A control valve serves as a regulating device crucial for managing pressure flow across diverse materials in industrial settings, including steam, gas, hot water, and chemicals, integral for producing final products. It plays a vital role in the control process loop, ensuring quality production by maintaining variables at desired set points. Employing various sensors and detectors, minute changes are detected and relayed to control valves through specialized software.

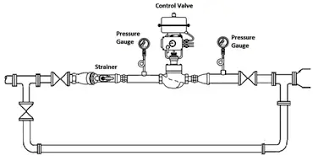

The efficient operation of a control valve relies on a complex assembly process often overlooked. A typical assembly line comprises the main body, internally trimmed components, and an actuator supplying electrical or pneumatic power. Control valve accessories vary based on industry needs, encompassing flow pressure regulators, sensors, and limit switches.

Why Control Valves are Essential in Industrial Settings:

In complex industrial facilities, numerous control loops operate seamlessly in the background, managing various parameters like flow rate, pressure, temperature, and material level. These loops interact to maintain optimal process speed.

Control valves play a pivotal role as the final component of these loops, tasked with correcting load disturbances that may arise during variable control. They ensure the industrial plant remains in the desired state, facilitating uninterrupted and high-quality product manufacturing.

Understanding the Functionality of Control Valves:

Often overlooked but indispensable, control valves are vital components within mechanical control loops. Proper selection is critical to maintaining product quality and operational continuity within industrial plants.

A typical control loop consists of sensors, transmitters, and controllers. Sensors detect load disturbances, transmitting data to collectors. The control unit sets fixed conditions for process variables, comparing current data with preset conditions and generating corrective signals when necessary. These signals are then relayed to the control element, which oversees in-process adjustments.

In essence, sensors act as eyes, transmitters as messengers, collectors as brains, and control elements as hands within a control loop.

Considerations for Control Valve Installation:

The installation of a control valve is as crucial as any other physical component within a control loop, directly impacting an industrial unit's profitability. Faults during installation can lead to plant failure, despite advanced machinery.

01 Adhering to Manufacturer Instructions:

Following the manufacturer's installation guide and cautions ensures accurate operation. The instruction manual provides recommendations, do's and don'ts, and safety measures, aiding in avoiding mishaps during and after installation.

02 Control Valve Inspection:

Despite precautions taken during production and transportation, damage during shipment is possible. Thoroughly inspecting the valve before installation can save time and money, ensuring any issues are addressed before installation begins.

03 Pipeline Cleaning:

Before installation, ensure the pipeline is thoroughly cleaned to prevent damage to the valve's seating surface. Foreign materials like metal flakes or welding slag can hinder proper tightening, leading to leakage.

04 Sealant Application:

Applying suitable sealant to screwed connections prevents loosening and leakage. Sealant should be applied to male pipe threads to avoid valve body penetration, which can cause sticking and valve shutdown.

05 Orientation During Installation:

While control valves can be installed in various positions, vertical installation is often recommended. Horizontal placement can exert additional weight, causing premature wear, breakage, and leakage.

06 Flanged Connection Tightening:

For valves with nuts and bolts, tighten connections in a star pattern for a superior seal and resistance to leakage compared to one-sided patterns.