One of the key features of globe valves is their spherical shapes, which allows for precise regulation of fluid flow. This shape enables the valve to open and close gradually, reducing the risk of sudden pressure changes that could damage the system. Additionally, globe valves have a disc or plug that moves up and down to control the flow, providing excellent throttling capabilities. Another advantage of globe valves is their ability to handle high pressures and temperatures. Their robust construction makes them suitable for use in demanding environments such as power plants or oil refineries. Moreover, globe valves can be made from a variety of materials including stainless steel, cast iron, or bronze, allowing for compatibility with different types of fluids.

Despite their numerous advantages, globe valves do have some limitations. One drawback is their relatively high-pressure drop compared to other types of valves. This means that more energy is required to push fluids through a globe valve compared to alternatives like ball valves or gate valves.

In conclusion, globe valves are an important component in fluid control systems due to their reliability and versatility. Their unique design allows for precise regulation while withstanding high pressure and temperatures. However, it's essential to consider factors such as pressure drop when selecting a valve type for specific applications.

Globe valves with two valve stems

Depending on the position of the valve stem thread of the globe valve, it can be divided into globes valves with upper threaded stems and lower threaded stems.

1. Globe valves with upper threaded valve stems

Globe valves with upper threaded stems have been a fundamental component of industrial systems for centuries. These valves are known for their reliable performance and ability to control the flow of various fluids, making them indispensable in a wide range of applications. One key feature of globe valves with upper threaded stems is their threaded stem design. This allows for precise control over the opening and closing of the valve, enabling operators to regulate fluid flow with accuracy. The threaded stem also ensures a tight seal, preventing any leakage or loss of pressure within the system.

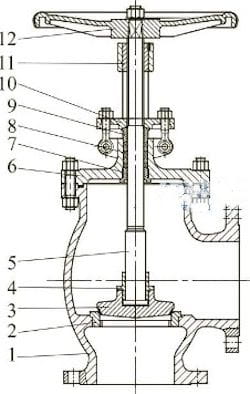

Figure 1 shows the typical structure of angle globe valves with upper threaded valve stems. The transmission thread is located on the upper part of the valve stem and outside the bonnet packing box. The thread does not contact the medium, so it will not be corroded by the medium and is easy to lubricate.

The upper threaded valve stem is not easy to skew, which can ensure the good alignment of the valve disc and the valve seat, which is conducive to sealing. The design depth of the packing box is not limited, which makes it easy to prevent external leakage. The upper threaded stem is suitable for globe valves with larger diameters, high temperature, high pressure or corrosive media.

Figure 1 Angle globe valves

1. Valve bodies 2. Valve seats 3. Valve discs 4. Valve disc covers 5. Valve stems 6. Valve bonnets 7. Upper sealing seats 8. Packing 9. Packing sleeves 10. Packing gland 11. Valve stem nuts 12. Handwheels

2. Globe valves with lower threaded valve stems

One of the key advantages of globe valves with lower threaded stems is their ability to provide accurate throttling control. The threaded stem allows for fine adjustments, enabling operators to regulate flow rates with precision. This level of control is crucial in applications where even slight changes in flow can have significant consequences. These valves offer excellent sealing capabilities due to their design. The globe-shaped body ensures a tight seal when the disc or plug is fully closed, preventing any leakage. This feature makes them suitable for handling both liquids and gases under high pressure. Furthermore, globe valves with lower threaded stems are known for their durability and reliability. They are constructed from robust materials such as stainless steel or cast iron, ensuring long-lasting performance even in harsh operating environments.

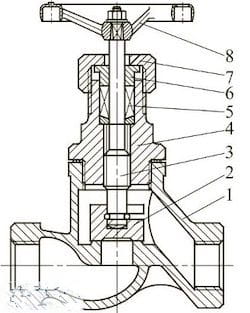

Figure 2 shows the typical structure of the globe valve with the lower threaded drive stem. The driving thread is located at the lower part of the valve stem, in the valve body cavity, and is in contact with the medium, which is easily corroded by the medium and cannot be lubricated. For the medium with high viscosity and suspended solids, the liquid is easy to condense, and the thread will be jammed.

The advantage of the lower threaded stem is that the length of the stem is relatively short, which can reduce the opening height of the valve. It is usually used for globe valves with small diameters, normal temperature, non-corrosive, and relatively clean media.

Figure 2 Globe valves connected with bonnets by threads