Regarding ball valves, the American Petroleum Institute has two standard specifications, API 6D "Specification for Pipelines and Their Valves" and API 608 "Flanged, Threaded and Welded Metal Ball Valves". These two standards provide detailed specifications for ball valves. A preliminary interpretation of the regulations and requirements for ball valves in API 6D and API 608 is made, and engineering practice is combined to clarify the differences and connections between API 6D ball valves and API 608 ball valves in terms of structural design, performance requirements and test methods in this article.

1. The relationship between API 6D and API 608

API 6D ball valves are used in the pipeline system of the oil and natural gas industry, including long-distance oil and gas pipelines and collection pipelines with all levels, which are equivalent to transportation outside the station area, including ASME B31.4 and B31.8 pipelines, with a diameter of NPS 4 to 60. Most of them have large diameters, 95% of which are above 10 inches, and the pressure ratings are 150, 300, 400, 600, 900, 1500 and 2500. They generally have fixed ball structures, and their inlet ends are sealed. API 608 ball valves are used in petroleum, petrochemical industry and industry. They are mainly used in ASME B31.3 process pipelines with a diameter of NPS 1/4 to 24. Most of them have smaller diameters and pressure ratings of 150, 300, 600, 800. They usually have floating ball structures, and their outlet ends are sealed.

API 608 is an additional design, operation and performance requirement in addition to the requirements specified in ASME B16.34 "Flanges, Threaded and Welded Valves", and is for general industrial users. The American Petroleum Institute formulated the API 6D "Specifications for Pipelines and Pipeline Valves" due to the particularity of long-distance pipeline engineering, which shows the different structure and functions between API 6D ball valves and AP1608 ball valves.

API 6D and API 608 ball valves have their own characteristics according to different working conditions and requirements, and they constitute a complete specification for ball valves in the petrochemical field. A preliminary interpretation and analysis of the two ball valve standards are carried out based on engineering practice.

2. The requirement analysis of the ball valve

2.1 Structural and functional requirements

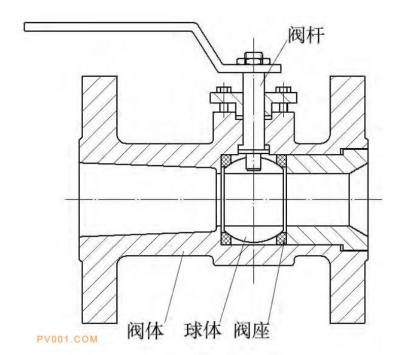

Ball valves are divided into floating ball valves and trunnion ball valves according to the structure of the ball. The typical structure of a floating ball valve is shown in Figure 1. The ball has no supporting shaft, and it is supported by the valve seats at the inlet and outlet ends of the valve. The valve stem and ball are movably connected. When the valve is closed, the ball is pushed to the valve seat at the outlet end of the valve under the action of the medium pressure to make it pressured and sealed. This kind of ball valve is sealed at the outlet end (after the valve), and has the characteristics of simple structure, convenient manufacture, low costs and reliability, which has been widely used in process pipelines.

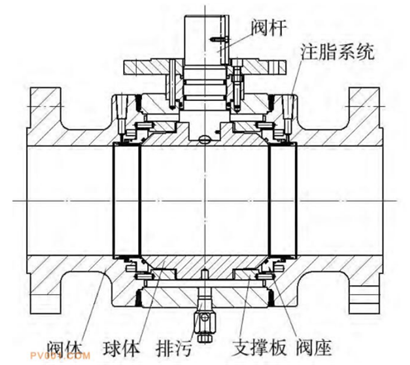

The structure of the trunnion ball valve's support plate is shown in Figure 2. The ball is supported by a support plate fixed to the valve body, and the valve seat is a piston effect valve seat. Under the action of the medium pressure, the valve seat approaches the sphere, so that the seat's sealing ring is pressed tightly on the sphere, and the sealing specific pressure is generated to achieve the purpose of sealing. The force generated by the pressure of the medium in front of the valve on the ball is all transmitted to the bearing, and the ball will not move to the rear seat of the valve; the valve seat will not bear excessive pressure. This kind of ball valve is sealed at the inlet end (in front of the valve). It has the characteristics of small opening torque and stable sealing performance. It is suitable for long-distance pipelines with high pressure and large diameters.

The API 608 ball valve is used in the process pipeline of petrochemical industry. Its function is to connect or cut off the medium. It is often used for high-temperature and high-pressure, toxic, harmful, flammable and explosive, corrosive and continuous operation working conditions, and high requirements are put forward for sealing, materials, anti-corrosion and other aspects of the valve. The API 608 ball valve has a fixed ball structure and a floating ball structure, and a floating ball structure is generally adopted.

Figure 1 Floating ball valves

API 6D ball valves are used in long-distance pipelines. In addition to the function of connecting or cutting off the medium, the ball valve must also have the functions of sewage discharge, venting, overpressure relief, grease injection and online inspection for leakages due to the particularity of long-distance pipelines. API 6D ball valves all adopt a fixed ball structure.

Figure 2 Fixed ball valves

API 6D pipeline ball valves should have the functions of discharging and venting:

(1) Verify the sealing performance of the valve seat during the valve factory test. (2) Drain the dirt in the valve cavity before the pipeline is put into production. (3) Check the sealing of the valve online when it is put into operation. (4) When rushing to repair, they are used for discharging and venting on the pipeline.

In order to ensure the safety of urgent repair, reduce the impact on the environment and costs of venting, the discharge and venting of the pipeline ball valve are particularly important. The discharge and venting must be designed in strict accordance with the API 6D specifications and meet the specifications for the size of the discharge and vent port. For the ball valve seat with the function of draining and venting, each valve seat can withstand the full pressure difference outside (DBB functions); isolate the upstream and downstream media, and achieve the purpose of safe discharging and venting.