns the stem, the disc rotates within the valve body.

In the open position, the disc aligns parallel to the flow, offering minimal resistance and allowing fluid to pass through almost unobstructed.

In the closed position, the disc rotates perpendicular to the flow, pressing tightly against the valve seat to block passage completely.

The concentric alignment ensures that the disc and shaft are centrally positioned, meaning the sealing action is purely a result of elastic deformation of the seat material. This design eliminates the need for complex offset geometries, simplifying both production and operation.

In essence, the concentric butterfly valve functions as a low-torque, high-cycle shut-off valve, ideal for applications where frequent opening and closing are required.

Concentric butterfly valves are used in a broad spectrum of industries and systems, thanks to their versatility and low maintenance requirements. Common applications include:

Water and wastewater treatment systems

HVAC and building services

Chemical and pharmaceutical processes

Food and beverage production

Pulp and paper mills

Power generation (low-pressure cooling water systems)

Marine and shipbuilding applications

Their compatibility with soft-seated materials also makes them suitable for handling slurries, light solids, and corrosive liquids—although not at high pressures or temperatures.

Concentric butterfly valves provide several advantages that make them one of the most practical and economical flow control solutions in the market.

The alignment of the stem, disc, and body center simplifies the valve’s overall structure. Fewer components mean lower manufacturing costs, reduced weight, and smaller installation space compared to other valve types like gate or ball valves.

As a quarter-turn valve, the concentric butterfly valve requires only a 90° rotation to go from fully open to fully closed. This ensures rapid isolation and precise flow regulation, making it ideal for automated systems.

The resilient seat ensures bubble-tight shut-off when properly designed and installed. The soft seat materials deform elastically against the disc edge, creating a secure seal even under low differential pressures.

These valves are generally less expensive to manufacture, install, and maintain than other isolation valves. Their lightweight construction also reduces the need for heavy support structures or large actuators.

The availability of various seat materials (EPDM, NBR, Viton, etc.) allows the valve to handle a wide range of fluids, including potable water, seawater, chemicals, and mild abrasives.

Because of their simple geometry and minimal moving parts, concentric butterfly valves require little maintenance. The seats are usually replaceable, allowing for easy refurbishment without replacing the entire valve.

The flat surfaces near the disc stem interface closely with the seat ring, effectively preventing leaks. As the valve closes, the seat compresses elastically, ensuring tight shut-off without permanent deformation.

While concentric butterfly valves are efficient for many general-purpose uses, they do have certain limitations:

The concentric design requires a flexible, deformable seat to achieve sealing. As such, metal-seated configurations are not suitable, restricting their use to soft-seated applications only.

These valves are not recommended for high-pressure or high-temperature systems, as the soft seat materials can deform, degrade, or lose elasticity under extreme conditions.

Continuous operation or throttling near the closed position may cause wear or fatigue in the seat material, requiring periodic replacement.

While they can regulate flow, concentric butterfly valves are primarily isolation valves. For precise control, eccentric or triple-offset butterfly valves are better suited.

To ensure long-term reliability and efficiency, regular maintenance is recommended. Here are key steps to maintain optimal valve performance:

Leak Inspection: Regularly check for leaks around the disc, seat, or stem areas, especially after extended service or exposure to harsh chemicals.

Seal Replacement: Over time, seat materials may degrade. Inspect seals periodically and replace them when deformation or cracking is observed.

Actuator Function: For automated systems, verify actuator calibration and smooth operation. Lubricate moving parts as necessary.

Cleaning: Keep the valve body and disc clean from deposits or buildup that could interfere with sealing.

Operational Testing: Periodically operate the valve through its full range to ensure the disc moves freely and without obstruction.

By following these maintenance practices, operators can significantly extend the service life and operational reliability of concentric butterfly valves.

The lifespan of a concentric butterfly valve varies based on factors such as material selection, operating environment, and maintenance frequency. Under normal service conditions with proper maintenance, these valves can function effectively for 8 to 15 years or more.

Using high-quality elastomeric seats and corrosion-resistant materials can further increase longevity, especially in chemically aggressive or saline environments. Additionally, avoiding excessive pressure or temperature fluctuations will minimize wear and prolong the valve’s sealing integrity.

When comparing valve designs, it’s important to understand where concentric butterfly valves fit among their counterparts:

The disc and stem share the same centerline, offering simple construction and tight sealing for low-pressure applications.

The stem is offset from both the center of the disc and the valve body, reducing friction and allowing the disc to move away from the seat as it opens. This design supports higher pressures and temperatures.

With three levels of offset, these valves provide bubble-tight sealing even under extreme conditions, making them ideal for steam, gas, and high-temperature applications.

In short, while concentric butterfly valves excel in cost efficiency and soft sealing, eccentric types are preferred for demanding, high-performance environments.

The concentric butterfly valve remains one of the most reliable and versatile choices for fluid control in modern industries. Its simple design, effective sealing, and affordability make it indispensable in water systems, chemical processing, and numerous general industrial applications.

Though it may not withstand the extreme pressures or temperatures that eccentric designs can handle, its ease of installation, low maintenance demands, and broad material compatibility make it a go-to solution for everyday flow regulation and isolation needs.

As industries continue to evolve and prioritize efficiency, concentric butterfly valves will remain a foundational component of cost-effective and dependable fluid management systems.