Automatic Recirculation Valves (ARVs), also known as minimum flow valves, play a critical role in protecting centrifugal pumps and ensuring the efficiency of liquid handling systems. These valves maintain a constant minimum flow rate through the pump, safeguarding it from harmful conditions such as cavitation, overheating, and dry running, which can cause severe damage or lead to premature failure.

Designed to handle challenging operating environments, ARVs typically operate within a temperature range of -10°C to 200°C, making them suitable for various industrial applications—from power plants and refineries to chemical processing and water treatment facilities. By automatically controlling the recirculation flow, ARVs reduce the need for manual intervention, improving operational safety, reliability, and system longevity.

Their intelligent design ensures that pumps always operate within safe parameters, minimizing maintenance needs and enhancing energy efficiency across the entire system. In essence, the ARV is an automatic safeguard that keeps your process running smoothly, efficiently, and safely.

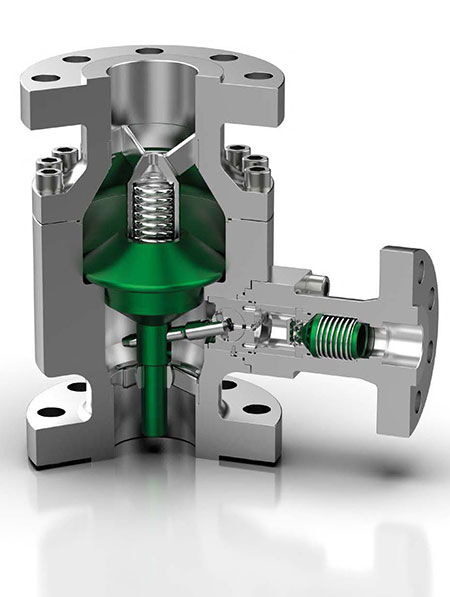

An Automatic Recirculation Valve (ARV) is a self-acting, compact device installed on the discharge line of a centrifugal pump. It automatically ensures that a minimum flow of liquid continues to circulate through the pump, even when the main outlet flow decreases or stops entirely. This is especially crucial during start-up, shutdown, or low-load operations.

Unlike traditional bypass systems that rely on multiple components—such as control valves, check valves, and orifice plates—an ARV integrates these functions into a single, streamlined unit. This compact configuration saves space, simplifies installation, and reduces both capital and maintenance costs.

Prevents reverse flow into the pump and helps stabilize system pressure, protecting against surges or fluctuations.

Detects when main flow drops below the set minimum threshold. At this point, a spring-loaded disc or piston automatically opens a bypass passage, allowing liquid to flow back into the pump’s suction line or a storage tank.

The bypass route channels excess liquid safely while reducing pressure to protect downstream components. It ensures continuous liquid movement through the pump even during low or zero process flow.

This self-contained mechanical operation means the valve requires no external power, sensors, or control signals, which enhances reliability and reduces system complexity. It reacts purely based on the process flow and pressure conditions.

The Automatic Recirculation Check Valve (ARC Valve) is typically installed on the pump discharge branch or directly in the discharge line near the pump. A bypass branch connects the valve to a recirculation line, which returns liquid to the suction side of the pump or a separate tank.

Here’s how the valve operates under different system conditions:

When there is little or no demand from the process line, the valve automatically opens the bypass. This allows the Minimum Continuous Flow (MCF) to circulate back to the pump, preventing overheating and maintaining hydraulic stability.

As process demand begins to rise, the valve senses the higher flow rate and gradually modulates between the process and bypass lines. It ensures that the total pump flow always stays above the MCF value.

Once the process demand exceeds the required minimum flow, the bypass line closes completely, and all the pumped fluid is directed to the main process line.

If demand falls again below the MCF threshold, the bypass automatically reopens, diverting a portion of the fluid through the recirculation line.

Through this continuous modulation, the ARV ensures that the pump never runs under unsafe low-flow conditions, thereby preventing mechanical and thermal stress.

Centrifugal pumps are designed to operate within specific flow ranges. Operating below the minimum flow can lead to excessive heat build-up, vibration, and cavitation—a destructive phenomenon where vapor bubbles collapse and damage impeller surfaces.

The automatic recirculation valve eliminates this risk by guaranteeing the required minimum flow rate. It prevents the pump from running dry, overheating, or experiencing damaging pressure spikes. This protection leads to:

Extended pump lifespan

Reduced frequency of repairs

Improved system stability

With continuous protection, pumps can operate for longer periods with greater reliability, even in demanding industrial applications.

An ARV does more than protect pumps—it optimizes system efficiency. By automatically adjusting flow based on real-time process demand, it prevents energy wastage and reduces operating costs.

For example:

When process demand is low, the valve only allows the necessary minimum flow through the pump.

When demand increases, it adjusts seamlessly, ensuring no energy is wasted recirculating unnecessary liquid.

This intelligent regulation can result in up to 90% energy savings compared to systems that use continuous bypassing or manual control methods. Additionally, the valve’s efficient fluid management can reduce heat generation and lower water heating energy consumption by nearly one-third.

The benefits include:

Optimized energy use

Reduced operational costs

Lower environmental impact

Longer pump and motor service life

Traditional pump protection systems often involve multiple components—check valves, control valves, flow regulators, and bypass piping. These systems take up space, require complex wiring or controls, and add to installation costs.

An ARV consolidates all these features into a single integrated valve, offering a compact and efficient alternative. It simplifies piping design, reduces potential leak points, and allows for easier system commissioning.

Additionally, the ARV’s mechanical design requires no external actuation or power supply, making it especially suitable for remote installations or safety-critical environments.

Maintenance is one of the major cost factors in pump operations. Conventional systems often require frequent inspection and part replacement due to seal wear, leaks, or control component failures. The ARV addresses these challenges through its robust and self-regulating design.

Key benefits include:

Fewer moving parts, reducing wear and tear.

Improved sealing technology, minimizing leakage.

Automatic operation, reducing human error.

These features result in:

Lower maintenance frequency

Fewer unexpected shutdowns

Extended service intervals

Reduced spare part costs

As a result, plant operators enjoy greater system uptime and lower lifecycle costs, leading to better overall productivity.

Automatic recirculation valves are widely used in various industries where centrifugal pumps play a key role in liquid handling. Common applications include:

Power Generation: Protecting boiler feedwater pumps and condensate pumps from low-flow damage.

Petrochemical and Refining: Ensuring reliable circulation of hydrocarbons and process fluids under varying load conditions.

Chemical Processing: Maintaining stable flow in reactors, cooling systems, and transfer pumps.

Water Treatment Plants: Preventing pump damage during fluctuating demand cycles.

Marine and Offshore Systems: Providing dependable flow control in ballast water, cooling, and fuel transfer systems.

Pharmaceutical and Food Industries: Ensuring precise fluid control where hygiene and reliability are essential.

In all these sectors, ARVs serve as a key safety and efficiency component, offering long-term operational stability.

Automatic recirculation valves are engineered to perform reliably under a variety of process conditions. Manufacturers typically offer multiple material configurations to match system requirements, including:

Carbon Steel (ASTM A105): Suitable for general-purpose industrial systems.

Stainless Steel (ASTM A182 F316/F304): Provides superior corrosion resistance for chemical and marine environments.

Alloy Steels and Duplex Stainless Steels: Used in high-pressure or corrosive service conditions.

Bronze or Aluminum Bronze (C95800): Ideal for seawater and marine applications.

Pressure ratings generally range from Class 150 to Class 2500, with options for flanged, butt-welded, or socket-welded ends depending on installation requirements.

Manufacturers often design ARVs according to international standards such as API 6D, ASME B16.34, and DIN EN 12266, ensuring global compatibility and high-quality assurance.

Even though ARVs are designed for minimal maintenance, regular inspection can ensure reliable long-term performance. Recommended practices include:

Periodic visual checks for leaks or abnormal vibrations.

Monitoring flow and pressure differentials to confirm the valve is modulating correctly.

Inspecting internal components during scheduled shutdowns to assess seat and disc wear.

Cleaning or replacing worn parts as needed.

If a system exhibits abnormal pump noise, overheating, or pressure instability, the ARV should be one of the first components checked for partial blockage or wear. However, due to their simple mechanical design, ARVs typically provide years of maintenance-free operation under normal conditions.

As industries move toward digitalization and automation, new ARV models are being developed with smart monitoring capabilities. Integrated sensors can provide real-time feedback on flow rates, temperature, and pressure, allowing predictive maintenance and early fault detection.

Moreover, advancements in material science—such as ceramic coatings and advanced polymers—are further extending the service life of valves in highly corrosive or abrasive conditions. These innovations continue to make ARVs more efficient, durable, and adaptable to modern process control systems.

The Automatic Recirculation Valve (ARV) is a critical safeguard for centrifugal pumps, ensuring they always operate within safe and efficient parameters. By automatically maintaining minimum flow, it prevents costly damage from cavitation, overheating, and dry running.

Through its self-contained mechanical design, it simplifies installation, enhances system reliability, and reduces both maintenance and energy costs. Whether in power generation, chemical processing, water treatment, or marine systems, ARVs deliver unmatched protection and performance.

As industrial systems continue to evolve, ARVs will remain indispensable for optimizing pump performance, improving energy efficiency, and extending equipment lifespan — ensuring smooth, safe, and efficient operation across diverse industries worldwide.

Next: What Is A Floating Ball Valve?

Previous: What Is a Concentric Butterfly Valve?